How to Improve Press Brake Backgauge Accuracy

Optimizing Press Brake Backgauge Accuracy for Precision Sheet Metal Fabrication

In modern manufacturing, sheet metal fabrication is a cornerstone of producing high-quality components for industries ranging from automotive to aerospace. Among the critical processes, bending stands out as a pivotal step that directly influences the dimensional accuracy and aesthetic quality of the final product. However, a persistent challenge plagues manufacturers: even with identical press brake models and materials, parts from different batches often exhibit subtle dimensional variations. In high-precision applications—such as medical equipment or electronics enclosures—these inconsistencies can lead to increased reject rates, higher costs, and compromised market competitiveness.

So, what’s causing these discrepancies, and how can manufacturers enhance press brake backgauge accuracy to achieve consistent results? This article dives deep into the factors affecting backgauge performance, practical solutions to boost precision, and advanced strategies to optimize your press brake operations.

Understanding the Press Brake Backgauge: A Key to Precision

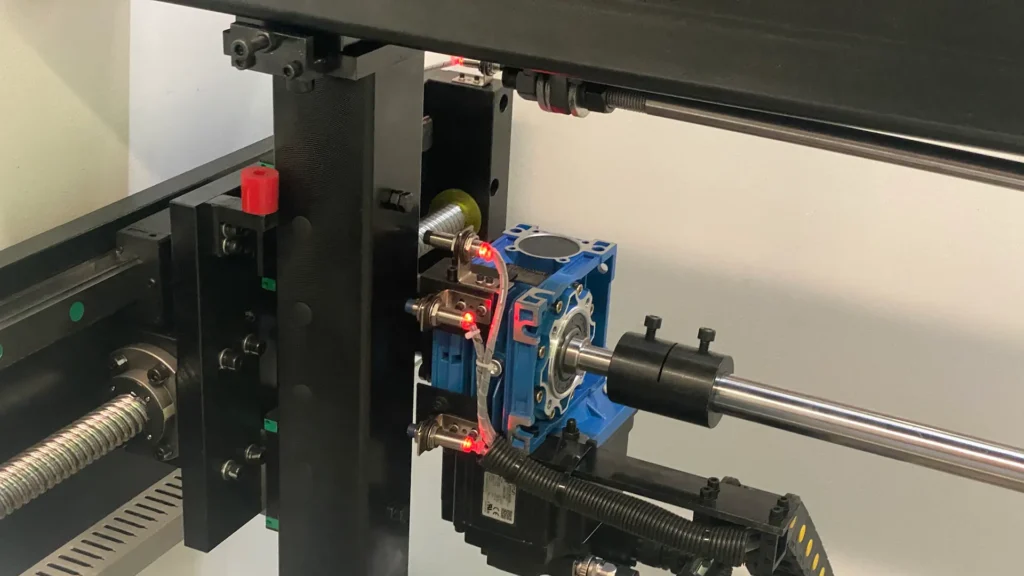

The press brake backgauge is a vital component designed to position workpieces accurately during the bending process. Comprising guide rails, sliders, back fingers, and servo motors, this assembly ensures that sheet metal is placed precisely where it needs to be for each bend. Without a reliable backgauge, even the most advanced press brake can produce inconsistent results, leading to costly rework or scrapped parts.

The backgauge’s primary role is to provide positioning accuracy, ensuring the material aligns perfectly with the bending line. Any deviation here can result in dimensional errors, affecting the part’s fit and function in assemblies. Additionally, the backgauge contributes to stability, preventing material shifts or vibrations during bending, and offers adjustability to accommodate various sheet sizes and thicknesses. Finally, durability is crucial, as the system must withstand repeated stress and wear while maintaining precision over time.

Why Positioning Accuracy Matters

Positioning accuracy is the foundation of a high-performing backgauge. It ensures that the sheet metal reaches the exact predetermined position for every bend. In high-speed automated setups—common in large-scale production—any lag or misalignment in the backgauge can cascade into significant batch inconsistencies. For example, in industries requiring tolerances as tight as ±0.1 mm, such as aerospace or precision engineering, even a slight offset can render parts unusable.

To address this, advanced backgauges incorporate dual servo motors for finer control and automated adjustments. Systems like CAMT’s S-Series press brakes use HIWIN linear guide rails and ball screws, paired with CNC controls, to achieve exceptional precision. These components are meticulously installed to maximize stability and accuracy, ensuring consistent performance even under high workloads. Upgrading to a 6+1 axis configuration further enhances flexibility, allowing the backgauge to handle complex bending sequences with ease.

Minimizing Human Error Through Automation

Human error is a significant factor in bending inconsistencies, particularly in shops relying on manual or semi-automated setups. Skilled operators may position materials based on experience, but even a millimeter’s misjudgment can lead to defects. A robust backgauge mitigates this by providing consistent, repeatable positioning, reducing reliance on operator skill.

In fully automated environments, where robotic arms or follow-up carts handle material feeding, the backgauge’s role becomes even more critical. It must synchronize perfectly with these systems to maintain cycle times and quality. For smaller operations without the budget for full automation, a well-designed backgauge still offers significant benefits by streamlining setup and reducing manual adjustments.

For instance, CAMT’s backgauges allow for rapid reprogramming via CNC interfaces, enabling operators to switch between jobs quickly. This adaptability is crucial for job shops handling custom orders with varying material specifications.

Ensuring Stability for Consistent Bend

Stability is another cornerstone of press brake accuracy. During bending, the workpiece must remain stationary to avoid vibrations or slippage that could skew bend angles or lengths. Backgauge fingers, typically made from hardened steel or reinforced alloys, must provide robust support to withstand the forces involved.

Instability often manifests as chatter marks or uneven edges, which are unacceptable in precision applications. Regular maintenance, such as checking finger alignment and tightening connections, helps maintain stability. CAMT’s innovative design places guide rails on the beam’s sides rather than the top, allowing the broader beam to absorb impacts. This reduces wear on the rails, enhances long-term stability, and minimizes deviations caused by repeated collisions.

The Role of Adjustability in Versatile Production

A high-quality backgauge excels in its ability to adapt to different materials and job requirements. Sheet metal comes in various gauges, widths, and compositions, and the backgauge must adjust quickly and accurately to accommodate these variations. Manual adjustments are time-consuming and prone to errors, so automated systems are a game-changer.

CNC-controlled backgauges, like those in CAMT’s S-Series, allow operators to input bending parameters and let the system handle positioning automatically. Sensors can detect material edges in real-time, making micro-adjustments to ensure perfect alignment. This is particularly valuable for high-mix, low-volume production, where frequent job changes are common.

Durability: The Key to Long-Term Precision

Press brakes operate in demanding environments, subjecting the backgauge to constant stress, abrasion, and impacts. A durable system, built with high-quality materials like precision-ground rails and sealed bearings, is essential to maintain press brake accuracy over thousands of cycles.

Without durability, wear can lead to gradual drifts in positioning, increasing error rates. Investing in a robust backgauge from a reputable manufacturer like CAMT ensures long-term reliability. Their S-Series, for instance, uses a dual-rail design that enhances stability and resists deformation, even when bending thick plates.

Case Study: A metal fabrication shop reported a 30% reduction in maintenance downtime after switching to CAMT’s S-Series, thanks to its durable backgauge design.

Common Backgauge Issues and How to Fix Them

Backgauge precision issues often manifest as:

- Dimensional deviations between bends and design specs.

- Inconsistent part sizes across batches.

- Jittering or stalling during operation.

These problems can erode product quality, but they’re addressable through targeted strategies:

1.Routine Maintenance: Conduct daily checks for wear on components like fingers, rails, and screws. Replace damaged parts promptly to prevent cascading errors.

2.Mechanical Adjustments: Inspect guide rails, lead screws, and nuts for looseness or wear. Tighten connections and realign components as needed to maintain stability.

3.Electrical Calibration: Verify sensor and motor performance to ensure accurate position feedback. Faulty sensors or motors can cause erratic movements, so calibrate them quarterly.

4.Ram Alignment: Ensure the press brake’s ram maintains straightness and proper clearance with the frame’s guides. Misalignment here amplifies backgauge errors.

5.Mold Precision: Check upper and lower dies for wear, deformation, or misalignment. Use precision tools to verify mold accuracy, as even minor deviations can skew results.

6.Software Optimization: Leverage data analytics to refine control algorithms. Machines with machine learning capabilities, configurable at purchase, can minimize discrepancies over time.

7.Operator Training: Regular training reduces errors from improper setup or operation. Teach staff to follow standardized procedures and use CNC interfaces effectively.

Spotlight on CAMT’s S-Series: A Benchmark in Backgauge Design

CAMT’s single-servo hybrid CNC press brake (S-Series) exemplifies cutting-edge backgauge technology. Its 6+1 axis configuration uses a dual-rail setup for smoother, more stable operation compared to traditional single-rail designs. By mounting rails on the beam’s sides, CAMT ensures the beam absorbs impacts, reducing wear and maintaining precision over time.

This design contrasts with conventional setups, where rails mounted atop the beam are prone to damage from vibrations and collisions. The S-Series also features a servo-driven hydraulic pump, a mechanical compensation table, and three control system options, making it ideal for heavy-duty applications like thick-plate bending. Customers report efficiency gains of up to 3x over traditional machines, thanks to the extended slider stroke and robust backgauge.

Customer Feedback: A Midwest fabricator noted that the S-Series’ backgauge reduced setup times by 40%, allowing them to take on more custom orders without sacrificing quality.

Comprehensive Strategies for Sustained Press Brake Accuracy

To maximize press brake backgauge accuracy, manufacturers must adopt a holistic approach:

- Invest in Quality Equipment: Choose systems with proven components, like CAMT’s HIWIN rails and dual-servo motors, to ensure precision from day one.

- Implement Proactive Maintenance: Schedule regular inspections and calibrations to catch issues early. Use a checklist to cover mechanical, electrical, and mold-related components.

- Leverage Data-Driven Insights: Analyze production data to identify patterns in deviations and refine software settings accordingly.

- Train Your Team: Conduct quarterly training sessions to enhance operator skills and reduce human error.

- Upgrade Strategically: Opt for modular backgauges that support future enhancements, such as additional axes or automation integrations.

By combining these strategies, manufacturers can turn backgauge challenges into opportunities for operational excellence. Whether producing thin-gauge electronics components or heavy-duty structural parts, a well-optimized backgauge ensures every bend meets stringent quality standards.

Conclusion

The press brake backgauge is more than a positioning tool; it’s the linchpin of bending precision. By prioritizing accuracy, stability, adjustability, and durability, manufacturers can achieve consistent results, reduce waste, and enhance competitiveness. Systems like CAMT’s S-Series set the standard with innovative designs and robust performance, but ongoing maintenance and operator training are equally critical.

Ready to take your sheet metal fabrication to the next level? Invest in a high-quality backgauge system, implement rigorous maintenance protocols, and empower your team with the skills to excel. The result? Flawless bends, satisfied customers, and a stronger bottom line.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.