Adaptability Peak Achievements Excellence in Expectations

Bending Angle Measurement

The Angle Regulation System is a precision-driven angle control technique that computes springback for each distinct bend and adjusts the bending depth via real-time angle manipulation to attain the precise angle.

Angle Measurement System

Automati bending machine angle system is a precision control technology that monitors and adjusts bend angles in real time, calculates and compensates for material springback, ensuring each bend meets exact design specifications, enhancing consistency and efficiency across diverse materials and complex production needs.

Advantage:

- Exceptional Accuracy: Minimal angle deviation (e.g., ±0.5°), meeting rigorous processing standards.

- Reduced Waste: Precise springback compensation minimizes defective parts, saving materials.

- Advanced Automation: Automated detection and adjustment reduce human error.

- High Adaptability: Accommodates various materials and workpieces, ideal for diverse production.

- Enhanced Efficiency: Real-time control shortens processing time, boosting output.

- Improved Safety: Less manual operation lowers workplace risks.

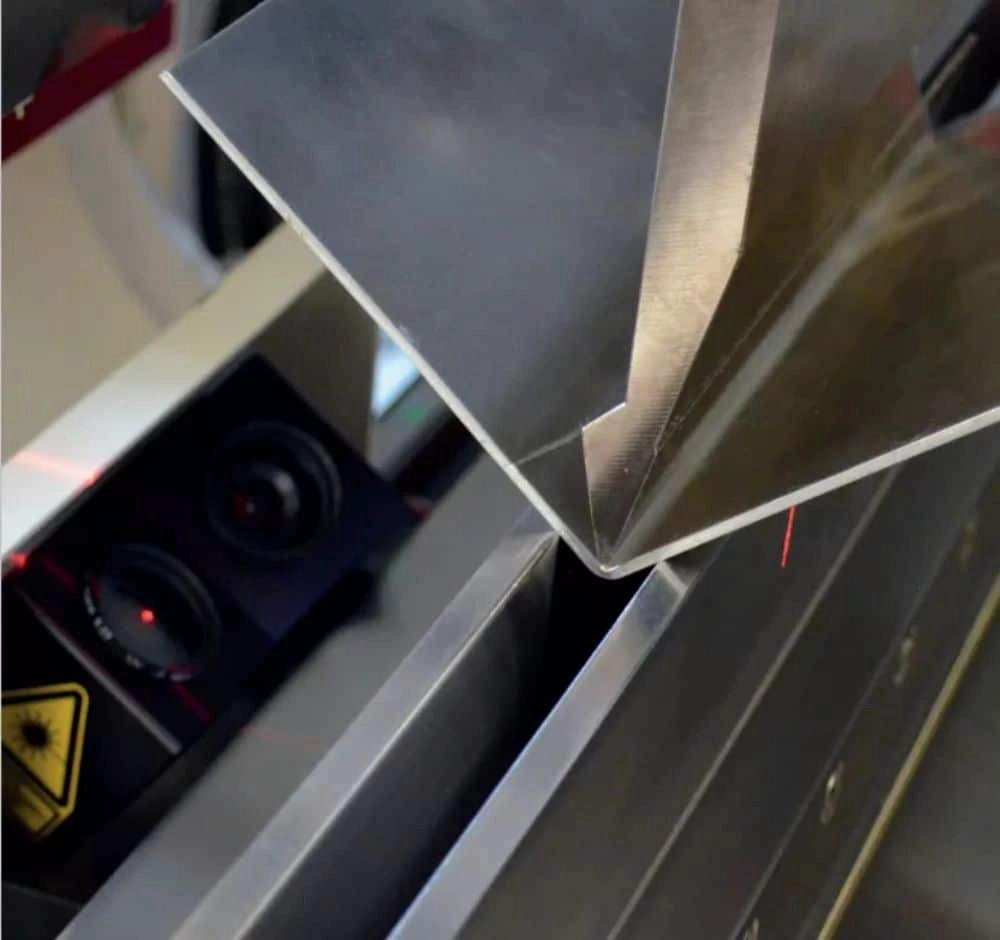

Laser Check Angle Measurement System

Laser check angle system uses laser technology to measure the angle of a workpiece in real-time during the bending process. A laser sensor emits a laser beam onto the surface of the workpiece, and the angle of the reflected light is analyzed to calculate the bending angle. This data is then compared and adjusted by the press brake control system to ensure precise bending angles.

Function:

Press Brake Laser Check Angle Measurement System is to continuously monitor and measure the bending angle of a workpiece in real-time during the bending process. It ensures accurate angles by comparing the measured data with the required specifications and automatically adjusting the press brake parameters when deviations occur, ultimately enhancing production precision and efficiency.

Advantages

- Laser sensor provides highly accurate angle measurements, ensuring the workpieces meet the required specifications.

- Non-contact method, preventing any surface damage to the workpiece that could occur with traditional contact measurements.

- Angle data is displayed in real-time, offering immediate feedback to operators, helping them adjust the production process.

- Automatically detects and calibrates, significantly reducing errors from manual operation and enhancing the automation of the production process