Press Brake Proportional Valve Repair and Maintenance

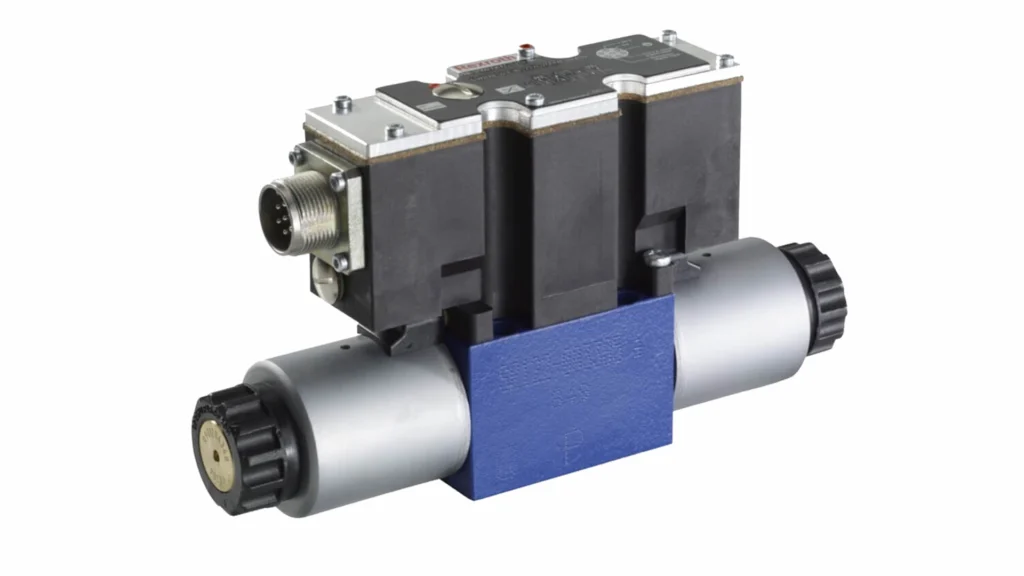

Press brake proportional valves are critical components in hydraulic systems, enabling precise control over fluid flow and pressure based on electronic inputs. These valves enhance accuracy in bending operations, making them indispensable in CNC press brakes and automated manufacturing setups. By converting electrical signals into mechanical movements, they adjust the valve spool to modulate hydraulic output seamlessly. In high-precision environments like metal fabrication, maintaining these valves prevents downtime and boosts productivity. This guide covers their fundamentals, common faults, and proven fixes, drawing from hydraulic engineering best practices.

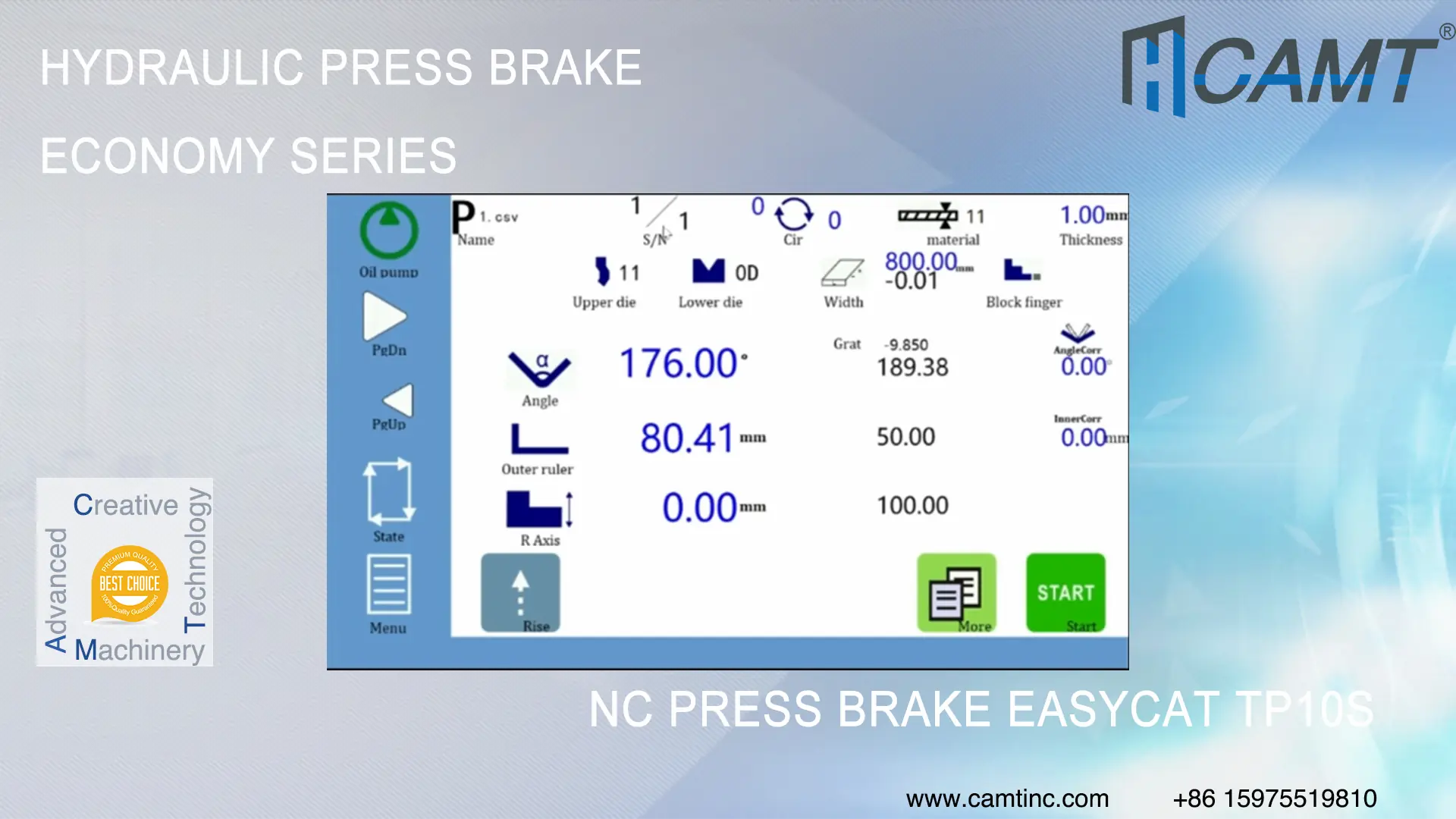

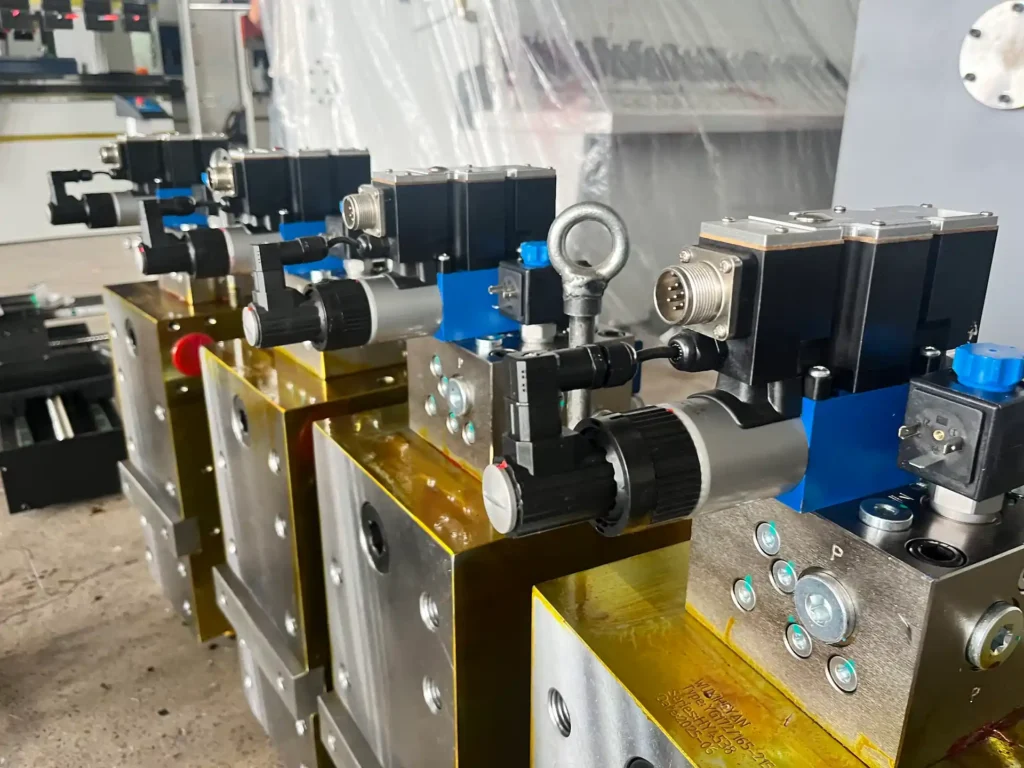

Understanding Press Brake Proportional Valve Definition and Working Principle

A press brake proportional valve is an advanced hydraulic device that regulates fluid flow and pressure proportionally to an input signal, typically from a control system. Unlike traditional on-off valves, it offers variable control for smooth, accurate operations in press brakes.

Core Working Mechanism

The valve operates via an electromagnetic solenoid that shifts the spool position in response to voltage variations. For instance, a 0-10V signal might correspond to 0-100% opening, allowing fine-tuned pressure adjustments in the hydraulic circuit. In press brakes, this ensures synchronized ram movement for precise bending angles.

Key elements include:

Spool and Sleeve Assembly: Controls fluid pathways with micron-level precision.

Feedback Sensors: Monitor position and pressure, feeding data back to the controller for closed-loop accuracy.

Amplifier Electronics: Amplify signals to drive the solenoid effectively.

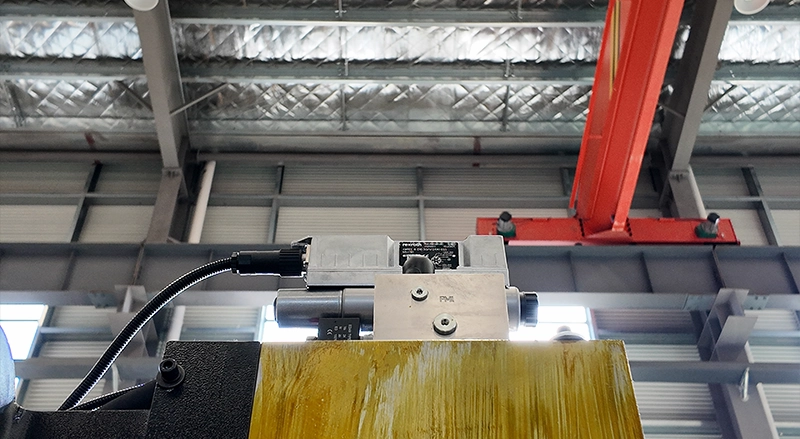

In hydraulic press brakes, these valves integrate with cylinders to manage descent speed and force, reducing errors in sheet metal forming. Regular calibration is essential, as deviations can stem from wear or contamination, impacting overall system efficiency.

Common Issue One: Press Brake Proportional Valve Failure

Valve failure ranks among the top concerns in hydraulic press brakes, often manifesting as no response, erratic operation, or complete shutdown. This disrupts production lines and risks material waste.

Primary Causes

1.Electrical Supply Instability: Fluctuating power can prevent the valve from receiving consistent signals, leading to non-operation.

2.Signal Disruptions: External electromagnetic interference from nearby machinery distorts control inputs.

3.Mechanical Wear: Spool sticking due to debris or corrosion hinders movement.

Effective Troubleshooting and Repair Strategies

Start by verifying power connections and voltage levels using a multimeter—aim for stable readings matching the valve’s specs (e.g., 24V DC). To combat interference, install shielded wiring and ground equipment properly. For mechanical issues, disassemble the valve in a clean environment, inspect for damage, and replace worn seals or spools. Preventive maintenance, such as monthly inspections, can cut failure rates by up to 30%, per hydraulic system reliability studies.

Common Issue Two: Unstable Flow in Press Brake Proportional Valves

Flow instability causes inconsistent hydraulic output, resulting in uneven bends and quality issues in fabricated parts. This problem is prevalent in high-volume operations where precision is paramount.

Key Contributing Factors

1.Improper Calibration: Misaligned settings fail to maintain steady flow under varying loads.

2.Leakage in the System: Worn seals or loose fittings allow fluid escape, disrupting balance.

3.Fluid Property Variations: Changes in temperature or viscosity alter flow dynamics unpredictably.

Solutions for Stabilizing Flow

Recalibrate the valve using manufacturer software or a digital controller, ensuring parameters align with operational demands. Conduct a thorough leak check with pressure gauges, repairing any faults immediately. Incorporate inline flow meters for real-time monitoring and adjust fluid conditions via heaters or coolers. Experts recommend NAS 1638 cleanliness level 7 or better for hydraulic oil to minimize contaminants that exacerbate instability.

Common Issue Three: Slow Response in Press Brake Proportional Valves

Delayed valve response hampers press brake efficiency, especially in fast-cycle applications like automotive part production, leading to longer takt times and reduced throughput.

Underlying Reasons

1.Signal Transmission Delays: Long cabling or poor connections slow down command execution.

2.Solenoid Malfunctions: Faulty coils or amplifiers reduce actuation speed.

3.Blockages in the Line: Accumulated dirt or particulates restrict fluid movement.

Steps to Improve Response Time

Optimize wiring by shortening runs and using high-quality cables to cut latency. Test solenoids with an ohmmeter (normal resistance: 20-100Ω); replace if readings are off. Flush the system periodically with clean fluid and install 10-micron filters to prevent clogs. In advanced setups, upgrading to servo-proportional valves can enhance response by 20-50%, based on engineering benchmarks.

Common Issue Four: Overheating in Press Brake Proportional Valves

Overheating compromises valve integrity, causing seal degradation and potential system failures. It’s a silent threat in continuous-duty environments.

Main Triggers

1.Elevated Fluid Temperatures: Exceeding design limits (typically 50-60°C) generates excess heat.

2.Prolonged High-Load Operation: Constant heavy use builds up thermal stress.

3.Inadequate Cooling: Poor ventilation or missing heat exchangers trap warmth.

Mitigation and Maintenance Techniques

Enhance fluid cooling with dedicated exchangers or fans to keep temperatures in check. Schedule operational breaks to avoid overload, and monitor with thermal sensors for early warnings. Adding external radiators can dissipate heat effectively. Industry data suggests that proper thermal management extends valve lifespan by 40%.

Comprehensive Summary

Beyond the core issues, several other faults plague press brake proportional valves. Here’s a breakdown with targeted fixes:

1.Electromagnetic Coil Failures

Symptoms: No actuation or abnormal heating.

Causes: Irregular resistance or insulation damage.

Fix: Measure with a multimeter (target 20-100Ω); replace coils matching voltage ratings.

2.Spool Sticking (Accounts for 42% of Faults, per 2023 Hydraulic Failure Reports)

Triggers: Contaminants over 5μm or residue buildup.

Remedies: Employ clean fluid (NAS 1638 level 5 or below) and add 10μm filters.

3.Zero Position Drift

Signs: Partial opening without input.

Correction: Manually reset when powered off, then fine-tune bias voltage (±0.5V) via the interface.

4.Pressure Oscillations

Characteristics: Fluctuations exceeding ±10% of set values.

Reasons: Low damping or suboptimal PID settings (start with gain 0.5-1.2).

Solution: Integrate accumulators for stability.

5.Excessive Internal Leakage

Threshold: Over 3% of rated flow in static conditions.

Approach: Swap spool/sleeve pairs, maintaining 5-8μm clearances.

Press brake proportional valves are vital for precision in industrial bending, yet environmental and operational challenges demand vigilant care. By addressing failures, flow inconsistencies, response lags, and overheating through systematic troubleshooting, operators can achieve uptime and efficiency gains. Looking ahead, advancements in smart valves diagnostics promise even greater reliability. For optimal results, consult certified technicians and adhere to OEM guidelines.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.