CAMT

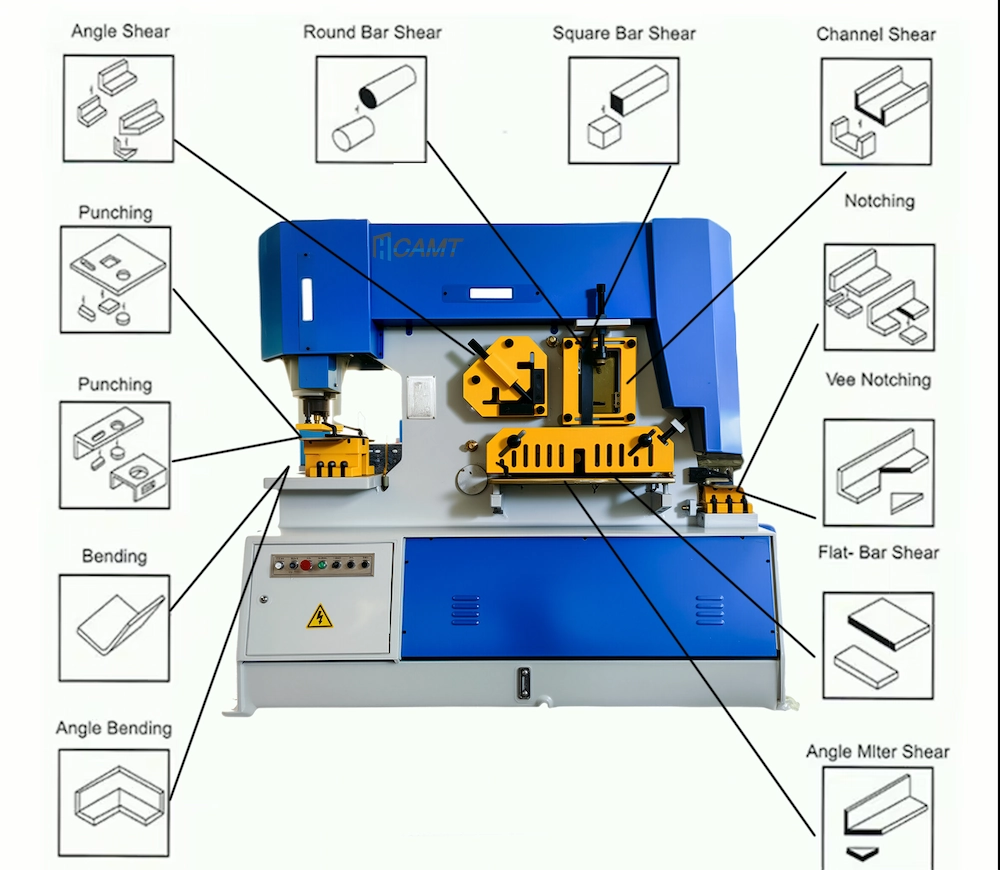

Hydraulic Ironworker Machine

CAMT

Q35Y Hydraulic Ironworker

Conbined Punching & Shearing Machine

CAMT Ironworker is ideal equipment for cutting all kinds of angle steel, I-beam, U-shape steel, right angle or 45 degree angle steel. Multi-workstations make it possible to finish series operations simultaneously on one machine, such as punching, shearing and notching, Dual-piston-type combined punching and shearing machine allows two-man operation at the same time (stamping +another work station).

Hydraulic transmition and mechanical conventional pressing are adopted.There are five stations,in which a is an independent station and combined station. The stroke of pumching and shearing is adjustable.Different cutters can be selected to cut, punch, cut, chamber and die shear flat steel,square steel,round steel,bar,angelk steel,channel steel,I-beam,Z-beam and other common solid steel materials.The worktable is equipped with T-groove and ruler,which is convenient for the free installation and adjustment of tooling and die.Double foot switch,free and independent operation,double efficiency.

CAMT Hydraulic Ironworker Machine

Incorporates the Following Attributes and Capabilities

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Punching: effective punching can be achieved with the machine, and stamping die is easy to be replaced

Bar cutting: you can quickly cut the round bar and square steel

Metal Sheet Bending: it is very easy to fulfill the daily metal sheet bending work by making the bending moulds.

Notching: The machine is equipped with a large-shaped slotting blade head, which can meet your general use, as to, special shaping blade head can be customized.

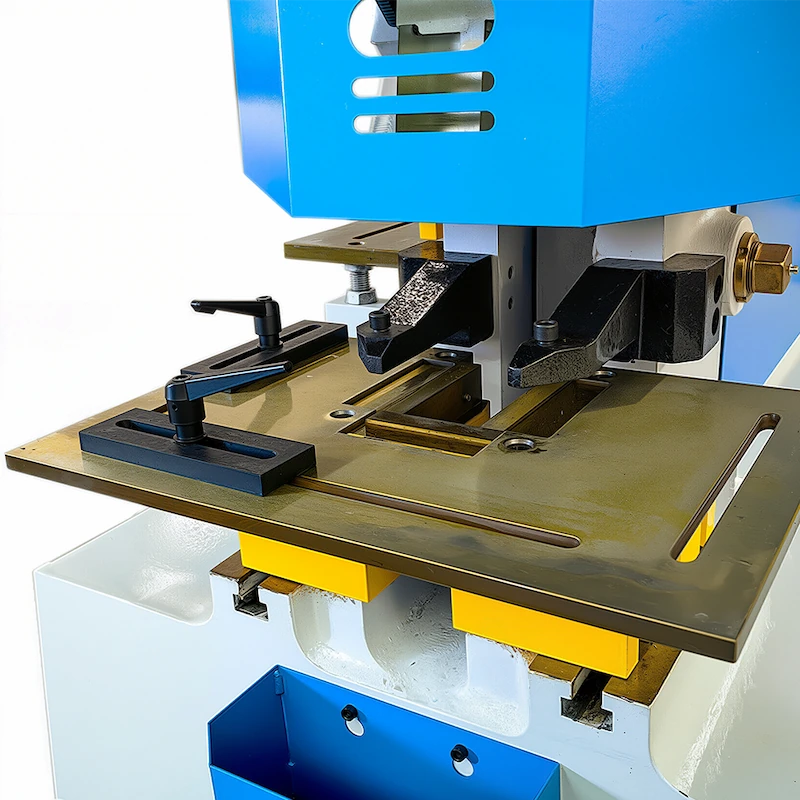

Punching Station of Ironworker

Full range of universal punches and dies are available. Unique style allows for large angle iron punching and large channel punching.arge viewing window on stripper swing away design for ease of operation. Large two piece gauging table with rulers and stop as standard fittings. Quick change coupling nut and sleeve for rapid replacement of change.

Flat Bars Shearing Station of Ironworker

- Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round / square bar, channel / beam cutting. Large strong guarding or max safety.

- The angle shear has the ability to cut angle at 45° both top and bottom leg. This gives the operator the ability to make a picture frame corner for perfect welds. Diamond shaped blade for quality cuts that is minimal material lost and deformity. T

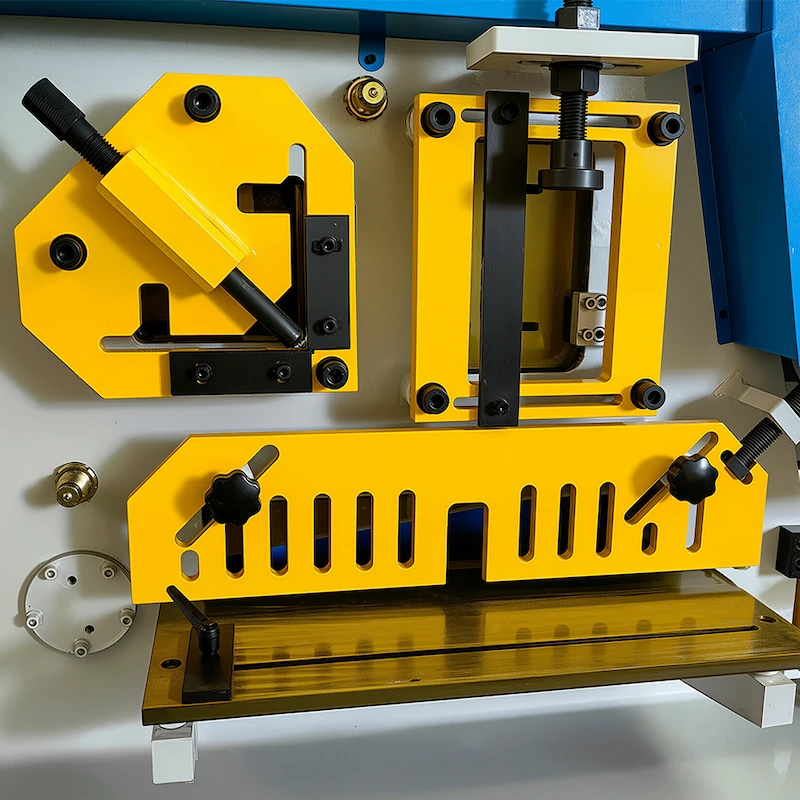

Notching Station of Ironworker

- Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.

- Notching is a metal-cutting process used on sheet metal or thin barstock, sometimes on angle sections or tube.

Technical Parameter of CAMT Ironworker

| Model | Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 |

|---|---|---|---|---|---|---|

| Pressure | 65T | 90T | 120T | 160T | 200T | 250T |

| Max.cutting thickness | 16MM | 20MM | 25MM | 30MM | 40MM | 50MM |

| Plate strength | ≤450N/MM2 | ≤450N/MM2 | ≤450N/MM2 | ≤450N/MM2 | ≤450N/MM2 | ≤450N/MM2 |

| Cutting angle | 7° | 8° | 8° | 8° | 8° | 8° |

| Shearing size of one stroke | 16X250MM 8X400MM | 20X330MM 10X480MM | 25X330MM 16X600MM | 30X330MM 20X600MM | 35X400MM 25X700MM | 40X400MM 30X750MM |

| Ram stroke | 80MM | 80MM | 80MM | 80MM | 80MM | 80MM |

| Number of stroke | 12CPM | 10CPM | 10CPM | 10CPM | 10CPM | 10CPM |

| Throat depth | 300MM | 355MM | 400MM | 600MM | 600MM | 600MM |

| Punching thickness | 16MM | 20MM | 25MM | 26MM | 35MM | 40MM |

| Max.Punching diameter | 25MM | 30MM | 35MM | 38MM | 40MM | 40MM |

| Power of main motor | 4KW | 5.5KW | 7.5KW | 11KW | 15KW | 18KW |

| Overall dimension(MM) | 1650X800X1800 | 1830X800X1900 | 2200X1000X2100 | 2600X1050X2400 | 2900X1300X2650 | 3000X1440X2450 |

| Weight | 1600KGS | 2200KGS | 3800KGS | 6300KGS | 8800KGS | 12800KGS |

| Q35Y-16 | Q35Y-20 | Q35Y-25 | Q35Y-30 | Q35Y-40 | Q35Y-50 | |

|---|---|---|---|---|---|---|

| Round bar(MM) | φ45 | φ50 | φ60 | φ65 | φ70 | φ80 |

| Square bar(MM) | 40X40 | 50X50 | 50X50 | 55X55 | 60X60 | 65X65 |

| Equal Angle | ||||||

| 90°shearing | 125X125X12 | 140X140X12 | 160X160X14 | 180X180X16 | 200X200X18 | 200X200X20 |

| 45°shearing | 50X50X5 | 50X50X5 | 60X60X6 | 60X60X6 | 100X100X10 | 120X120X10 |

| T-Bar | ||||||

| 90°shearing | 125X125X12 | 140X140X12 | 160X160X14 | 180X180X16 | 180X180X16 | 180X180X16 |

| 45°shearing | 60X60X8 | 70X70X10 | 80X80X10 | 80X80X10 | 80X80X10 | 80X80X10 |

| I-BAR(MM) | 125X74X5 | 160X86X6 | 200X102X9 | 280X124X10.5 | 300X126X11 | 320X130X10 |

| Change I(MM) | 126X53X5.5 | 160X60X65 | 210X75X9 | 280X86X11.5 | 300X89X12 | 320X92X12 |