How to Choose the Right Press Brake System

In the world of metal fabrication, selecting the perfect press brake system can make or break your shop’s efficiency and output quality. Whether you’re running a high-volume production line or tackling custom prototypes, the control system is the brain behind every precise bend. It’s not just about bending metal—it’s about minimizing waste, reducing setup times, and ensuring your team can hit those tight tolerances without breaking a sweat.

This comprehensive guide dives deep into everything you need to know about choosing a press brake system. We’ll break down key factors, essential features, top brands, and a step-by-step selection process. By the end, you’ll have the tools to balance your processing needs with your budget, ensuring you invest in a system that boosts productivity without unnecessary frills. Let’s get started.

Core Factors to Consider When Selecting a Press Brake System

Choosing the right press brake system starts with aligning your machine’s capabilities to your real-world demands. Overlooking this can lead to costly mismatches—like a high-end system gathering dust on a basic setup or a budget controller failing under complex jobs. Here’s what to evaluate first.

1. Your Processing Needs and Precision Requirements

Every shop has unique workflows, and your press brake system must match them. Start by auditing your typical jobs: What kind of parts are you producing? Simple brackets or intricate aerospace components?

- Workpiece Complexity: If you’re dealing with frequent angle changes or multi-step sequences (like hems, offsets, or compound bends), you’ll need a robust press brake controller. Basic systems handle straightforward bends, but complex ones demand intuitive programming to avoid errors. For instance, in automotive stamping, where sequences can involve 20+ steps, a system with automated sequencing saves hours.

- Precision Demands: Tolerance is king in precision work. Aim for angle accuracy of ±0.1° for high-end jobs (think medical devices or electronics enclosures) versus ±0.5° for general fabrication. Backgauge positioning should hit ±0.05mm for tight fits. According to industry benchmarks from the Fabricators & Manufacturers Association (FMA), shops achieving sub-0.1° consistency report up to 30% less scrap.

- Material Types and Thickness: High-strength steels, aluminum alloys, or thick plates (over 10mm) require advanced deflection compensation. A good press brake system adjusts for material springback dynamically, preventing cracks or distortions. For stainless steel runs, look for systems that factor in yield strength variations.

- Production Volume: High-volume runs thrive on automation features like batch programming and tool libraries. Low-volume or prototyping? Prioritize quick-setup modes that let operators tweak on the fly without deep coding knowledge.

By mapping these, you avoid overbuying. A mid-tier system might suffice for 80% of shops, but if you’re in aerospace, skimping on precision could cost thousands in rework.

2. The Press Brake Machine Itself

Your press brake system doesn’t operate in a vacuum—it must sync with the machine’s hardware. Mismatches here lead to sluggish performance or outright failures.

- Machine Type and Tonnage: Small hydraulic presses (under 100 tons) pair well with entry-level controllers. Larger electro-hydraulic or fully electric models (200+ tons) need high-response systems to handle servo valves or direct-drive motors. Electric presses, gaining popularity for energy efficiency (up to 50% savings per the European Association of Machine Tool Industries), often come with integrated CNC press brake controls.

- Axis Configuration: A single Y-axis setup controls the ram uniformly, fine for basic bends. Dual Y-axes (independent cylinders) enable crowning for parallelism, demanding a controller that supports real-time synchronization. Add Z (backgauge height), R (rotation), and X (position) axes for versatility—essential for 3D bending. Systems like those from Delem excel here, offering multi-axis interpolation for seamless multi-tool ops.

- Drive System Compatibility: Hydraulic systems need controllers with pressure feedback loops. Servo-electric ones prioritize speed and accuracy, often bundling proprietary software. Hybrid drives? Ensure the press brake control system handles both for optimal torque distribution.

Pro tip: Consult your machine’s OEM specs early. Retrofitting a mismatched controller can void warranties and add $5,000–$15,000 in costs.

3. Budget Constraints and Long-Term Value

Press brake systems range from $5,000 for basics to $30,000+ for premium setups. But cheap isn’t always smart—factor in total ownership costs like training, downtime, and upgrades.

Set a realistic range: Allocate 10–20% of your machine’s total cost to the controller. Mid-range options often deliver 80% of top-tier performance at half the price. Remember, a reliable system cuts labor by 20–40% over time, per studies from the International Sheet Metal Working Association.

Evaluating Key Features of a Press Brake Control System

Once you’ve nailed the basics, zoom in on features. A great press brake system isn’t just hardware—it’s software that anticipates your needs.

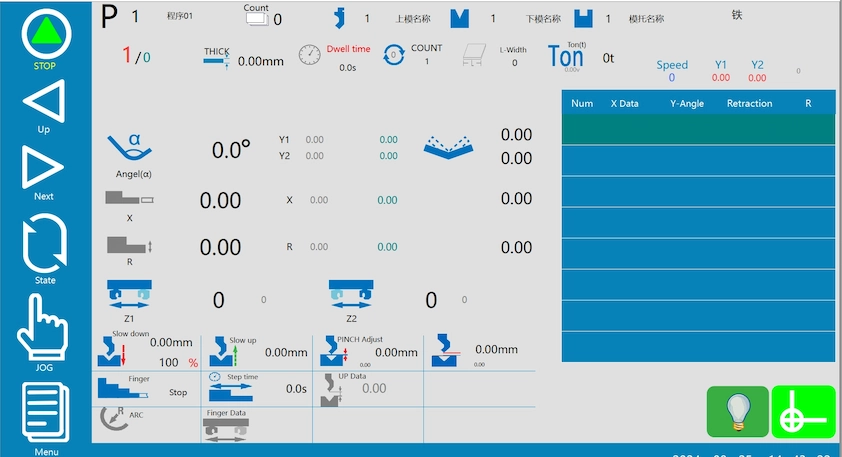

1. User Interface and Human-Machine Interaction

The interface is your daily touchpoint. A clunky one frustrates operators; a slick one boosts throughput.

- Display Quality: Opt for 15–21-inch touchscreens with 1080p+ resolution, IP65-rated for shop grime. Anti-glare coatings prevent eye strain during long shifts.

- Software Usability: Look for intuitive OS like Windows-based or custom GUIs with drag-and-drop menus. Multi-language support is crucial for global teams. Graphical programming—importing DXF files to auto-generate bend sequences—can slash setup from 30 minutes to 5.

- Input Options: Hybrid controls (touch, knobs, pedals) cater to different skill levels. USB ports for backups keep things flexible.

In my experience consulting fabricators, shops with user-friendly interfaces see 25% faster onboarding for new hires.

2. Programming Capabilities

Gone are the days of punch-card programming. Modern press brake controllers emphasize speed and error-proofing.

- Methods: Manual for pros, graphical offline for efficiency (CAD import via USB/Ethernet), or teach-in for custom jobs. Offline sims let you test without risking material.

- Storage and Management: Aim for 1GB+ capacity, with searchable libraries for 1,000+ programs. Tooling databases auto-adjust for punch/die wear.

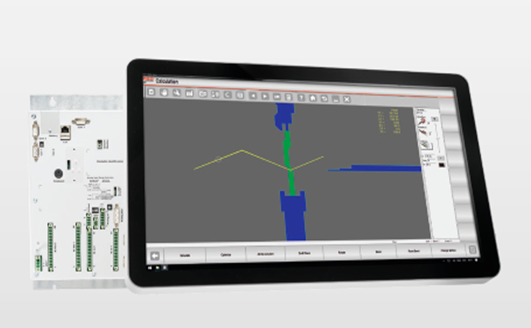

- Simulation and Collision Detection: Virtual previews flag interferences, reducing crashes by 90%. Advanced systems use 3D modeling for realistic renders.

For high-mix shops, this feature alone justifies the upgrade—think reducing programming errors from 15% to under 2%.

3. Control Accuracy and Compensation Features

Precision is where press brake systems shine or flop. Focus on feedback loops that adapt in real-time.

- Axis Control: Closed-loop servos for sub-micron positioning. Dynamic crowning adjusts Y-axes mid-bend to counter deflection—vital for spans over 3 meters.

- Backgauge Precision: X/Z/R axes should sync within 0.01mm, with speeds up to 500mm/s for quick repositions.

- Angle Measurement and Feedback: Laser or optical sensors (e.g., ±0.05° accuracy) enable closed-loop bending, auto-correcting springback. Mechanical gauges work for basics but lag in speed.

- Deflection Compensation: Adaptive algorithms use pressure/position data for per-bend tweaks. For thick aluminum, this maintains uniformity across batches.

Data from a 2023 AMADA user survey shows closed-loop systems improve repeatability by 40%, slashing rejects.

4. Automation and Integration Capabilities

Future-proof your setup with connectivity. Isolated machines are relics in Industry 4.0.

- Interfaces: Standard I/O for robots, conveyors; protocols like Profibus or EtherCAT for seamless integration.

- Networking: Ethernet for remote diagnostics, cloud uploads of production data. DNC (Direct Numerical Control) streams jobs wirelessly.

- Expandability: Modular designs let you add vision systems or AGVs later.

Shops integrating automation report 35% productivity gains, per McKinsey’s manufacturing reports.

5. Ease of Operation and Safety Features

Safety isn’t optional—it’s regulatory. A thoughtful press brake system weaves it in without slowing you down.

- Controls: Dual-palm buttons and light curtains for compliance. Programmable safety zones halt ops on anomalies.

- Quick Setup: Auto-calcs for pressure/speed based on material/tool data. One-touch homing for backgauges.

- Diagnostics: LED fault codes, predictive maintenance alerts (e.g., servo wear). Remote access cuts troubleshooting time.

Prioritizing these keeps OSHA fines at bay and morale high.

Overview of Major Brands and System Types

The market’s crowded, but leaders emerge based on tech and reliability. Here’s a breakdown by tier.

Tier | Brand Examples | Key Strengths | Price Range (USD) | Best For |

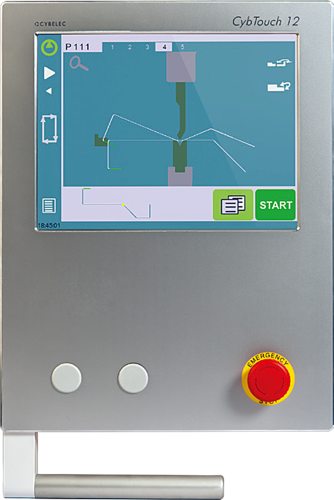

Premium | Cybelec (Cybelec CybTouch), Delem (DA-66T/69T) | Ultra-precise angle control, 3D simulation, seamless multi-axis | $20,000–$35,000 | Aerospace, automotive high-precision |

Premium | ESA (S.A.N.C.) | Hybrid/electric optimization, advanced servo integration | $18,000–$30,000 | Electric press upgrades |

Mid-Range | Beckhoff (TwinCAT), Bosch Rexroth (Cytronic) | Open architecture, customizable PLCs, strong networking | $10,000–$20,000 | Custom automation, mid-volume |

Mid-Range | WILA (Smart Tooling integration) | Tooling-focused, user-friendly for mixed batches | $8,000–$15,000 | General fabrication |

Entry-Level | Generic OEM (e.g., Chinese/ Taiwanese like CypCut), Basic Hydrapower | Simple CNC, manual overrides, cost-effective basics | $3,000–$8,000 | Low-volume, starter shops |

- Premium Brands: Cybelec’s stability shines in 24/7 ops; Delem’s DA series dominates with 50% market share (per 2024 SEMI reports) for its bend simulation wizardry.

- Mid-Range: Beckhoff’s PC-based openness lets coders tweak for IoT. Rexroth excels in rugged environments.

- Entry-Level: Solid for startups, but upgrade paths are limited. Domestic brands like those from Accurl offer value with growing software support.

Match to your scale: Premium for ROI in precision; entry for bootstraps.

Step-by-Step Guide to Selecting Your Press Brake Control System

Don’t wing it—follow this roadmap for a regret-free buy.

1.Define Your Requirements List: Jot down specs: Tolerances (±0.2° angles?), materials (mild steel up to 12mm?), volume (500 pcs/week?), budget ($15K max). List must-haves like 3D sim or robot I/O.

2.Research Models: Use tools like Ahrefs or Google for reviews. Shortlist 3–5: E.g., Delem for versatility, CypCut for budget. Download datasheets—cross-check axis specs.

3.Request Quotes and Proposals: Hit up distributors for tailored bids. Ask for ROI calcs (e.g., payback in 18 months via efficiency).

4.Review Demos and Videos: YouTube or supplier portals show real workflows. Watch for lag in touch response or sim accuracy.

5.Hands-On Testing (Essential): Visit trade shows like FABTECH or factories. Bring sample drawings—test a bend sequence. Measure outputs with calipers for true precision.

6.Vet Support and Service: Query response times (under 24hrs?), local techs, and update policies. Check forums like Practical Machinist for user gripes.

7.Weigh and Decide: Score options on a matrix: 40% performance, 20% ease, 20% cost, 10% support, 10% scalability.

Pull the trigger on the balanced winner.This process, honed from years advising shops, typically saves 15–20% on mismatched buys.

Key Considerations and Common Pitfalls

Even pros trip up—here’s how to sidestep.

- Beyond Price: A $4K system might nickel-and-dime you with $10K annual downtime. Calculate TCO: Initial + maintenance + training.

- Scalability: Will it handle tomorrow’s robot arm? Modular systems future-proof.

- Training Investment: Allocate 8–16 hours per operator. Intuitive UIs cut this, but budget $500–$1,000 for certs.

- Machine Matching: Stick to OEM-recommended pairings. Aftermarket? Test compatibility rigorously.

- True Metrics: Accuracy and Efficiency: Judge by output—consistent bends at speed—not specs. Aim for <5% variance in angle runs.

In essence, the best press brake system harmonizes your now with your next. High-precision demands scream for elites like Delem; everyday wins go to value mids like Beckhoff.

Empower Your Bends with the Right Choice

Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow.

Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.