CAMT

W11-3 Roller Plate Rolling Machine

CAMT

W11 3-Roller Metal Plate Rolling Machine

Mechanical Symmetry HMS3R Series

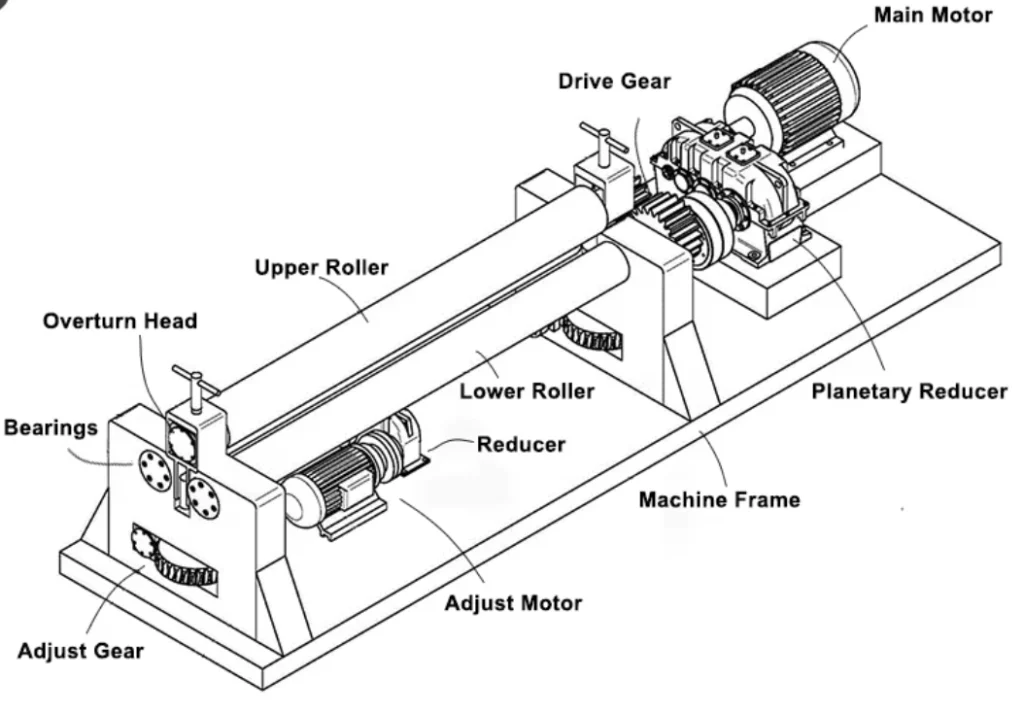

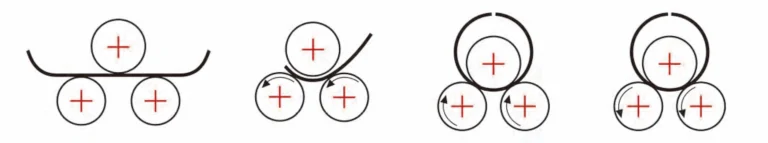

HMS3R Series 3-Roller Plate Rolling Machine, featuring a mechanical drive, utilizes a three-roller symmetrical design. The upper roller moves vertically at the center between the two lower rollers, driven by a system of screws, nuts, worms, and lead screws. The two lower rollers rotate, delivering torque to the plate material through the meshing of the moderator’s output gear with the lower rollers’ gears. For workpiece removal, the upper roller can be disengaged. Optional side wheels can be added to accommodate various metal sheet types. This machine offers a straightforward design, reliable performance, and user-friendly operation, making it a cost-effective solution for plate bending.

CAMT Professional Rolling Machine

Incorporates the Following Attributes and Capabilities

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Corrosion resistance

Premium accessories

High precision rolling

Easy to operate

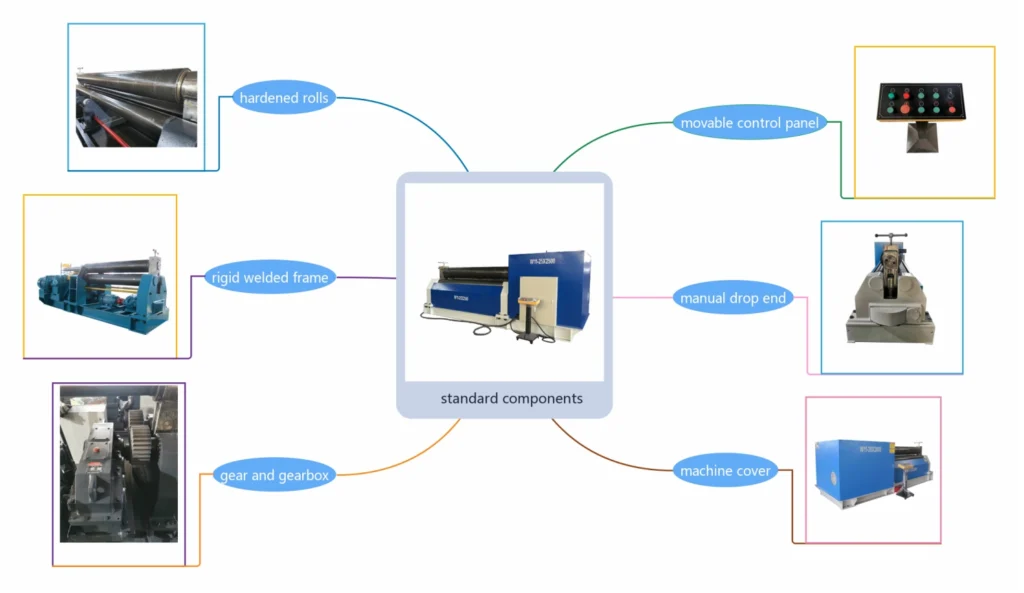

Popular Configuration

- Digital screen display control console

- 42CrMo solid forging roller

- Side motorised rolls

- Segmental inlay roller ring

- Centralised manual lubrication

- Customized Available

Working Roller

Roller is the most important components of the rolling machine, its quality and performance has a direct impact on the service life of the rolling machine and the precision of rolling. Working rollers are made of high-strength high-quality steel 42CrMo material, after forging, roughing, quenching and tempering, HB240 ~ 300, finishing after the intermediate frequency quenching HRC47-58, according to JB/ZG4289-86 roll steel standards. Strictly in roller manufacturing, to ensure its comprehensive mechanical properties.

Safety & Stability

Electrical System of Rolling Machine

Schneider Electric components enhance the machine’s reliable performance. Well-organized wiring and layout significantly minimize malfunctions. The integrated hydraulic valve control module ensures smooth and precise movement of the sliding block. This setup provides excellent protection for both the operator and the machine’s components. A quiet yet robust motor extends the machine’s lifespan and boosts operational stability.

Roller Rotation

Stepper Motor ⇨ Planetary Gearbox ⇨ Working Roll

- Symmetric geometry in the roll movement featured by the 3-roll bending rolls of the series assures optimal traction.

- The upper roll can bend the plate by moving up and down, while the fixed lower roll can realize the plate rolling by turning forward and backward.

- The row self aligning bearing of the upper roll with low resistance plays a strong role in supporting and preventing the sheet from slipping to the maximum extent.

Technical of 3-Roller Plate Rolling Machine

| Model | Max. Bending thickness (mm) | Max. Bending width (mm) | Yield limit (Mpa) | Coiling Speed (m/min) | Top roller diameter (mm) | Bottom roller diameter (mm) | Central distance (mm) | Main power (Kw) |

| W11-4x1500 | 4 | 1500 | 245 | 5 | 150 | 140 | 200 | 4 |

| W11-4x2000 | 4 | 2000 | 245 | 5 | 160 | 150 | 220 | 4 |

| W11-6x1500 | 6 | 1500 | 245 | 5 | 160 | 150 | 220 | 4 |

| W11-6x2000 | 6 | 2000 | 245 | 5 | 170 | 160 | 220 | 5.5 |

| W11-6x2500 | 6 | 2500 | 245 | 5 | 180 | 170 | 250 | 5.5 |

| W11-6x1500 | 8 | 1500 | 245 | 5 | 170 | 160 | 220 | 5.5 |

| W11-6x2000 | 8 | 2000 | 245 | 5 | 180 | 170 | 250 | 5.5 |

| W11-6x2500 | 8 | 2500 | 245 | 5 | 240 | 180 | 280 | 7.5 |

| W11-12x2000 | 12 | 2000 | 245 | 5 | 240 | 180 | 280 | 7.5 |

| W11-12x3000 | 12 | 2500 | 245 | 5 | 280 | 220 | 320 | 11 |

| W11-12x3000 | 12 | 3000 | 245 | 5 | 280 | 220 | 360 | 11 |

| W11-16x2000 | 16 | 2000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-16x2500 | 16 | 2500 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-16x3000 | 16 | 3000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-20x2000 | 20 | 2000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-20x2500 | 20 | 2500 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-25x2000 | 25 | 2000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-25x2500 | 25 | 2500 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-30x2000 | 30 | 2000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-30x2500 | 30 | 2500 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-30x3000 | 30 | 3000 | 245 | 5 | 260 | 220 | 320 | 11 |

| W11-40x2500 | 40 | 2500 | 245 | 5 | 260 | 220 | 320 | 11 |

Advantage:

- Top roller do the movement of elevation in the central position of the two bottom rolls.

- Transmitted by screw nut and worm gear.

- Two bottom rolls are main drive rolls.

- Rotate by the meshing between the output gear of the gear box and the bottom roller and supply the torque for bending plate.

- Compact, easy operate and maintain. Extended shaft for profile bending.