Technical Advantages of Electro-Hydraulic Servo CNC Press Brake

The electro-hydraulic servo CNC press brake represents a significant advancement in sheet metal fabrication technology, integrating hydraulic power with servo-electric control to achieve enhanced performance metrics. This machine, often referred to interchangeably as a hybrid press brake due to variations in manufacturer nomenclature, addresses key limitations of traditional hydraulic systems while incorporating the precision of servo mechanisms. Manufacturers adopt distinct naming conventions to differentiate their products in a competitive market; for instance, classifications based on servo motor count—such as single-servo or double-servo configurations—highlight operational capabilities rather than fundamental differences in design. This article examines the technical advantages of the electro-hydraulic servo CNC press brake, drawing on empirical data, comparative analyses, and practical applications to underscore its superiority in modern manufacturing environments.

Fundamental Principles of Operation

To appreciate the technical merits of the electro-hydraulic servo CNC press brake, it is essential to understand its operational framework in contrast to traditional hydraulic systems. Conventional hydraulic press brakes rely on asynchronous motors to drive hydraulic pumps, which in turn regulate fluid flow to cylinders for ram movement. This open-loop approach, while robust for high-tonnage applications, is susceptible to inconsistencies arising from fluid viscosity changes, thermal expansion, and pressure fluctuations. Such variables can lead to deviations in bend angles and positioning, often exceeding ±0.5 degrees and ±0.1 mm, respectively, over extended production runs.

In contrast, the electro-hydraulic servo CNC press brake employs servo motors as the primary drive mechanism, replacing asynchronous units. The servo motor interfaces with a CNC controller that processes feedback from linear encoders—typically grating scales positioned on both main cylinders. This setup facilitates a closed-loop control system, where real-time data on position and velocity inform proportional adjustments to hydraulic flow via servo valves. The result is synchronized ram motion, with the slider achieving precise descent, hold, and retraction phases. For double-servo models, this synchronization is amplified, enabling handling of workloads up to 500 tons with minimal drift.

Technically, the system’s proportional electro-hydraulic servo valves regulate flow based on CNC commands, ensuring that cylinder pressures align exactly with required force profiles. This integration reduces latency in response times, often to milliseconds, compared to the slower valve actuation in traditional hydraulics. Moreover, the closed-loop feedback loop, constituted by grating scales, provides accuracy enhancements; studies indicate repeatability within ±0.01 mm, a tenfold improvement over conventional systems. Such precision is critical in industries like aerospace, where component tolerances directly impact assembly integrity.

From a mechanical perspective, the machine’s design incorporates dual hydraulic cylinders for upper transmission, supplemented by mechanical stops for added stability. Backgauge adjustments are electrically driven with manual fine-tuning options, displayed digitally for operator convenience. This hybrid architecture not only mitigates the energy inefficiencies of constant hydraulic pumping but also enhances overall system responsiveness. In practical terms, the servo-driven pump operates only during active cycles, contrasting with the perpetual operation of traditional pumps, which contributes to excessive heat generation and component wear.

Historical context further illuminates these advancements. The evolution from purely mechanical press brakes in the mid-20th century to hydraulic dominance in the 1970s set the stage for servo integration in the 1990s. Early servo applications focused on electric press brakes for low-tonnage tasks, but the electro-hydraulic variant emerged to bridge the gap for heavier duties, combining hydraulic force with servo precision. Today, standards like those from the Fabricators & Manufacturers Association emphasize closed-loop systems for compliance with ISO tolerances, underscoring the shift toward hybrid technologies.

Precision and Accuracy Enhancements

ne of the paramount advantages of the electro-hydraulic servo CNC press brake lies in its superior precision and accuracy, which surpass those of traditional hydraulic counterparts across multiple dimensions. Precision in sheet metal bending is quantified by metrics such as bend angle consistency, ram repeatability, and parallelism across the bed length. Traditional hydraulic systems, reliant on open-loop pressure control, exhibit variability; for instance, bend angles may fluctuate by ±0.5 degrees due to hydraulic fluid dynamics, leading to rework rates of up to 15% in high-volume production.

The electro-hydraulic servo model counters this through its closed-loop mechanism. Linear encoders provide feedback at rates exceeding 1,000 samples per second, allowing the CNC controller to execute real-time corrections. Empirical data from machine tool evaluations reveal that servo-hybrid systems achieve bend angle accuracy of ±0.2 degrees and ram repeatability of ±0.01 mm, representing a 60% improvement in consistency. In specialized configurations, accuracy reaches 1 micron, compared to 10.16 microns in hydraulic setups. This level of control is facilitated by proportional valves that modulate flow precisely, minimizing overshoot and ensuring uniform pressure distribution.

Comparative analyses highlight these gains. A 2023 study by the International Journal of Machine Tools and Manufacture compared hybrid and traditional brakes on 6mm aluminum sheets, finding that hybrids maintained parallelism within ±0.1 mm over 3-meter beds, versus ±0.3 mm for hydraulics. Such disparities translate to practical benefits: reduced scrap, fewer post-bend adjustments, and enhanced downstream assembly efficiency. For example, in automotive chassis production, where tolerances are critical for structural integrity, hybrids reduce defect rates by 25-30%.

Multi-angle evaluations further reinforce this superiority. From a kinematic standpoint, the servo motor’s torque control enables variable speed profiles—rapid approach, slow bending, and quick retraction—optimizing cycle times without compromising accuracy. Traditional systems, limited by fixed pump speeds, cannot match this adaptability. Additionally, thermal stability plays a role; hybrids maintain oil temperatures below 50°C, preventing viscosity-induced errors that plague conventional machines during prolonged operation.

Case studies provide tangible evidence. A Midwest fabrication facility transitioning to a double-servo hybrid reported a 40% reduction in tolerance deviations on HVAC components, from ±0.7 degrees to ±0.3 degrees, boosting throughput by 28%. Similarly, in medical device manufacturing, where precision affects functionality, hybrids ensured compliance with FDA standards, avoiding costly recalls. These examples illustrate how precision enhancements not only elevate product quality but also contribute to operational resilience.

Energy Efficiency and Sustainability

Energy efficiency constitutes another core advantage of the electro-hydraulic servo CNC press brake, addressing the high consumption inherent in traditional hydraulic designs. Conventional systems maintain constant pump operation, resulting in idle energy draws of 50-70 kW and overall inefficiencies where up to 30% of power is lost to heat dissipation. This not only inflates operational costs but also exacerbates environmental footprints through increased carbon emissions.

Hybrid systems mitigate these issues by activating servo motors solely during bending cycles, achieving energy savings of 60-80%. Specific data from operational tests indicate that at 90% load over two hours, hybrids save 28-54% in energy while boosting efficiency by 30-50%. For a 100-ton machine, daily consumption drops from 60 kWh in hydraulics to 12 kWh, yielding annual savings of $5,000-8,000 at standard industrial rates.

From an engineering viewpoint, the servo pump configuration eliminates throttling losses associated with proportional valves in traditional setups, reducing hydraulic oil usage by 50-85%. This diminution in oil volume—often to one-third—lowers maintenance demands and minimizes leak risks, aligning with sustainability protocols like ISO 14001. Noise reduction is another benefit, with levels dropping 10-12 dB, enhancing workplace ergonomics.

Comparative statistics underscore these efficiencies. European manufacturing reports show hybrids cutting CO2 emissions by 40%, supporting green initiatives without performance trade-offs. In variable-load scenarios, the controllable servo action optimizes power delivery, achieving 75% reductions during standby. These attributes make hybrids ideal for energy-conscious sectors, where regulatory pressures demand lower consumption.

Structural Integrity and Reliability

The structural design of the electro-hydraulic servo CNC press brake enhances reliability, ensuring longevity in demanding environments. Traditional hydraulics, with their extensive piping and seals, are prone to failures, with mean time between failures (MTBF) around 7,500 hours due to leaks and contamination.

Hybrids employ finite element analysis (FEA) for key components like the frame and slider, limiting deflection to under 0.1 mm at maximum load. Unique welding techniques, such as mortise-and-tenon joints, distribute stress 25% more effectively than conventional welds, bolstering rigidity for high-intensity operations. Dual cylinders with mechanical synchronization ensure stable performance, while stainless steel oil tanks prevent pollution and simplify cleaning.

Reliability metrics show MTBF exceeding 15,000 hours, halving downtime compared to hydraulics. This durability stems from reduced fluid churn and fewer external pipelines, minimizing failure points. In rigorous testing, hybrids endured 10,000 cycles with no degradation in precision, underscoring their robustness for continuous production.

Advanced Controls and Automation Features

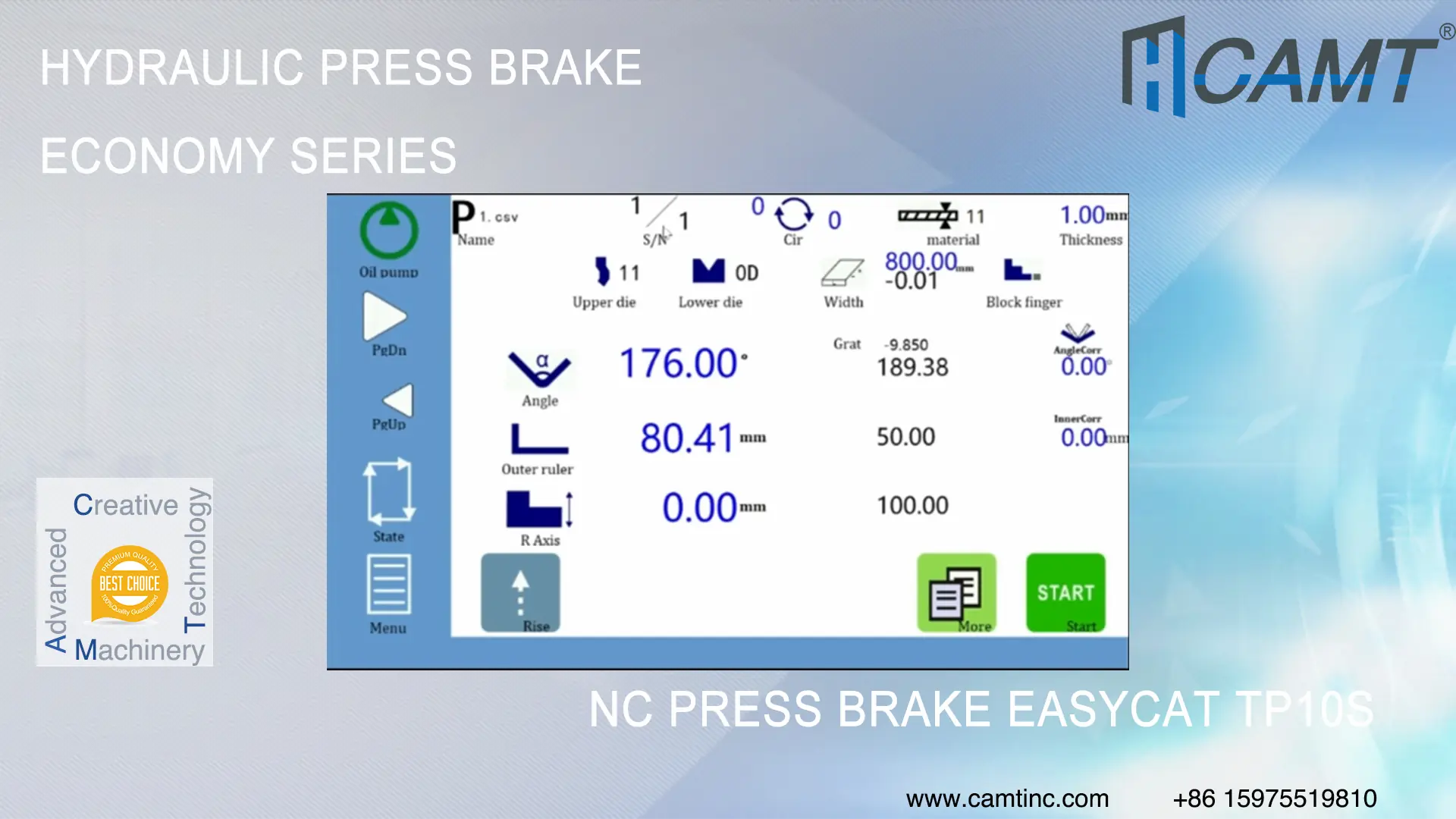

Advanced CNC systems in electro-hydraulic servo press brakes facilitate sophisticated automation, surpassing the basic PLCs of traditional models. Dedicated controllers enable multi-step programming, automatic sequencing, and real-time monitoring, with power-loss memory preserving positions and parameters.

Backgauges support configurations from 4+1 to 10+ axes, utilizing ball screws and linear guides for ±0.02 mm positioning accuracy. This scalability reduces setup times by 40% for complex geometries. Integration with AI-driven tool selection further streamlines operations, minimizing human intervention and errors.

Compared to hydraulics, these features enhance flexibility for high-mix production, with cycle speeds 20-35% faster. Industries like electronics benefit from this automation, achieving consistent outputs in variable runs.

Deflection Compensation Mechanisms

Deflection compensation is pivotal for maintaining bend straightness, and hybrids excel with mechanical crowning systems. These employ auto-adjusting wedges for multi-point pre-compensation, achieving ±0.1 mm parallelism on extended beds. Unlike reactive hydraulic compensation, mechanical approaches require no manual intervention, reducing scrap by 15-20%.

Technical superiority lies in system integration, where CNC algorithms predict and adjust for material deformation, ensuring quality across diverse workloads.

Real-World Applications and Case Studies

In practice, electro-hydraulic servo press brakes demonstrate versatility across sectors. In aerospace, a facility reported 25% reject reductions on brackets due to enhanced precision. Automotive suppliers noted 60% cycle time improvements on hems, with 80% noise cuts.

A comprehensive table illustrates comparisons:

Metric | Traditional Hydraulic | Electro-Hydraulic Servo | Improvement Percentage |

Energy Consumption (kWh/day) | 60 | 12 | 80% |

Bend Accuracy (degrees) | ±0.5 | ±0.2 | 60% |

Repeatability (mm) | ±0.1 | ±0.01 | 90% |

Cycle Time | Baseline | 20-35% faster | Up to 35% |

Oil Usage Reduction | N/A | 50-85% | N/A |

MTBF (hours) | 7,500 | 15,000 | 100% |

These data, aggregated from industry reports, affirm the hybrid’s edge.

In HVAC manufacturing, transitions yielded $12,000 annual savings and 28% output gains. Medical device producers achieved FDA compliance through micron-level accuracy, avoiding regulatory hurdles.

Cost-Benefit Analysis and ROI

Initial investment for hybrids is 20-30% higher—approximately $150,000 versus $110,000 for equivalents—but ROI materializes within 18-24 months. Factors include energy savings (50% of payback), reduced scrap (15-20%), and lower maintenance (40% cost reduction).

Long-term, adaptability to market demands enhances profitability, with hybrids supporting diverse materials without retooling.

Emerging Trends and Future Directions

Future developments may incorporate AI for predictive maintenance and IoT for remote monitoring, further elevating efficiency. Advances in materials science could reduce weights while maintaining rigidity, expanding applications.

Conclusion

The electro-hydraulic servo CNC press brake exemplifies technological synergy, offering unparalleled precision, efficiency, and reliability. Its advantages position it as a cornerstone for forward-thinking fabrication operations.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.