CAMT

W12-4 Roller Plate Rolling Machine

CAMT

W12 4-Roller Metal Plare Rolling Machine

Hrdraulic CNC HMC4R Series

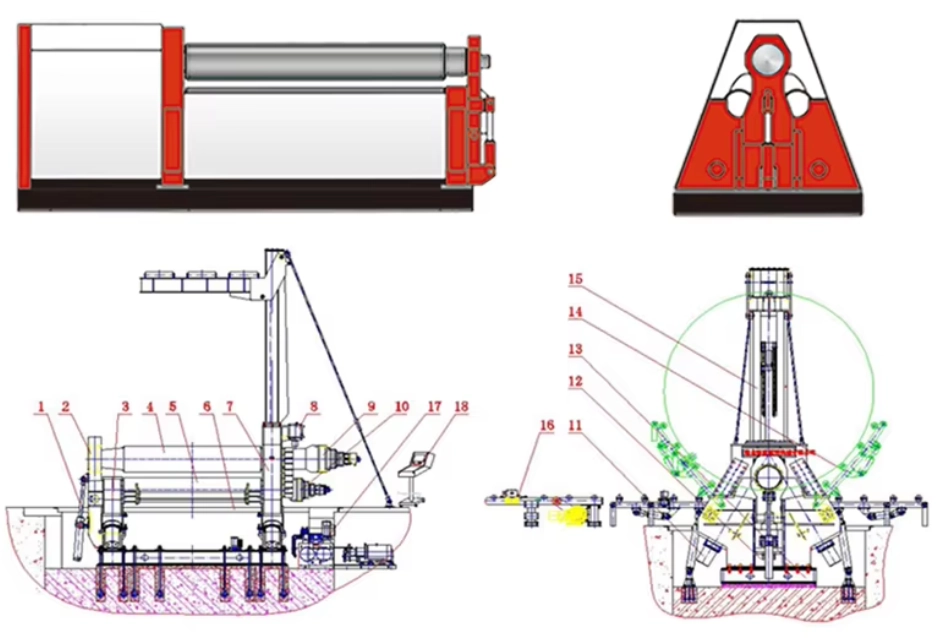

CAMT HMC4R Series 4-Roller Hydraulic CNC Plate Rolling Machine features pre-bending of plate ends and CNC rolling capabilities. It allows one-time feeding of metal plates, completing pre-bending and roll forming without reversing the material. The upper roll serves as the primary drive, while the lower roll and side rolls are powered hydraulically. Computer-controlled lifting ensures automatic leveling, with a synchronization accuracy of ±0.1mm displayed on the screen. The rollover bearing body’s tilting and resetting are hydraulically operated, and a balancing mechanism facilitates easy removal of finished workpieces.

Equipped with a movable standalone control console, the machine offers flexible operation. It includes safety interlocks for enhanced security. With its comprehensive functionality, high precision, and user-friendly design, this machine is an advanced CNC rolling solution. It is ideal for producing circular and arc-shaped components in industries such as energy, transportation, petroleum, chemical, boiler, shipbuilding, hydropower, and metal structures.

CAMT Professional Rolling Machine

Incorporates the Following Attributes and Capabilities

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Corrosion resistance

Premium accessories

High precision rolling

Easy to operate

Popular Configuration

- SIEMENS CNC control system

- Central and side supports

- Automatic loading and unloading systems

- Motorised feeding and squaring tables

- Side motorised rolls

- Provision for hot rolling

- Integrated welding system

- Automatic lubrication system

- Automatic ejector

- Customized Available

Working Roller

Roller is the most important components of the rolling machine, its quality and performance has a direct impact on the service life of the rolling machine and the precision of rolling. Working rollers are made of high-strength high-quality steel 42CrMo material, after forging, roughing, quenching and tempering, HB240 ~ 300, finishing after the intermediate frequency quenching HRC47-58, according to JB/ZG4289-86 roll steel standards. Strictly in roller manufacturing, to ensure its comprehensive mechanical properties.

Safety & Stability

Electrical System of Rolling Machine

Schneider Electric components enhance the machine’s reliable performance. Well-organized wiring and layout significantly minimize malfunctions. The integrated hydraulic valve control module ensures smooth and precise movement of the sliding block. This setup provides excellent protection for both the operator and the machine’s components. A quiet yet robust motor extends the machine’s lifespan and boosts operational stability.

Automatic Rolling and Forming

Contrl System About Rolling Machine

- SIEMENS Smart Line HMI provides an intuitive interface for monitoring machine operations.

- Independent operation panel with automatic rolling program enables single-button control.

- Completes rolling and forming in one cycle without manual intervention.

- Robust storage for hundreds of programs tailored to various rolling specifications.

- Supports manual operation modes for flexibility when required.

Roller Rotation

Hydraulic Motor ⇨ Planetary Gearbox ⇨ Working Roll

Upper roll’s independent hydraulic motor connects directly to the high-power box without intermediate gear transmission, offering the most energy-efficient drive system. Equipped with an instant brake, the hydraulic motor ensures precise stopping of the roll during pre-bending.

Hydraulic System About CAMT Rolling Machine

Each oil circuit is equipped with two relief valves to regulate pressure. The primary relief valve is set to a maximum of 25 MPa to manage the pressure of the main cylinder. The secondary relief valve, set at 16 MPa, controls the pressure for the overturning and balancing cylinders. To ensure precise synchronization of the main oil cylinders at both ends of each moving work roll, high-precision displacement sensors are installed on the left and right racks and tilting frames. The microcomputer control system uses pressure sensors to monitor and adjust the movements of the main oil cylinder pistons, ensuring accuracy at both ends of the work rolls.

Technical of 4-Roller Plate Rolling Machine

| Model | Max. Bending thickness (mm) | Pre-bending thickness (mm) | Max. Working length of rolls (mm) | Yield limit (Mpa) | Top roller diameter (mm) | Bottom roller diameter (mm) | Side roller diameter (mm) | Main power (Kw) |

| W12-4x2000 | 4 | 3.5 | 2050 | 245 | 160 | 140 | 120 | 3 |

| W12-6x2000 | 6 | 5 | 2050 | 245 | 190 | 170 | 150 | 4 |

| W12-8x2000 | 8 | 6.5 | 2050 | 245 | 210 | 190 | 170 | 5.5 |

| W12-10x2000 | 10 | 8 | 2050 | 245 | 230 | 210 | 190 | 7.5 |

| W12-12x2000 | 12 | 10 | 2050 | 245 | 270 | 250 | 210 | 11 |

| W12-16x2000 | 16 | 13 | 2050 | 245 | 300 | 270 | 220 | 11 |

| W12-20x2000 | 20 | 16 | 2050 | 245 | 330 | 300 | 240 | 15 |

| W12-25x2000 | 25 | 20 | 2050 | 245 | 360 | 330 | 250 | 15 |

| W12-30x2000 | 30 | 25 | 2050 | 245 | 390 | 330 | 300 | 18.5 |

| W12-35x2000 | 35 | 28 | 2050 | 245 | 430 | 390 | 330 | 22 |

| W12-40x2000 | 40 | 32 | 2050 | 245 | 460 | 420 | 360 | 30 |

| W12-45x2000 | 45 | 36 | 2050 | 245 | 510 | 460 | 390 | 37 |

| W12-50x2000 | 50 | 40 | 2050 | 245 | 550 | 510 | 420 | 45 |

| W12-4x2500 | 4 | 3.5 | 2550 | 245 | 190 | 170 | 150 | 4 |

| W12-6x2500 | 6 | 5 | 2550 | 245 | 210 | 190 | 170 | 5.5 |

| W12-8x2500 | 8 | 6.5 | 2550 | 245 | 230 | 210 | 190 | 7.5 |

| W12-10x2500 | 10 | 8 | 2550 | 245 | 270 | 250 | 210 | 11 |

| W12-12x2500 | 12 | 10 | 2550 | 245 | 300 | 270 | 220 | 11 |

| W12-16x2500 | 16 | 13 | 2550 | 245 | 330 | 300 | 240 | 11 |

| W12-20x2500 | 20 | 16 | 2550 | 245 | 360 | 330 | 250 | 15 |

| W12-25x2500 | 25 | 20 | 2550 | 245 | 390 | 360 | 300 | 18.5 |

| W12-30x2500 | 30 | 25 | 2550 | 245 | 430 | 390 | 330 | 22 |

| W12-35x2500 | 35 | 28 | 2550 | 245 | 460 | 420 | 390 | 30 |

| W12-40x2500 | 40 | 32 | 2550 | 245 | 510 | 460 | 390 | 37 |

| W12-45x2500 | 45 | 36 | 2550 | 245 | 550 | 510 | 420 | 45 |

| W12-4x3000 | 4 | 3.5 | 3100 | 245 | 210 | 190 | 170 | 5.5 |

| W12-6x3000 | 6 | 5 | 3100 | 245 | 230 | 210 | 190 | 7.5 |

| W12-8x3000 | 8 | 6.5 | 3100 | 245 | 270 | 250 | 210 | 11 |

| W12-10x3000 | 10 | 8 | 3100 | 245 | 300 | 270 | 220 | 11 |

| W12-12x3000 | 12 | 10 | 3100 | 245 | 330 | 300 | 240 | 11 |

| W12-16x3000 | 16 | 13 | 3100 | 245 | 360 | 330 | 250 | 15 |

| W12-20x3000 | 20 | 16 | 3100 | 245 | 390 | 360 | 300 | 18.5 |

| W12-25x3000 | 25 | 20 | 3100 | 245 | 430 | 390 | 330 | 22 |

| W12-30x3000 | 30 | 25 | 3100 | 245 | 460 | 420 | 360 | 30 |

| W12-35x3000 | 35 | 28 | 3100 | 245 | 510 | 460 | 390 | 37 |

| W12-40x3000 | 40 | 32 | 3100 | 245 | 550 | 510 | 420 | 45 |

| W12-50x3000 | 50 | 40 | 3100 | 245 | 610 | 560 | 480 | 55 |

| W12-60x3000 | 60 | 48 | 3100 | 245 | 670 | 620 | 520 | 75 |

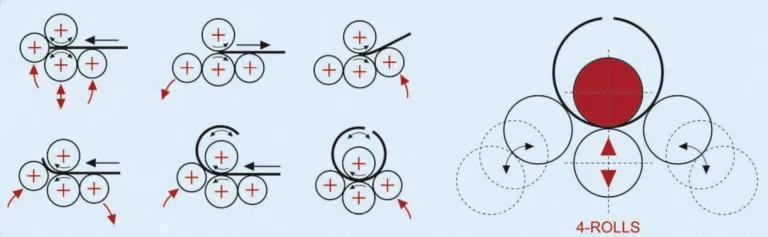

Advantage:

- It's easy to operate, rich shape bend.

- CNC control, digital readout for position of each rollers.

- Full hydraulic drive, High efficiency and energy saving, the drive power is equivalent to the traditional 60%

- productivity is higher 50%-80% than three roller bending machine

- High accuracy and precision circle.

- Aligning the material is convenient and accurate, avoid the wrong side phenomenon.

- The minimum bending diameter of the cylinder can get to 1.1 times the diameter of the top roller, the surplus flat edge smaller than any type of other plate rolling machine.