Differences Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines

Navigating the Choice Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines

When investing in a laser cutting machine, businesses often face a challenging decision. Without clear standards or comprehensive data, many default to price as the sole deciding factor. In today’s saturated and diverse market, where countless models and brands compete, this approach is increasingly common. However, choosing a laser cutting machine based purely on cost can overlook critical performance factors, potentially leading to equipment that doesn’t align with your operational needs.

To guide you through this complex decision, this article explores the essential considerations for selecting between a fiber laser cutting machine and a CO2 laser cutting machine. While both technologies excel in specific applications, their differences in performance, cost, and maintenance make them suited to distinct scenarios. Importantly, there’s no universal solution—each company’s requirements, from material types to production volume, dictate the best choice. By understanding the nuances of these machines, you can make a decision that maximizes efficiency and long-term value.

Our goal is to provide a detailed, practical comparison of fiber laser cutting machines and CO2 laser cutting machines, empowering you to align your purchase with your business objectives. We’ll cover key selection factors, industry trends, and actionable purchasing tips, ensuring you have the insights needed to choose wisely.

Key Factors in Choosing Between Fiber and CO2 Laser Cutting Machines

Selecting the right laser cutting machine involves evaluating several critical factors, from the type of laser to the equipment’s design and future scalability. Below, we break down the most important considerations to help you determine whether a fiber laser cutting machine or a CO2 laser cutting machine is the better fit for your needs.

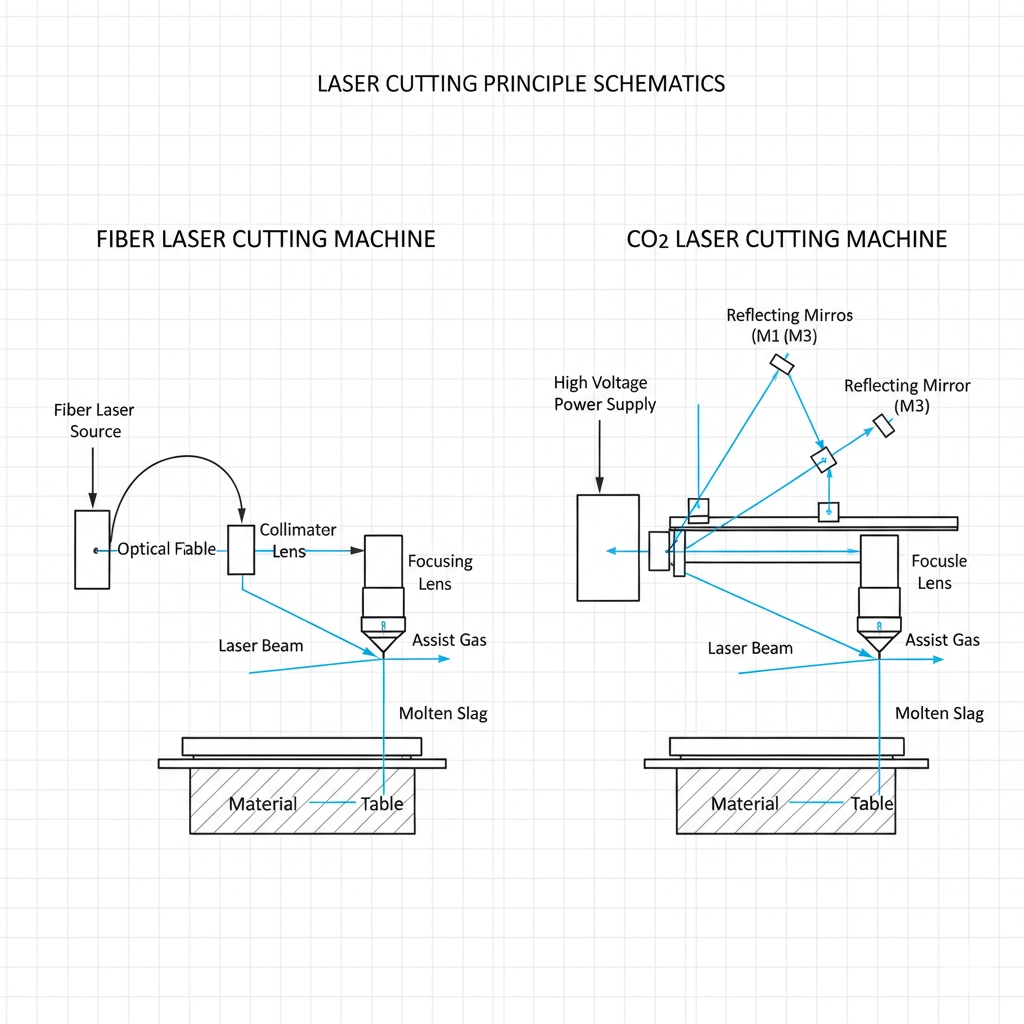

Laser Type: Fiber Laser Cutting Machine vs. CO2 Laser Cutting Machine

The cornerstone of your decision lies in choosing between a fiber laser cutting machine and a CO2 laser cutting machine. This choice hinges on your primary applications, material types, and production goals.

CO2 Laser Cutting Machines: Strengths and Applications

CO2 laser cutting machines use a gas mixture (primarily CO2, with oxygen, helium, and xenon as auxiliaries) to generate a laser beam with a wavelength of 10.64μm. This wavelength is readily absorbed by non-metallic materials, making CO2 lasers ideal for cutting wood, acrylic, glass, leather, and plastics. They also excel in processing thicker materials, delivering superior cut quality with smooth edges, especially for applications like signage or furniture manufacturing.

For example, a CO2 laser cutting machine can effortlessly slice through 20mm acrylic sheets with minimal post-processing, a task where precision and finish are critical. However, their efficiency drops when cutting highly reflective metals like copper or brass, as the longer wavelength struggles with these materials.

Fiber Laser Cutting Machines: Advantages and Capabilities

In contrast, fiber laser cutting machines employ solid-state diode-pumped lasers, transmitted through flexible fiber optic cables, with a wavelength of 1.064μm—ten times shorter than CO2 lasers. This shorter wavelength, combined with a smaller focal point, makes fiber laser cutting machines exceptionally effective for cutting metals, including stainless steel, aluminum, and titanium. Their ability to focus intense energy on a small area results in faster cutting speeds and higher precision, particularly for thin to medium-thickness materials.

Recent advancements have also expanded the capabilities of fiber laser cutting machines to handle thicker metals, bridging the gap with CO2 lasers. For instance, modern fiber laser cutting machines can cut up to 25mm steel plates with clean edges, rivaling CO2 performance while maintaining higher speeds. Additionally, fiber laser cutting machines offer significant advantages:

Faster Cutting Speeds: Up to three times faster than CO2 lasers for thin metals, ideal for high-volume production.

Lower Energy Consumption: With a photoelectric conversion rate of 25%-30% (compared to 8%-10% for CO2), they’re more energy-efficient.

Reduced Maintenance Costs: Fiber lasers have fewer moving parts and durable components, minimizing downtime and repair expenses.

For a metal fabrication shop producing automotive parts, a fiber laser cutting machine could cut 2mm steel sheets in half the time of a CO2 laser cutting machine, boosting throughput and profitability.

Cutting Head Configuration: Enhancing Productivity

Another critical factor is the number and type of cutting heads. Equipping a laser cutting machine with dual cutting heads can significantly increase productivity, especially for high-volume operations. For example, dual heads allow simultaneous cutting of multiple parts, reducing cycle times in industries like aerospace or electronics manufacturing.

Additionally, the type of cutting head matters. Standard straight cutting heads are versatile for most applications, but bevel cutting systems—used for creating angled edges—are essential for industries like shipbuilding or structural steel fabrication. However, not all manufacturers offer bevel cutting options, so verify this feature when evaluating models. Choosing between a fiber laser cutting machine with advanced cutting head options and a CO2 laser cutting machine with standard configurations depends on your specific workflow and output requirements.

Industry Trends in Laser Cutting Technology

The laser cutting industry is evolving rapidly, with two dominant trends shaping equipment development:

Higher Speeds and Power: Manufacturers are pushing for fiber laser cutting machines and CO2 laser cutting machines with greater power (up to 20kW or more) and faster cutting speeds. These advancements cater to cutting centers handling diverse orders with low part repetition, such as contract manufacturers serving multiple clients.

Automation and 24/7 Operation: Automated material loading and unloading systems are becoming standard, enabling round-the-clock production. This is particularly beneficial for companies with high-volume, repetitive parts, such as those in automotive or appliance manufacturing. Fiber laser cutting machines, with their lower maintenance needs, are especially well-suited for automated setups, ensuring consistent output with minimal human intervention.

These trends highlight the importance of aligning your equipment choice with your production scale and operational model. A fiber laser cutting machine with automation features might be ideal for a factory running continuous shifts, while a CO2 laser cutting machine could suffice for a smaller workshop focused on non-metal materials.

Core Differences Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines

To provide a clearer comparison, let’s examine the five primary differences between fiber laser cutting machines and CO2 laser cutting machines:

1. Laser Source and Beam Delivery

CO2 Laser Cutting Machine: Generates a laser beam using a CO2 gas-filled tube, with the beam directed through mirrors and lenses to the cutting head. This complex optical system requires precise alignment and regular maintenance.

Fiber Laser Cutting Machine: Uses diode-pumped solid-state lasers, with the beam transmitted via flexible fiber optic cables. This simplifies the system, enhances beam consistency, and reduces maintenance needs.

2. Material Suitability

CO2 Laser Cutting Machine: Excels at cutting non-metals (e.g., wood, acrylic, textiles) due to its longer wavelength, which is absorbed well by organic materials. It’s less effective for reflective metals.

Fiber Laser Cutting Machine: Optimized for metals, including highly reflective ones like copper and brass. Its shorter wavelength ensures precise cuts on thin to medium-thickness metals, with improving capabilities for thicker materials.

3. Production Costs

CO2 Laser Cutting Machine: Consumes significant amounts of assist gases (CO2, O2, He, Xe), contributing to higher operating costs. Its lower photoelectric conversion rate (8%-10%) also increases energy expenses.

Fiber Laser Cutting Machine: Requires fewer consumables and boasts a higher conversion rate (25%-30%), making it more cost-effective and energy-efficient over time.

4. Maintenance Expenses

CO2 Laser Cutting Machine: Features delicate components like mirrors and lenses, which are prone to wear and costly to replace. Regular maintenance is essential to prevent downtime.

Fiber Laser Cutting Machine: Virtually maintenance-free, with durable components that require infrequent replacement, reducing long-term costs.

5. Cutting Efficiency

CO2 Laser Cutting Machine: Its broader beam dispersion limits speed, especially for large-scale metal cutting. It’s slower when processing thick plates.

Fiber Laser Cutting Machine: Offers high beam density and intensity, enabling faster cuts and greater efficiency, particularly for metals. This makes it ideal for high-throughput environments.

For example, a fiber laser cutting machine cutting 1mm stainless steel can achieve speeds of 20-30 meters per minute, while a CO2 laser cutting machine might manage only 5-10 meters per minute for the same task. This gap widens in large-scale production, where fiber laser cutting machines shine.

Practical Tips for Selecting the Right Laser Cutting Machine

To ensure your investment delivers value, consider these actionable tips when choosing between a fiber laser cutting machine and a CO2 laser cutting machine:

Define Your Equipment’s Purpose

Advanced features, such as high-power lasers or automation, are only valuable if they align with your needs. Before purchasing, clarify your goals:

What materials will you cut most frequently? (Metals favor fiber laser cutting machines; non-metals suit CO2 laser cutting machines.)

What are your production volumes and turnaround times? (High-volume shops benefit from fiber laser cutting machines’ speed.)

Do you need versatility or specialization? (CO2 lasers offer broader material compatibility, while fiber lasers excel in precision metalwork.)

For instance, a custom jewelry manufacturer might prioritize a fiber laser cutting machine for its ability to create intricate metal patterns, while a signage company would lean toward a CO2 laser cutting machine for its non-metal versatility.

Prioritize Long-Term Operational and Maintenance Costs

A laser cutting machine is a long-term investment, and its ongoing costs can significantly impact profitability. Fiber laser cutting machines generally offer lower operational expenses due to their energy efficiency and minimal maintenance. In contrast, CO2 laser cutting machines may incur higher costs for gas refills and optical component replacements.

Reliable after-sales support is equally critical. Downtime from equipment failure can disrupt production and erode profits. When evaluating suppliers, inquire about:

Warranty terms and service response times.

Availability of spare parts and local technical support.

Training programs to ensure your team can operate and maintain the machine effectively.

For example, a fiber laser cutting machine with a robust service plan might cost more upfront but save thousands in maintenance over a decade compared to a CO2 laser cutting machine with frequent lens replacements.

Evaluate Scalability and Future Needs

As your business grows, your equipment must keep pace. Consider whether the machine can handle increased production demands or new material types. Fiber laser cutting machines are often more future-proof due to their compatibility with automation and improving thick-material capabilities. However, if your focus remains on non-metal applications, a CO2 laser cutting machine may remain relevant longer.

Conclusion: Making an Informed Decision

Choosing between a fiber laser cutting machine and a CO2 laser cutting machine requires a careful balance of immediate needs and long-term goals. Fiber laser cutting machines are increasingly popular for their speed, efficiency, and low maintenance, making them ideal for metal-focused, high-volume operations. Conversely, CO2 laser cutting machines remain a go-to choice for non-metal materials and applications requiring superior cut quality on thicker substrates.

By defining your material requirements, assessing production demands, and factoring in operational costs, you can select a machine that drives efficiency and profitability. Always prioritize reputable suppliers with strong after-sales support to ensure your investment delivers lasting value. Whether you choose the precision of a fiber laser cutting machine or the versatility of a CO2 laser cutting machine, aligning your choice with your business’s unique needs is the key to success.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.