CAMT

Y32 4 Column Hydraulic Press Machine

CAMT

Y32 4 Column Hydraulic Press Machine

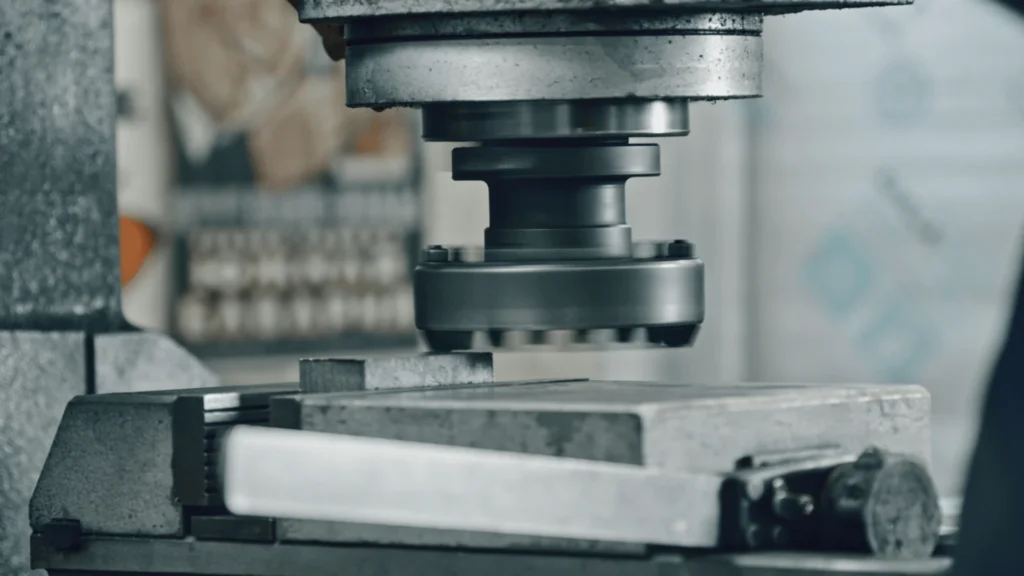

CAMT four-column hydraulic press is a heavy-duty industrial pressing equipment designed based on Pascal’s hydraulic principle. Its core feature is a closed-frame structure consisting of four high-strength columns. Utilizing advanced hydraulic transmission technology, the machine generates linear pressing force through a hydraulic power unit driving the main cylinder, coupled with a precision guiding system to ensure stable movement of the sliding ram. It enables high-precision forming of various materials, including metals, composites, and plastics.

In terms of structural design, the four-column configuration forms a robust mechanical load-bearing system. The columns undergo quenching and tempering heat treatment and are equipped with adjustable nuts, ensuring exceptional parallelism accuracy (typically ≤0.1mm/m) even under long-term eccentric load conditions. The hydraulic system employs two-way cartridge valve integration technology combined with variable displacement piston pumps to achieve stepless pressure regulation (standard range: 10-5000 tons). It offers technical advantages such as low energy consumption, rapid response (idle speed up to 300mm/s), and stable pressure holding (pressure fluctuation ≤±0.5MPa).

Add Your Tooltip Text Here

Add Your Tooltip Text Here

High Stability

Wide Tonnage Range

Energy-Efficient

Flexible Operation

CAMT Powerful Press Solution

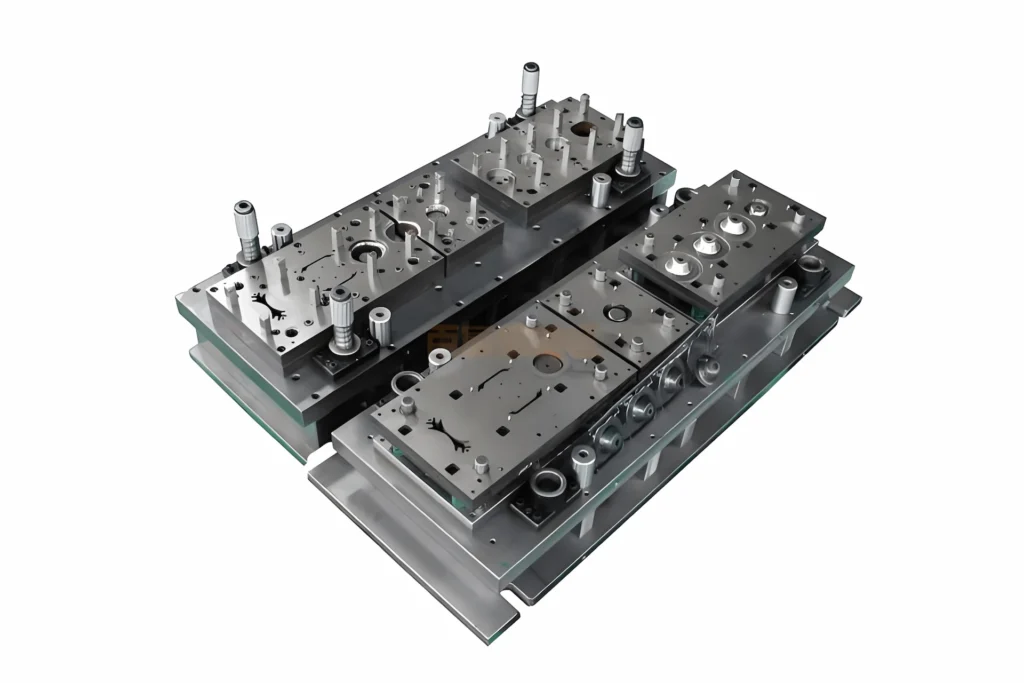

Pressure processing machine that utilizes hydraulic transmission principles and features a four-column structure for support. It employs a hydraulic system to drive the sliding ram for up-and-down movement, enabling processes such as stamping, stretching, bending, forming, and pressing of metal or non-metallic materials. The four-column design ensures stability, making it suitable for high-precision, high-tonnage industrial applications.

Functional Configuration of Hydraulic Press

Typically includes the following core components

- Structure design is optimized by computer, with three-beam andfour column structure; this equipment is simple, economic and useful.

- Hydraulic control adopt insert type compact valve system, with reliable operation, long service life, minimized hydraulic shock, minimized duct connection and possible leak point.

- Independent electric control system which is reliable, direct-in-running, and convenient for maintaining.

- Adopt concentrated button control system, which is adjustable and has two operation models, viz. both hands model and single circulation model.

- Two operation model, viz. pressure regulation and stroke regulation which can be selected through operational panel, and has the character of pressure-keeping and time-delaying.

- Work pressure and stroke can be adjusted according to the requirement within the specified range.

Press Application About Press Machine

Widely used in the following industries

- Metal Processing: Stamping, stretching, riveting, pressing, and straightening.

- Plastic Products: Compression molding, SMC/BMC composite material pressing.

- Powder Metallurgy: Metal powder compaction.

- Rubber Industry: Vulcanization and compression molding.

- Automotive Manufacturing: Component processing, bearing pressing.

- Building Materials: Refractory brick and ceramic product pressing.

| Model | Y32-63 | Y32-100 | Y32-200 | Y32-315 | Y32-400 | Y32-500 | Y32-600A | Y32-630 | Y32-800 | Y32-1000 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal force (kN) | 630 | 1000 | 2000 | 3150 | 4000 | 5000 | 5000 | 6300 | 8000 | 10000 |

| Ejecting force (kN) | 100 | 250 | 400 | 630 | 630 | 1000 | 1000 | 1000 | 1000 | 1250 |

| Return force (kN) | 125 | 320 | 450 | 600 | 600 | 1000 | 1000 | 1000 | 1200 | 1250 |

| Slider stroke (mm) | 500 | 600 | 700 | 800 | 800 | 900 | 900 | 900 | 1000 | 1000 |

| Ejecting stroke (mm) | 160 | 200 | 250 | 300 | 300 | 355 | 355 | 355 | 350 | 350 |

| Max. opening height (mm) | 800 | 900 | 1200 | 1250 | 1250 | 1500 | 1500 | 1500 | 1800 | 1800 |

| Slider speed - Idle down (mm/s) | 100 | 100 | 100 | 100 | 100 | 120 | 80 | 120 | 120 | 120 |

| Slider speed - Work (mm/s) | 9 | 10 | 12 | 12 | 12 | 12 | 12 | 10 | 10 | 10 |

| Slider speed - Return (mm/s) | 50 | 50 | 50 | 60 | 60 | 80 | 70 | 50 | 100 | 100 |

| Ejecting speed - Eject (mm/s) | 50 | 80 | 60 | 60 | 60 | 80 | 80 | 65 | 65 | 65 |

| Ejecting speed - Back (mm/s) | 100 | 160 | 120 | 100 | 100 | 200 | 200 | 200 | 140 | 140 |

| Workbench size - L-R (mm) | 520 | 720 | 900 | 1120 | 1250 | 1400 | 2200 | 1600 | 2200 | 2500 |

| Workbench size - F-B (mm) | 490 | 580 | 900 | 1120 | 1250 | 1400 | 1600 | 1600 | 1600 | 1800 |

| Poles distance - L-R (mm) | 650 | 800 | 1140 | 1140 | 1500 | 1700 | 2620 | 1950 | 2600 | 2900 |

| Poles distance - F-B (mm) | 350 | 430 | 660 | 900 | 1000 | 1120 | 1120 | 1200 | 1200 | 1350 |

| Dimension - L-R (mm) | 900 | 1100 | 1380 | 1160 | 3600 | 3900 | 4700 | 5200 | 6600 | 4650 |

| Dimension - F-B (mm) | 500 | 800 | 900 | 1660 | 2300 | 3600 | 3600 | 4600 | 2600 | 2650 |

| Height on ground (mm) | 2400 | 2600 | 2725 | 4295 | 4500 | 5220 | 5220 | 6000 | 7200 | 6570 |

| Motor power (kW) | 7.5 | 11 | 15 | 22 | 30 | 44 | 45 | 60 | 90 | 90 |

Advantage:

- Four-column structure provides excellent rigidity and anti-eccentric load capacity, ensuring long-term precision operation.

- Available in capacities ranging from tens to thousands of tons to meet diverse industrial needs.

- Equipped with variable pumps or servo hydraulic systems to reduce energy consumption and improve efficiency.

- Supports multiple working modes with adjustable parameters for various process requirements.

- Multi-layer safety protection minimizes equipment failure and operational risks.

- Modular design allows for quick inspection and replacement of key components.