Press Brake Maintenance and Repair

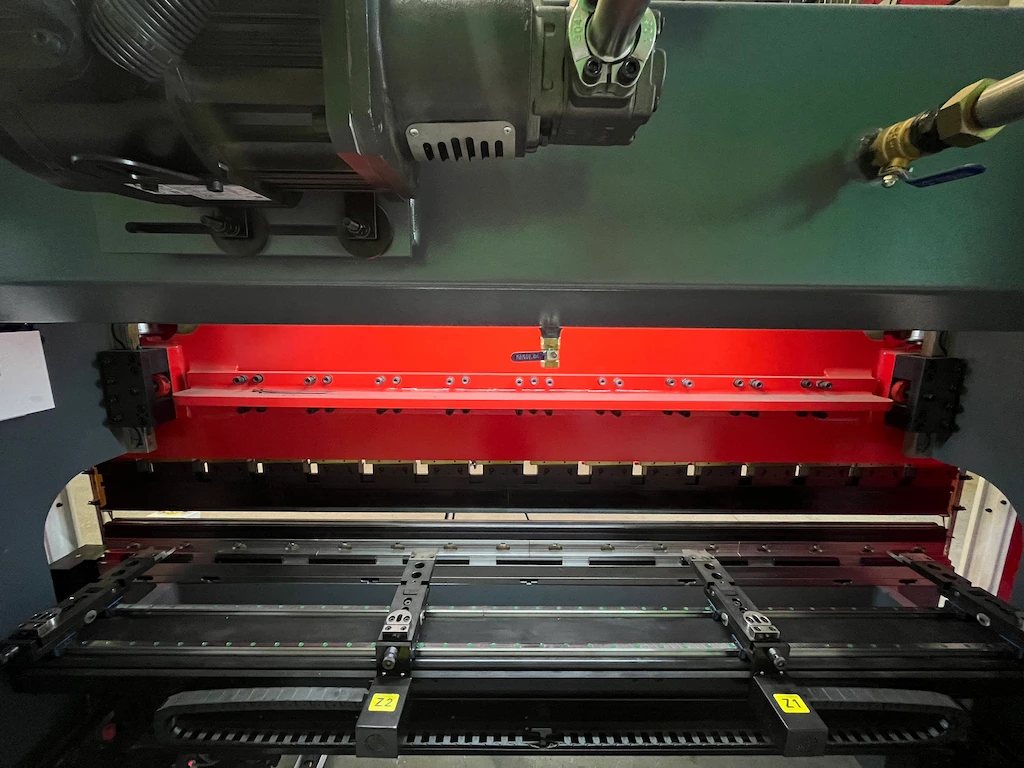

Press brake maintenance and repair play a decisive role in the long-term performance of a bending machine. In actual factory conditions, many problems that appear to be sudden failures are in fact the result of accumulated wear, insufficient lubrication, or delayed inspection. A press brake is a high-load, high-precision machine, and its condition directly affects bending accuracy, production efficiency, and overall operating cost.

From an engineering perspective, maintenance is not only about preventing breakdowns. It is also about maintaining stable accuracy over time. Machines that are cleaned, lubricated, and inspected regularly tend to show predictable behavior, making process control much easier. In contrast, machines that receive attention only after problems appear often develop multiple hidden issues at the same time. This article explains press brake maintenance and repair based on common technical documentation and long-term field experience, focusing on practical solutions rather than theoretical descriptions.

Primary keyword: press brake maintenance Secondary keywords: press brake repair, hydraulic system maintenance, press brake lubrication, CNC press brake service, press brake accuracy stability

Lubrication as the Foundation of Press Brake Maintenance

Lubrication is one of the most fundamental maintenance tasks, yet it is often underestimated. During normal operation, the ram guideways, linear motion systems, and rotating components are constantly subjected to friction and load. Without sufficient lubrication, metal-to-metal contact increases rapidly, leading to accelerated wear, rising clearances, and gradual loss of accuracy. Once wear reaches a certain level, adjustment alone can no longer restore original performance.

Operators should be familiar with all lubrication points on the machine and understand their function. Lubrication should be treated as a routine production task rather than a special maintenance activity. In many cases, machines that show unstable motion or noise problems can be significantly improved simply by restoring proper lubrication practices.

Main Lubrication Points and Frequency

The main lubrication points on a press brake typically include the ram guideways, X-axis and R-axis drive mechanisms, backgauge linear guide rails, ball screws, and exposed wear-prone components that do not have dedicated lubrication points. Examples include certain cylinder connection areas and linkage joints. These parts are often overlooked because they are not connected to centralized lubrication systems.

Under standard operating conditions, lubrication should be carried out twice per week. In high-duty cycles or dusty environments, more frequent lubrication may be required. It is important to use lubricants recommended by the manufacturer, as incorrect viscosity or additives can reduce effectiveness or even cause damage.

Lubrication Quality and Common Mistakes

Applying lubricant is not only about quantity. Over-lubrication can attract dust and metal particles, forming abrasive paste that accelerates wear. Before applying new lubricant, old grease and contamination should be removed where possible. Consistent lubrication quality helps maintain smooth motion and reduces long-term maintenance costs.

Hydraulic System Maintenance and Reliability

The hydraulic system is the power source of the press brake and has a direct influence on bending force stability and motion control. Even minor hydraulic issues can lead to unstable ram movement, inconsistent bending angles, or reduced productivity. Many press brake service calls are related to hydraulic problems that could have been avoided through proper maintenance.

Hydraulic Oil Management

Hydraulic oil performs several critical functions, including power transmission, internal lubrication, heat dissipation, and contaminant transport. Regular inspection of the oil level in the tank is essential. If the oil level is too low, air may enter the system, causing noise, vibration, and pressure instability.

The first hydraulic oil change should be performed after approximately 500 working hours. This initial oil change removes manufacturing residues, assembly contaminants, and early wear particles. After this first replacement, hydraulic oil should be changed every 2000 working hours. In high-temperature environments or heavy-duty applications, shorter intervals may be necessary to maintain oil quality.

Oil Cleanliness and System Protection

Oil cleanliness has a direct impact on the service life of hydraulic components. Contaminated oil can cause valve sticking, internal leakage, and accelerated wear of pumps and cylinders. Maintaining clean oil reduces the risk of unexpected failure and improves overall system response. Regular oil analysis, where available, can provide early warning of contamination or degradation.

Hydraulic Filter Replacement

Hydraulic filters protect sensitive components by capturing solid particles and contaminants. Filter elements should be replaced regularly, typically at the same time as hydraulic oil replacement. Delaying filter replacement reduces filtration efficiency and allows contaminants to circulate within the system.

A clogged filter can restrict oil flow, leading to insufficient suction and abnormal pump noise. If the machine is equipped with filter clogging indicators, these should be monitored closely. Replacing filters on schedule is a low-cost measure that prevents expensive component damage.

Air Breather Filter Maintenance

The air breather filter is installed on the hydraulic oil tank and allows air exchange while preventing dust and moisture from entering the system. After initial machine commissioning, the first cleaning should be carried out approximately two months later. The filter element should be cleaned using suitable solvents such as gasoline or trichloroethylene.

After the initial cleaning, the air breather should be cleaned every four months. In dusty or humid environments, more frequent cleaning may be required. A blocked air breather can create negative pressure inside the oil tank, affecting oil flow and causing unstable system behavior.

Hydraulic Connections and Sealing

Hydraulic leaks should never be ignored, even if they appear minor. Leakage at pipe connections often indicates loose fittings or damaged sealing surfaces. Tightening the fitting may solve the problem temporarily, but if leakage continues, the fitting should be replaced. In some cases, high-pressure hoses in the hydraulic circuit also require replacement due to aging or fatigue.

If leakage occurs at valve blocks, O-rings or combined seals should be replaced promptly. Delayed action can lead to contamination, pressure loss, and safety hazards. Addressing leaks early helps maintain system cleanliness and operating stability.

Mechanical Component Inspection and Preventive Maintenance

Mechanical components provide the structural integrity of the press brake. Wear or misalignment in these parts usually develops gradually and may not be immediately visible. Regular inspection helps identify early signs of wear before they affect accuracy or cause failure.

Inspection of Mechanical Parts

All mechanical parts should be checked periodically, including bearings, fasteners, support brackets, and structural connections. Loose bolts or worn components can introduce vibration and reduce positioning accuracy. During inspection, attention should be paid to abnormal noise, uneven movement, or visible wear marks.

Synchronization and Transmission Systems

Synchronization systems, such as synchronous belts and related transmission mechanisms, are critical for maintaining left-right consistency. This is especially important for backgauge systems and long machines. Belt wear, incorrect tension, or pulley misalignment can cause positioning deviation and repeatability problems. Regular inspection and timely replacement prevent gradual accuracy loss.

Guideways and Linear Motion Systems

Guideways and linear rails should be kept clean and properly lubricated. Chips, dust, or hardened grease can damage rolling elements and increase friction. Smoothness checks during manual or slow-speed movement can help identify early-stage wear. Proper maintenance of guideways supports stable ram motion and consistent bending results.

Maintenance, Repair, and Press Brake Accuracy

There is a strong relationship between maintenance quality and press brake accuracy. Lubrication affects guideway clearance, hydraulic oil condition influences pressure stability, and mechanical wear changes motion repeatability. Many accuracy issues can be traced back to maintenance-related causes rather than design or control problems.

A preventive maintenance approach reduces the need for corrective repair and minimizes production interruption. Machines that are maintained systematically tend to require fewer major repairs and retain stable accuracy for longer periods.

When Repair Becomes Necessary

Despite proper maintenance, wear is inevitable over long-term operation. Repair becomes necessary when components reach their service limits or when abnormal conditions persist despite routine maintenance. Typical signs include recurring hydraulic leaks, abnormal noise, unstable ram movement, and inconsistent bending results.

At this stage, professional diagnosis is essential. Replacing parts without identifying the root cause often leads to repeated failure. Experienced service personnel can evaluate overall machine condition and recommend appropriate repair actions.

Conclusion

Press brake maintenance and repair should be viewed as an ongoing process rather than a reaction to failure. Proper lubrication, careful hydraulic system management, and regular mechanical inspection form the foundation of reliable machine operation. These practices not only reduce downtime but also help maintain consistent bending accuracy over the machine’s service life.

For complex repairs or accuracy-related problems, cooperation with the machine manufacturer or authorized service providers remains the most effective approach.

FAQ: Press Brake Maintenance and Repair

How often should a press brake be lubricated?

Most lubrication points should be serviced twice per week, depending on usage and environment.

When should hydraulic oil be replaced?

The first oil change is recommended after 500 working hours, followed by replacement every 2000 working hours.

What causes most hydraulic system failures?

Oil contamination, clogged filters, and delayed maintenance are common causes

Can regular maintenance improve bending accuracy?

Yes. Proper maintenance stabilizes mechanical and hydraulic conditions, which directly supports accuracy.

When should professional repair service be contacted?

When persistent issues such as leaks, abnormal noise, or unstable motion occur despite routine maintenance.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.