Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

Introduction: Why Press Brake Safety Precautions Matter

A press brake machine is a critical piece of equipment in sheet metal fabrication. Proper installation, correct operation, and regular maintenance are essential not only for product quality but also for operator safety and machine longevity.

Before installing, operating, or servicing any hydraulic or CNC press brake, operators must fully understand the safety precautions outlined in the operation manual. This guide expands on key press brake safety requirements to help users operate their machines safely and efficiently.

1. Read the Press Brake Operation Manual Before Installation and Use

Before any press brake installation, operation, or maintenance, carefully read the operation manual provided with the machine.

The manual serves as a permanent technical reference and includes:

• Installation instructions

• Operating procedures

• Safety warnings

• Maintenance guidelines

The manual must always be kept with the machine and handed over to the responsible operator or maintenance personnel. Following the manual based on real-world operating experience helps reduce downtime, prevent accidents, and extend the service life of the press brake.

If special operating conditions arise or additional technical support is required, users should contact the manufacturer’s after-sales service department, providing the machine model and serial number.

2. Main Applications of Hydraulic Press Brake Machines

2.1 What Is a Hydraulic Press Brake Used For?

A hydraulic press brake is designed to bend sheet metal into specific shapes by applying controlled pressure through a moving ram. In most cases, a single stroke produces a defined cross-sectional profile, while multiple strokes allow for more complex bending forms.

Hydraulic press brakes are widely used in:

• Electrical and mechanical manufacturing

• Light industry and agricultural machinery

• Shipbuilding and marine engineering

• Automotive and aerospace industries

Due to their versatility and precision, press brakes are considered ideal sheet metal bending machines.

3. Key Features of CNC Press Brake Machines

Modern CNC press brakes combine hydraulic power with advanced electrical and numerical control systems to achieve high accuracy and efficiency.

3.1 Advanced CNC Control System

• Upper dead point, lower dead point, and speed change points are controlled by the CNC system

• Fast and reliable parameter adjustment for different bending processes

• Improved repeatability and production efficiency

3.2 Pressure Return Function for Safer Bending

The press brake is equipped with a pressure return function, meaning once the preset bending pressure is reached, the CNC system automatically signals the ram to return. This feature improves safety, consistency, and tooling protection.

4. Press Brake Working Environment Requirements

To ensure stable performance and long-term reliability, the press brake working environment should meet the following conditions:

• Ambient temperature: 5°C – 40°C

• Relative humidity: 35% – 95% (no condensation or frost)

• Installation altitude: Below 1000 meters

• Lighting conditions: ≥ 500 LUX

• Installation environment:

• Free from toxic or corrosive gases

• No metal chips, excessive dust, or debris

A clean and well-controlled environment helps protect the CNC system and hydraulic components.

5. Press Brake Noise Levels and Operating Standards

The operating noise level of a hydraulic press brake depends on its nominal pressure. Standard noise limits are shown below:

Nominal Pressure | Noise Level |

|---|---|

P ≤ 630 kN | ≤ 82 dB(A) |

630 kN < P < 2500 kN | ≤ 85 dB(A) |

P ≥ 2500 kN | ≤ 88 dB(A) |

Regular maintenance of hydraulic components and proper machine leveling can help reduce noise during operation.

6. Essential Press Brake Usage Precautions

To prevent accidents and equipment damage, the following press brake safety precautions must always be observed:

1. Only trained and qualified operators are allowed to operate the press brake.

2. The press brake must be installed on a level foundation. Poor leveling may cause frame distortion and reduce bending accuracy.

3. During installation and maintenance, operators must wear Personal Protective Equipment (PPE) such as gloves and safety shoes.

4. Overloading and severe eccentric loading are strictly prohibited, as they may cause irreversible machine damage.

5. Materials processed on the press brake must be non-toxic and safe for operators.

6. Replacement parts must match the original specifications. If uncertain, contact the manufacturer’s after-sales service team.

7. Press Brake Safety Warnings and Risk Classification

Safety warnings in press brake manuals are divided into two levels:

• Danger:

Incorrect operation may lead to death or serious injury.

• Caution:

Incorrect operation may result in moderate injury, minor injury, or equipment damage.

Understanding and following these warnings is critical for safe press brake operation.

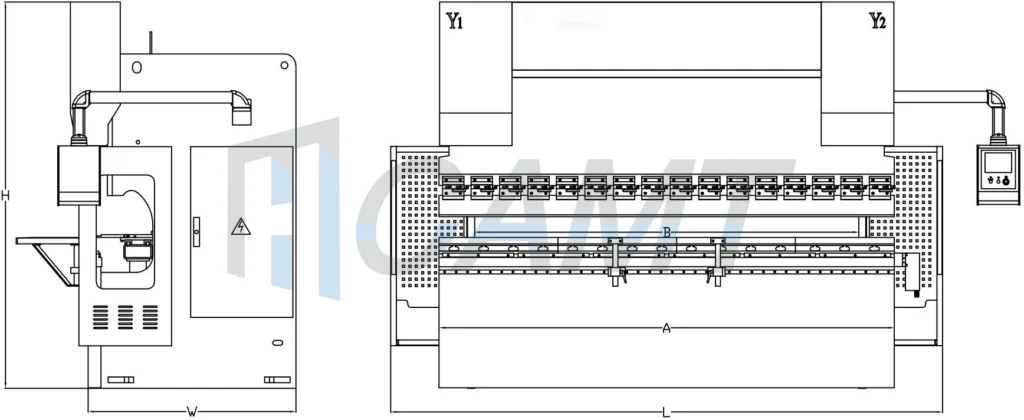

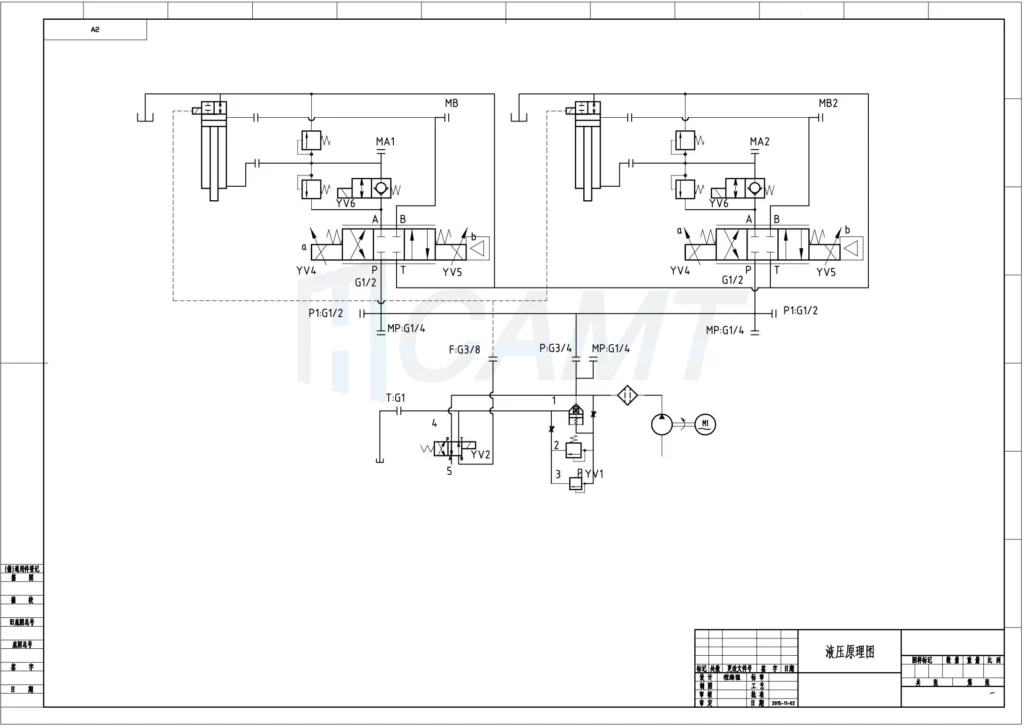

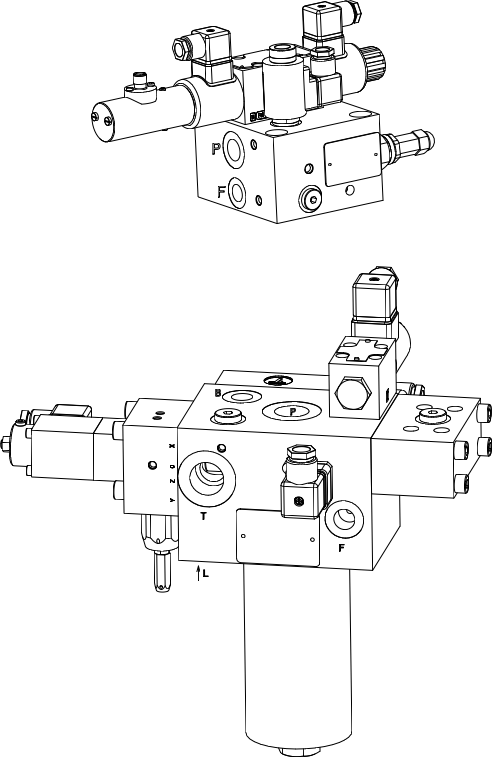

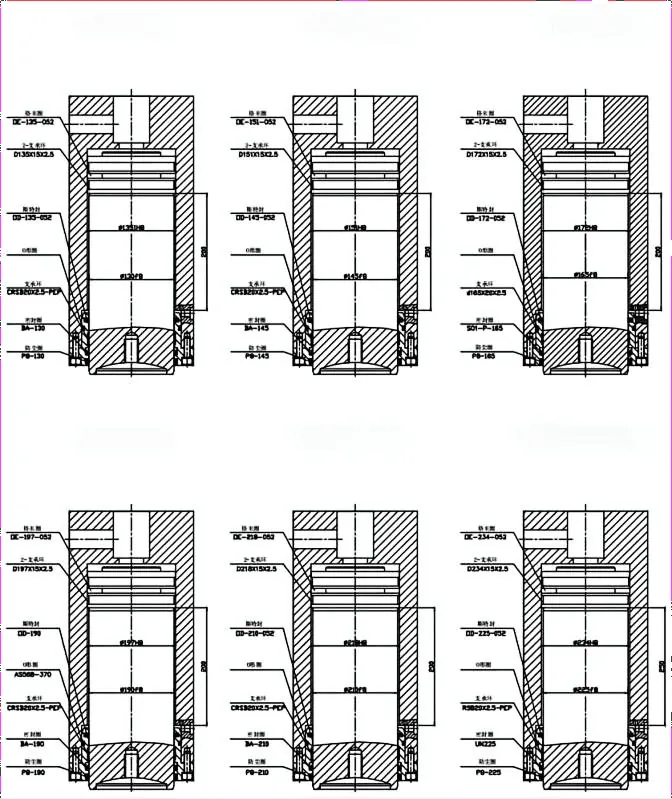

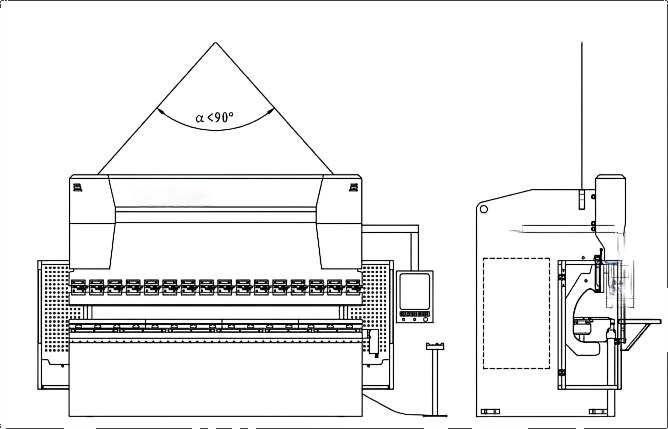

8. Press Brake Structure and Working Principle Overview

A typical CNC hydraulic press brake consists of:

• Machine frame

• Ram (slider)

• Hydraulic system

• CNC control system

• Back gauge system

• Upper and lower tooling

The hydraulic system includes synchronization valve blocks and pressure control valve groups to ensure smooth, synchronized ram movement.

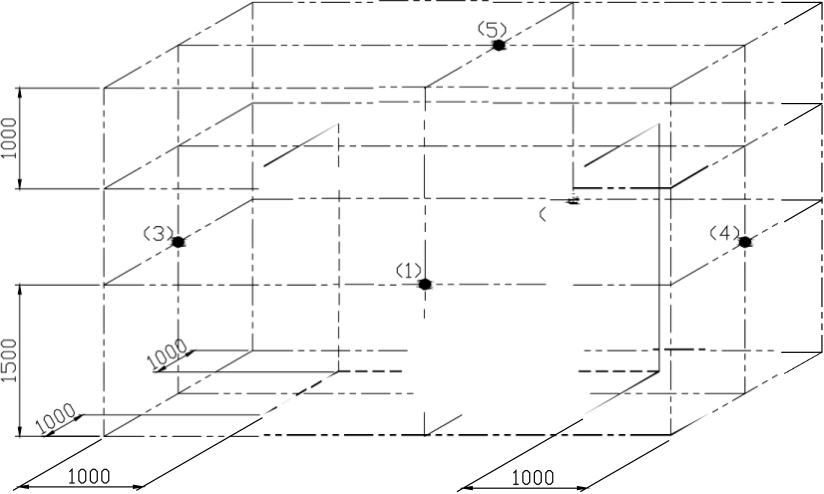

9. Press Brake Transportation and Storage Guidelines

9.1 Press Brake Lifting and Transportation Safety

• Lifting lugs are provided for safe hoisting

• Always select lifting equipment based on the actual machine weight

• Improper lifting may cause frame deformation or permanent damage

During transportation:

• Secure the machine firmly

• Protect it from rain and moisture

• Drive slowly on uneven roads to avoid vibration and impact

9.2 Press Brake Storage Conditions

• Storage temperature: -25°C to 55°C

• Short-term storage (less than 24 hours): up to 70°C

• Apply effective moisture-proof, vibration-proof, and shock-resistant measures

Proper storage helps prevent corrosion and component damage.

Conclusion: Safe Press Brake Operation Improves Efficiency and Service Life

Following these press brake safety precautions ensures safer operation, higher bending accuracy, and longer machine lifespan. Proper installation, professional operation, and regular maintenance are the foundation of reliable sheet metal bending.

If you require technical support or are looking for a reliable CNC press brake manufacturer, feel free to contact our experienced service team for professional assistance.

Press Brake Safety FAQs

Why are press brake safety precautions important?

Press brake safety precautions are essential to protect operators from injury, prevent equipment damage, and ensure consistent bending accuracy. Proper safety practices also help extend the service life of the press brake machine.

Who is allowed to operate a CNC press brake?

Only trained and qualified personnel are allowed to operate a CNC press brake. Operators must understand the machine structure, control system, and safety instructions before using the bending machine.

What should be checked before installing a press brake machine?

Before installing a press brake machine, ensure the foundation is level, the working environment meets temperature and humidity requirements, and all safety instructions in the operation manual are fully understood.

What is the recommended working environment for a hydraulic press brake?

The recommended working environment for a hydraulic press brake includes a temperature range of 5°C to 40°C, humidity between 35% and 95% without condensation, sufficient lighting, and an area free from toxic gases and metal debris.

Can a press brake be operated under overload conditions?

No, operating a press brake under overload or severe eccentric load conditions is strictly prohibited. Overloading may cause serious damage to the machine frame, hydraulic system, and tooling.

What is the pressure return function on a CNC press brake?

The pressure return function allows the press brake ram to automatically return once the preset bending pressure is reached. This feature improves operational safety, bending consistency, and tool protection.

What personal protective equipment is required when operating a press brake?

Operators should wear appropriate personal protective equipment such as safety gloves, safety shoes, and protective clothing when installing, operating, or maintaining a press brake machine.

How can proper maintenance improve press brake service life?

Proper maintenance, including regular inspection, correct lubrication, use of original spare parts, and operation according to the manual, can significantly extend the service life and performance stability of a press brake.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.