Practical Methods for Press Brake Accuracy with Long Term Precision

Introduction about press brake accuracy

Press brake accuracy is a key factor in sheet metal bending quality. In actual production, accuracy problems usually appear gradually, not suddenly. Most machines that are installed correctly and operated within their design limits do not require frequent mechanical adjustment. In daily use, bending deviations are more often related to material variation, tooling condition, or parameter settings rather than machine structure.

Mechanical accuracy adjustment should only be considered during major machine overhauls, long-term heavy use, or after relocation. These adjustments require experience and proper measuring methods. For this reason, end users are not advised to perform them independently and should contact the machine manufacturer or qualified service personnel.

General Understanding of Press Brake Accuracy

Press brake accuracy is not defined by a single value. It is the combined result of frame rigidity, guideway condition, ram motion, backgauge positioning, and tooling setup. If any of these elements are out of alignment, bending consistency will be affected.

Before adjusting the machine itself, it is important to confirm that tooling is correctly installed, material thickness is consistent, and CNC parameters are properly set. Mechanical adjustment should always be the last step, not the first reaction.

General Understanding of Press Brake Accuracy

Purpose of Guideway Adjustment

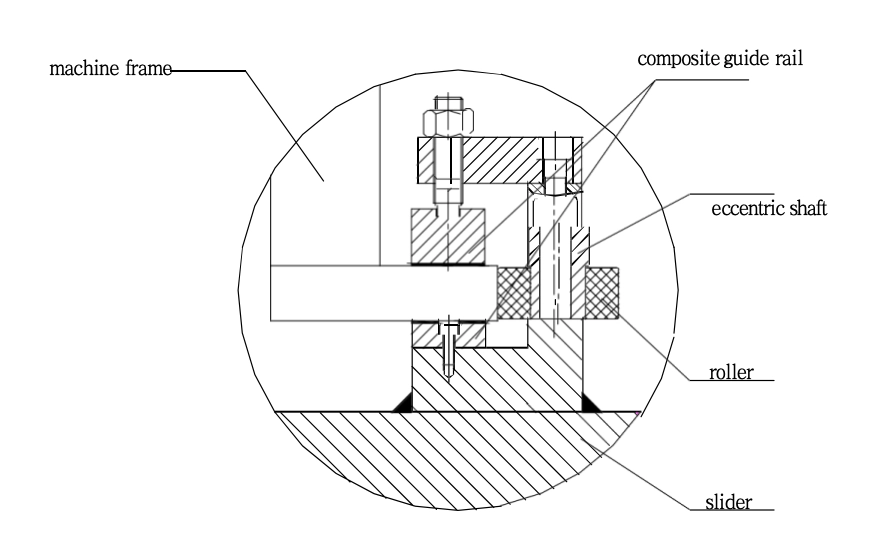

The guideway controls the vertical movement of the ram. If the ram is not perpendicular to the worktable, bending angles will vary along the length of the part. This problem becomes more noticeable when bending long workpieces or using full-length tooling.

Adjustment Method

Guideway adjustment is usually carried out by adjusting the set screws located on the rear side of the guide rails. These screws change the position of the sliding block and correct the vertical deviation of the ram stroke.

After adjustment, the clearance between guideway surfaces should be no more than 0.05 mm. At the same time, the guideways must not be adjusted too tightly. Excessive preload will increase friction and may reduce fast approach speed or cause unstable movement.

Practical Notes

Measurements should be taken at several positions along the ram stroke using suitable measuring tools. Adjustment should be gradual, with small corrections made each time. After mechanical alignment, test bending should be carried out to confirm results under actual load conditions.

Backgauge Accuracy and Parallelism

Function of the Backgauge

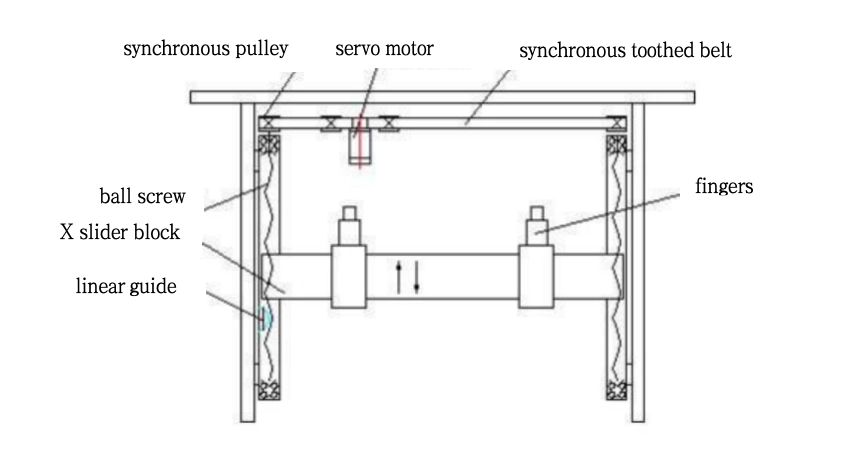

The backgauge determines flange length. If the backgauge beam is not parallel to the tooling centerline, the flange length will differ between the left and right sides of the part. This type of error is usually repeatable and cannot be corrected by CNC settings alone.

Identifying Backgauge Misalignment

Typical signs include consistent flange length deviation across the machine width or visual misalignment between the backgauge beam and the die center. In such cases, mechanical synchronization should be checked.

Relationship Between Mechanical Accuracy and CNC Compensation

CNC compensation functions are designed to fine-tune bending results, not to correct mechanical errors. If mechanical alignment is poor, compensation values will increase and system stability will decrease. For reliable long-term accuracy, mechanical alignment must be correct before CNC calibration is applied.

Maintenance and Accuracy Stability

Maintaining press brake accuracy depends largely on regular inspection and proper maintenance. Guideways and ball screws should be lubricated according to manufacturer recommendations. Backgauge components should be checked for wear and synchronization. Recording bending results over time helps identify gradual changes before they become serious problems.

Recommendation on Accuracy Adjustment

Press brake accuracy adjustment involves structural understanding and practical experience. Incorrect adjustment can reduce machine life or create new problems. For this reason, users are strongly advised to contact the manufacturer or authorized service technicians when mechanical accuracy adjustment is required.

Additional Factors Affecting Press Brake Accuracy

Machine Frame and Structural Stability

The machine frame is the base of all bending accuracy. Even with correct guideway and backgauge alignment, a press brake with insufficient rigidity will show accuracy variation under load. This is more common on long machines or when bending high-strength materials. Frame deformation usually appears as angle deviation in the middle or ends of the workpiece. In such cases, mechanical adjustment alone will not fully solve the problem, and crowning or process optimization must be considered.

Tooling Condition and Installation

Tooling accuracy is often overlooked during troubleshooting. Worn punches or dies, uneven seating surfaces, or incorrect clamping can all introduce bending errors. Before judging machine accuracy, tooling should be inspected for wear and installed evenly along the full length. Even small height differences between tool segments can affect bending results, especially on precision parts.

Material Influence on Bending Accuracy

Material thickness tolerance, tensile strength variation, and surface condition all influence bending results. In batch production, differences between material lots may be mistaken for machine accuracy problems. Experienced operators usually verify material consistency before requesting mechanical adjustment. This step can prevent unnecessary service work.

Accuracy Verification After Adjustment

After any mechanical adjustment, accuracy verification should be carried out under real working conditions. This includes test bends at different positions along the machine length and repeated cycles to check consistency. Measurements should focus on angle repeatability and flange length stability rather than single test results.

It is also recommended to record these measurements as a reference for future maintenance. Trend data helps identify gradual changes and supports preventive service planning.

Common Misunderstandings About Press Brake Accuracy

One common misunderstanding is assuming that CNC display values always represent actual bending results. In reality, CNC values reflect target positions, not mechanical condition. Another misconception is that frequent adjustment improves accuracy. Excessive adjustment often leads to faster wear and unstable performance.

Accurate machines are usually those that are adjusted correctly once and then maintained properly, rather than adjusted repeatedly.

Role of Professional Service Support

Professional service engineers do more than follow adjustment procedures. They evaluate overall machine condition, identify root causes, and balance mechanical settings with long-term reliability. This experience cannot be replaced by written instructions alone.

For users operating high-precision or high-value production lines, professional service support is an important part of maintaining press brake accuracy over time.

Conclusion

Press brake accuracy depends on multiple mechanical and process-related factors. Guideway alignment and backgauge parallelism form the foundation, but frame rigidity, tooling condition, and material consistency also play important roles. Under normal operation, mechanical adjustment is not required. During major overhaul or long-term use, professional adjustment ensures stable and repeatable bending results.

A systematic approach to accuracy, combined with proper maintenance and service support, is the most reliable way to achieve long-term press brake precision.

FAQ

What is press brake accuracy?

Press brake accuracy refers to the machine’s ability to produce consistent bending angles and flange lengths within defined tolerances.

Why does accuracy change over time?

Wear of guideways, ball screws, tooling, and structural stress accumulation can gradually affect accuracy.

Is backgauge accuracy more important than angle accuracy?

Both are important. Backgauge accuracy affects part dimensions, while angle accuracy affects assembly and fit.

Can frequent adjustment improve accuracy?

No. Unnecessary adjustment often causes instability and increased wear.

Who should perform accuracy adjustment?

Accuracy adjustment should be performed by experienced service engineers or the machine manufacturer.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.