CAMT

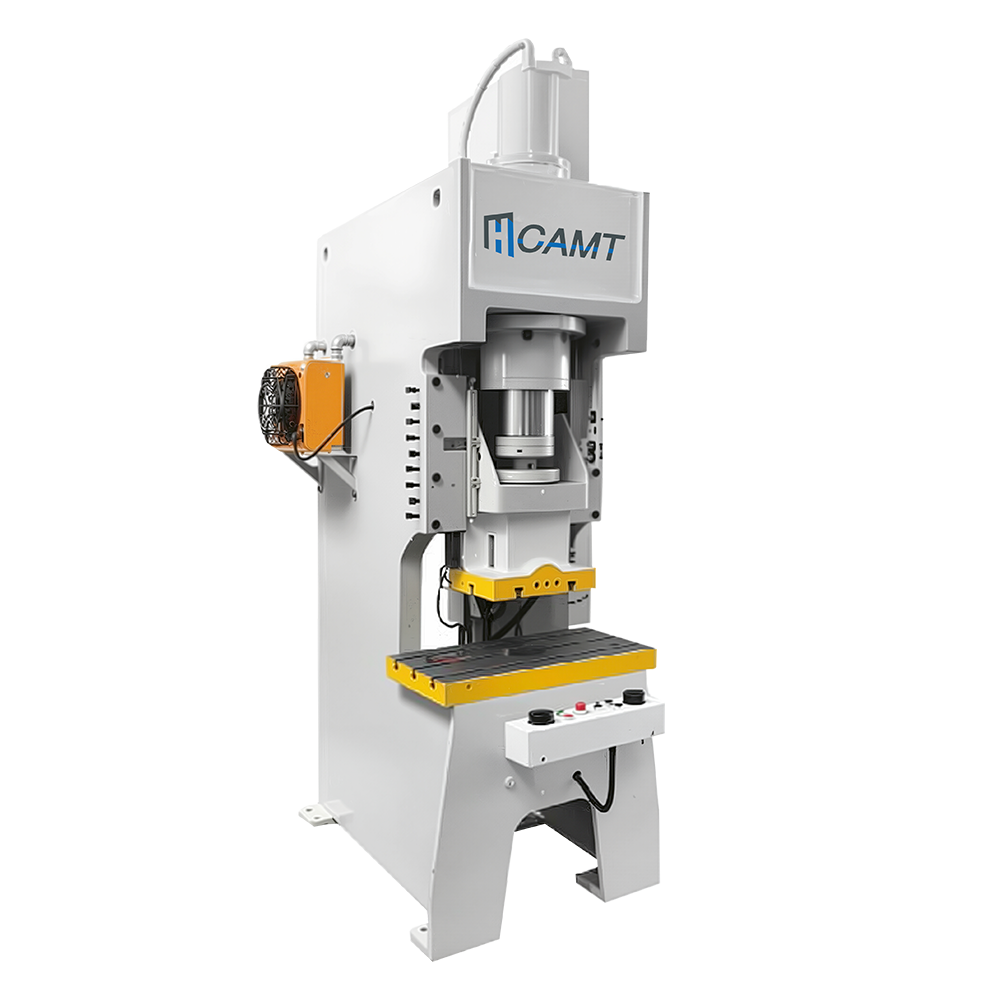

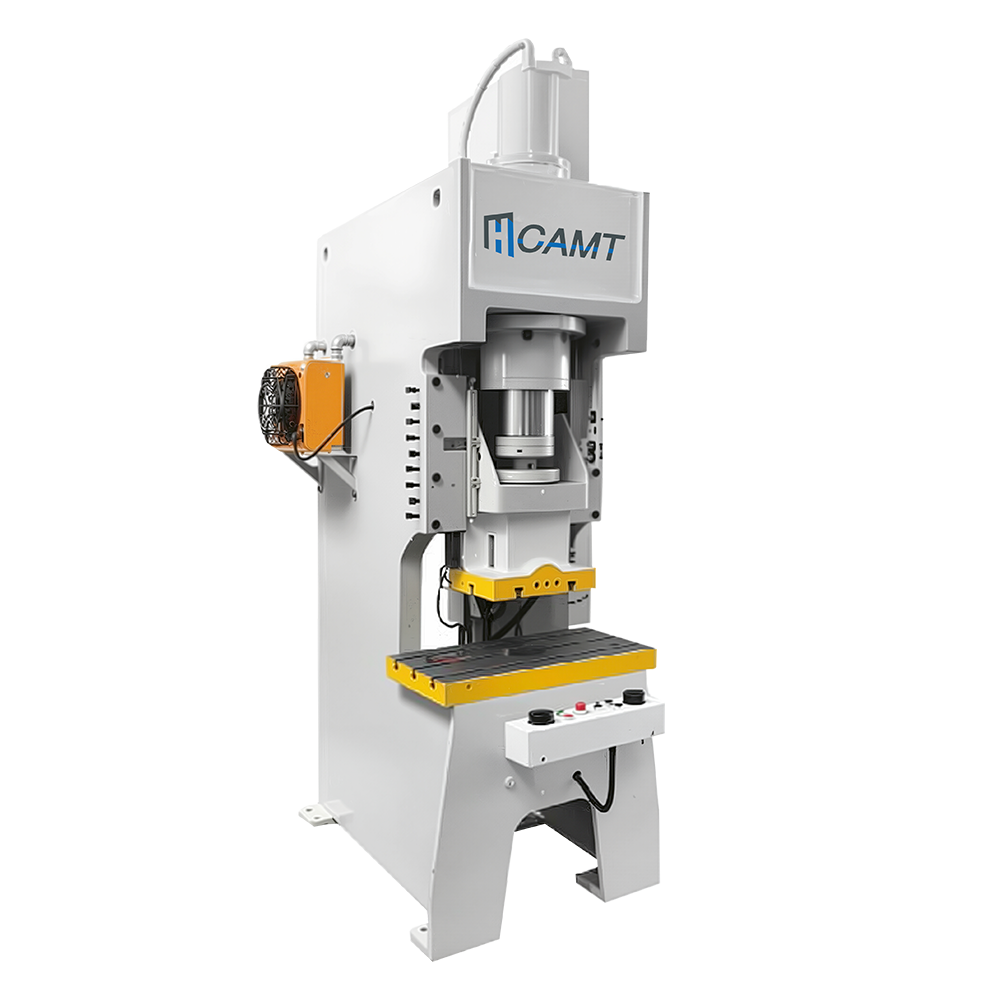

Y27 Single Movement Hydraulic Press Machine

CAMT

Y27 Single Movement Hydraulic Press Machine

CAMT single-column press (C-frame press) is a precision metal forming machine designed based on hydraulic or mechanical transmission principles, featuring an integral C-frame construction as its core characteristic. The machine body is fabricated from high-strength steel plates through welding, optimized by computer finite element analysis and subjected to vibration aging treatment to ensure vertical accuracy of 0.02mm/m under maximum load conditions. Available in two main series – hydraulic type (5-200 tons) and servo-mechanical type (1-60 tons) – based on different drive systems.

The open-front single-column design provides 270° working space combined with an adjustable worktable (optional motorized lifting function), making it particularly suitable for three-dimensional operations on large irregular workpieces. The hydraulic system employs two-way cartridge valve technology paired with Bosch Rexroth pump units from Germany, achieving stepless pressure regulation (±0.5MPa accuracy) and three-stage speed switching (fast approach at 6-12mm/s and adjustable working feed at 0.5-5mm/s). The mechanical version is equipped with Yaskawa servo motors from Japan and precision ball screws, delivering repeat positioning accuracy up to ±0.005mm.

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Space-Saving

High Precision

Energy-Efficient

Flexible Operation

CAMT Powerful Press Solution

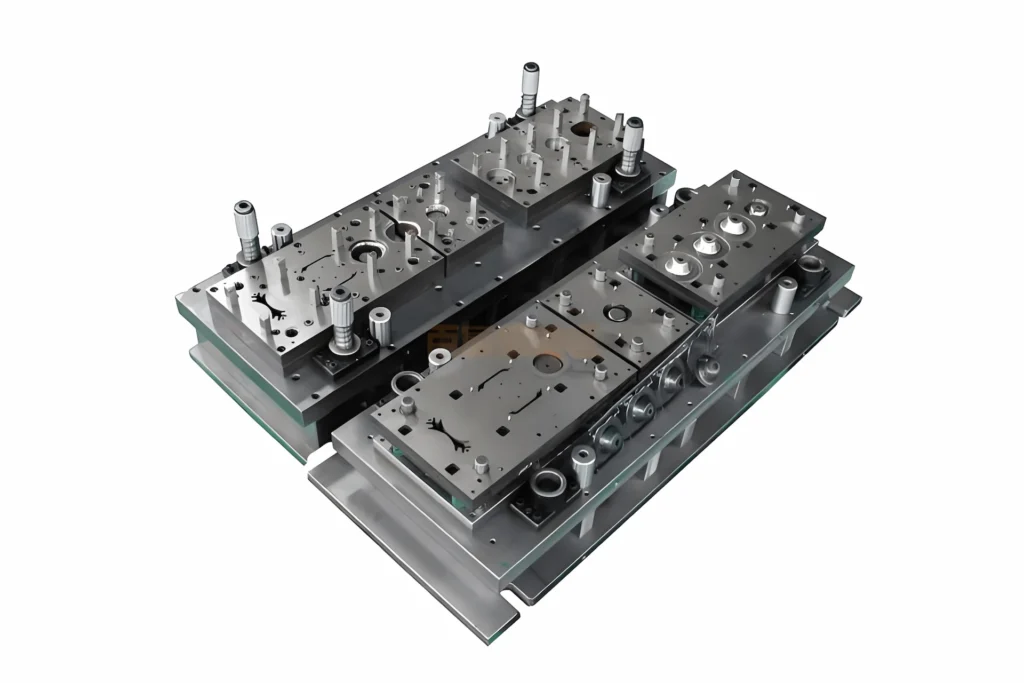

Single-column press (also known as a C-frame press) is a hydraulic or mechanical pressing device featuring a compact, open C-frame structure. Its design allows easy workpiece loading and unloading, making it ideal for stamping, bending, pressing, riveting, and other precision operations on small to medium-sized parts. Widely used in electronics, home appliances, automotive components, and hardware manufacturing, it is particularly suitable for frequent mold changes or small-batch, multi-variety production.

Functional Configuration of Hydraulic Press

Typically includes the following core components

- Equipped with overload protection device, sensitive response, reliable action, can protect molds and machine tools, and can restore machine tools to use in a short time.

- Enclosed gear transmission, oil immersion lubrication, smooth transmission, low noise.

- Adopt combined pneumatic clutch-brake, use imported frictiond materials, long service life.

- Equipped with balancer to effectively ensure working accuracy.

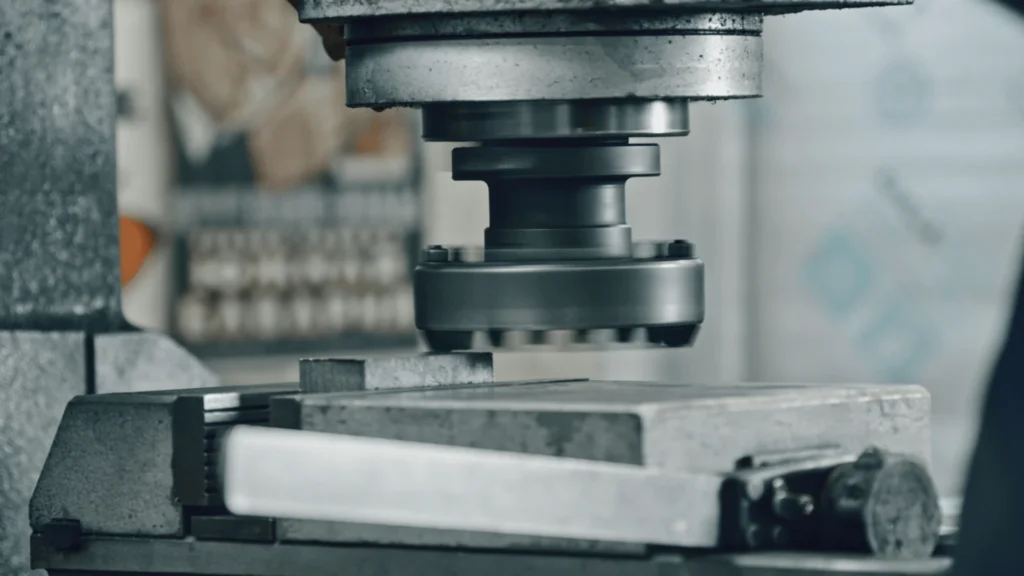

Press Application About Press Machine

Widely used in the following industries

- Stamping: Punching, blanking, and drawing of metal sheets.

- Precision Pressing: Interference fits for bearings, gears, and electronic components.

- Bending: Sheet metal or wire forming.

- Riveting/Embossing: Fastening or logo imprinting.

- Testing: Material compression/elasticity tests.

| Item | Unit | Y27K-25T | Y27KK-40T | Y27K-45T | Y27K-63T | Y27K-80T | Y27K-100T | Y27K-125T | Y27K-160T | Y27K-200T | Y27K-250T | Y27K-315T | Y27K-330T |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal force | KN | 250 | 400 | 450 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | 3300 |

| Stroke adjustment | mm | 10-140 | 10-140 | 10-140 | 10-150 | 10-150 | 10-180 | 10-180 | 10-180 | 10-180 | 10-250 | 10-250 | 10-250 |

| Maximum stroke of slider | mm | 150 | 150 | 150 | 150 | 150 | 200 | 200 | 200 | 200 | 250 | 250 | 250 |

| Maximum opening height | mm | 350 | 360 | 320 | 360 | 420 | 450 | 450 | 450 | 450 | 600 | 620 | 620 |

| Waiting mouth | mm | 230 | 230 | 230 | 230 | 300 | 380 | 380 | 400 | 430 | 450 | 450 | 450 |

| Mould loading height | mm | 210-240 | 210-260 | 210-270 | 180-260 | 180-260 | 230-340 | 230-340 | 220-430 | 220-430 | 380-580 | 380-600 | 380-600 |

| Number of strokes | l/min | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 20-40 | 20-40 | 10-30 | 10-30 | 10-30 |

| Maximum pressure | Mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Quick down speed | mm/s | 110 | 110 | 110 | 120 | 120 | 120 | 120 | 110 | 110 | 110 | 100 | 200 |

| Working speed | mm/s | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 |

| Return speed | mm/s | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 90 | 90 | 90 | 90 | 90 |

| Workbench left and right | mm | 690 | 760 | 810 | 760 | 1000 | 1080 | 1080 | 1080 | 1080 | 1200 | 1300 | 1300 |

| Workbench front and back | mm | 410 | 460 | 460 | 460 | 600 | 600 | 600 | 720 | 800 | 900 | 900 | 900 |

| Blanking hole | mm | 100 | 120 | 150 | 120 | 180 | 180 | 180 | 180 | 200 | 200 | 200 | 200 |

| Height of table above floor | mm | 680 | 820 | 820 | 840 | 860 | 820 | 820 | 900 | 900 | 960 | 960 | 960 |

| Motor power | KW | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 18.5 | 22 | 22 | 30 | 30 |

| Oil pump | Ml/r | 25YCY | 25YCY | 25YCY | 25 | 25 | 25 | 40 | 63YCY | 63YCY4-B | 80YCY4-B | 100YCY4-B | 100YCY4-B |

Advantage:

- Open C-frame allows multi-angle access in tight spaces.

- Customizable worktables for diverse production needs.

- Hydraulic models maintain ±0.5MPa pressure; mechanical versions achieve ±0.01mm repeatability.

- Servo-driven models reduce power consumption by 30%-50% with noise <75dB.

- Meets ISO12100 standards with multi-layer protections.

- Modular design; hydraulic oil change interval up to 2,000 hours.