How to Choose the Right Press Brake System

$20,000–$35,000 Aerospace, automotive high-precision ESA (S.A.N.C.).

Hybrid/electric optimization, advanced servo integration.

$18,000–$30,000

Electric press upgrades.

Mid-Range

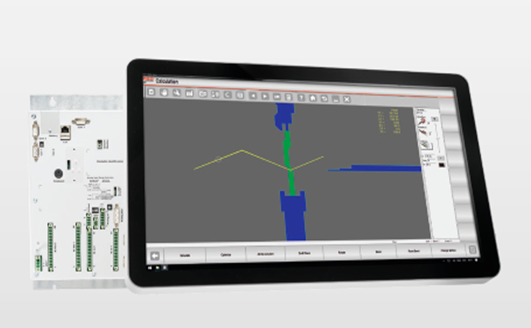

Beckhoff (TwinCAT), Bosch Rexroth (Cytronic)

- Open architecture, customizable PLCs, strong networking $10,000–$20,000.

- Custom automation, mid-volume WILA (Smart Tooling integration).

- Tooling-focused, user-friendly for mixed batches $8,000–$15,000.

- General fabrication Entry-Level.

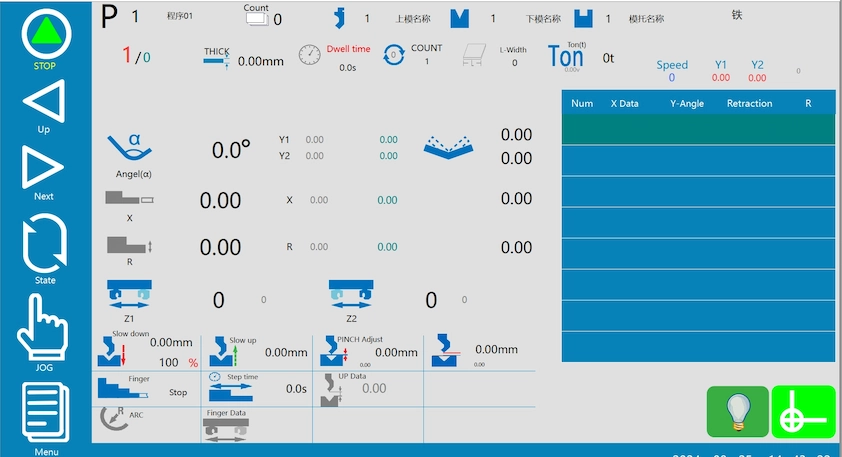

Generic OEM (e.g., Chinese/ Taiwanese like CypCut), Basic Hydrapower.

Simple CNC, manual overrides, cost-effective basics

$3,000–$8,000.

- Low-volume, starter shops Premium Brands:.

- Cybelec’s stability shines in 24/7 ops; Delem’s DA series dominates with 50% market share (per 2024 SEMI reports) for its bend simulation wizardry. Mid-Range:.

- Beckhoff’s PC-based openness lets coders tweak for IoT. Rexroth excels in rugged environments. Entry-Level:.

Solid for startups, but upgrade paths are limited. Domestic brands like those from Accurl offer value with growing software support.

Match to your scale: Premium for ROI in precision; entry for bootstraps.

Step-by-Step Guide to Selecting Your Press Brake Control System.

Don’t wing it—follow this roadmap for a regret-free buy.

1.Define Your Requirements List:

Jot down specs: Tolerances (±0.2° angles?), materials (mild steel up to 12mm?), volume (500 pcs/week?), budget ($15K max). List must-haves like 3D sim or robot I/O.

2.Research Models:

Use tools like Ahrefs or Google for reviews. Shortlist 3–5: E.g., Delem for versatility, CypCut for budget. Download datasheets—cross-check axis specs.

- 3.Request Quotes and Proposals: Hit up distributors for tailored bids. Ask for ROI calcs (e.g., payback in 18 months via efficiency).

- 4.Review Demos and Videos: YouTube or supplier portals show real workflows. Watch for lag in touch response or sim accuracy.

- 5.Hands-On Testing (Essential): Visit trade shows like FABTECH or factories. Bring sample drawings—test a bend sequence. Measure outputs with calipers for true precision.

6.Vet Support and Service:.

Query response times (under 24hrs?), local techs, and update policies. Check forums like Practical Machinist for user gripes.

7.Weigh and Decide:.

- Score options on a matrix: 40% performance, 20% ease, 20% cost, 10% support, 10% scalability. Pull the trigger on the balanced winner.This process, honed from years advising shops, typically saves 15–20% on mismatched buys.

- Key Considerations and Common Pitfalls Even pros trip up—here’s how to sidestep.

- Beyond Price: A $4K system might nickel-and-dime you with $10K annual downtime. Calculate TCO: Initial + maintenance + training.

Scalability:.

Will it handle tomorrow’s robot arm? Modular systems future-proof.

Training Investment:.

- Allocate 8–16 hours per operator. Intuitive UIs cut this, but budget $500–$1,000 for certs. Machine Matching:.

- Stick to OEM-recommended pairings. Aftermarket? Test compatibility rigorously. True Metrics:.

- Accuracy and Efficiency: Judge by output—consistent bends at speed—not specs. Aim for <5% variance in angle runs. In essence, the best press brake system harmonizes your now with your next. High-precision demands scream for elites like Delem; everyday wins go to value mids like Beckhoff.

- Empower Your Bends with the Right Choice Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow.

Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow.

Jane Smith

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.

- All Products V-Grooving Machine.

- Punchine Machine Related News.

- How to Properly Install a Press Brake Machine Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance.

blog.

cnc control system

press brake machine.

- press brake safety Empower Your Bends with the Right Choice.

- Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow. Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow.

- Read more about Principle and Function of Press Brake Safety Protection System Read more about Press Brake Maintenance and Repair.

Read more about Practical Methods for Press Brake Accuracy with Long Term Precision.

Read more about Practical Guidance For Press Brake Operation

Read more about How to Properly Install a Press Brake Machine.

Nivel | Ejemplos de Marca | Puntos Fuertes Clave | Rango de Precios (USD) | Ideal Para |

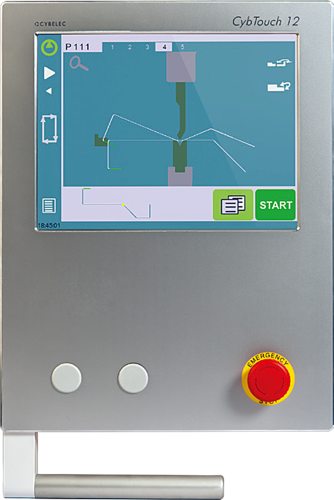

Premium | Cybelec (Cybelec CybTouch), Delem (DA-66T/69T) | Control de ángulo ultrapreciso, simulación 3D, multieje sin interrupciones | $20,000–$35,000 | Aeroespacial, automotriz de alta precisión |

Premium | ESA (S.A.N.C.) | Optimización híbrida/eléctrica, integración avanzada de servomotores | $18,000–$30,000 | Actualizaciones de prensas eléctricas |

Gama Media | Beckhoff (TwinCAT), Bosch Rexroth (Cytronic) | Open architecture, customizable PLCs, strong networking | $10,000–$20,000 | Custom automation, mid-volume |

Gama Media | WILA (Smart Tooling integration) | Tooling-focused, user-friendly for mixed batches | $8,000–$15,000 | General fabrication |

Entry-Level | Generic OEM (e.g., Chinese/ Taiwanese like CypCut), Basic Hydrapower | Simple CNC, manual overrides, cost-effective basics | $3,000–$8,000 | Low-volume, starter shops |

- Premium Brands: Cybelec’s stability shines in 24/7 ops; Delem’s DA series dominates with 50% market share (per 2024 SEMI reports) for its bend simulation wizardry.

- Mid-Range: Beckhoff’s PC-based openness lets coders tweak for IoT. Rexroth excels in rugged environments.

- Entry-Level: Solid for startups, but upgrade paths are limited. Domestic brands like those from Accurl offer value with growing software support.

Match to your scale: Premium for ROI in precision; entry for bootstraps.

Step-by-Step Guide to Selecting Your Press Brake Control System

Don’t wing it—follow this roadmap for a regret-free buy.

1.Define Your Requirements List: Jot down specs: Tolerances (±0.2° angles?), materials (mild steel up to 12mm?), volume (500 pcs/week?), budget ($15K max). List must-haves like 3D sim or robot I/O.

2.Research Models: Use tools like Ahrefs or Google for reviews. Shortlist 3–5: E.g., Delem for versatility, CypCut for budget. Download datasheets—cross-check axis specs.

3.Request Quotes and Proposals: Hit up distributors for tailored bids. Ask for ROI calcs (e.g., payback in 18 months via efficiency).

4.Review Demos and Videos: YouTube or supplier portals show real workflows. Watch for lag in touch response or sim accuracy.

5.Hands-On Testing (Essential): Visit trade shows like FABTECH or factories. Bring sample drawings—test a bend sequence. Measure outputs with calipers for true precision.

6.Vet Support and Service: Query response times (under 24hrs?), local techs, and update policies. Check forums like Practical Machinist for user gripes.

7.Weigh and Decide: Score options on a matrix: 40% performance, 20% ease, 20% cost, 10% support, 10% scalability.

Pull the trigger on the balanced winner.This process, honed from years advising shops, typically saves 15–20% on mismatched buys.

Key Considerations and Common Pitfalls

Even pros trip up—here’s how to sidestep.

- Beyond Price: A $4K system might nickel-and-dime you with $10K annual downtime. Calculate TCO: Initial + maintenance + training.

- Scalability: Will it handle tomorrow’s robot arm? Modular systems future-proof.

- Training Investment: Allocate 8–16 hours per operator. Intuitive UIs cut this, but budget $500–$1,000 for certs.

- Machine Matching: Stick to OEM-recommended pairings. Aftermarket? Test compatibility rigorously.

- True Metrics: Accuracy and Efficiency: Judge by output—consistent bends at speed—not specs. Aim for <5% variance in angle runs.

In essence, the best press brake system harmonizes your now with your next. High-precision demands scream for elites like Delem; everyday wins go to value mids like Beckhoff.

Empower Your Bends with the Right Choice

Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow.

Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow.

All Products.

V-Grooving Machine

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

- Hydraulic Press Machine

- Read more about Practical Methods for Press Brake Accuracy with Long Term Precision

- Rolling Machine

- Ironworker

- Press Brake Tooling

- Machinery Accessories