How to Choose the Right Press Brake Tooling

Press brake tooling often referred to as bending machine dies, comes in various depths and configurations, tailored to different sheet materials. This variety drives a need for precise classification and selection. But what exactly determines which tooling suits a specific material? The logic lies in understanding material properties, bend requirements, and tooling parameters to ensure efficient, high-quality results.

In today’s fabrication shops, choosing the right press brake tooling isn’t just about getting the job done—it’s about optimizing productivity, minimizing waste, and achieving consistent bends. For instance, mismatched tooling can lead to defects like cracking, excessive springback, or uneven surfaces, costing time and money. This guide draws from industry best practices to help you navigate these choices. Whether you’re working with galvanized steel, stainless steel, aluminum, or plastic sheets, we’ll explore the key factors. By the end, you’ll have a clear framework for selecting press brake tooling that aligns with your project’s demands, ensuring bends that meet or exceed expectations.

Press brake tooling typically includes upper punches, lower dies, and holders. The upper punch applies force to shape the material against the lower die. With the right setup, you can handle everything from simple 90-degree bends to complex profiles. Factors like material thickness, tensile strength, and desired bend radius play crucial roles. According to fabrication experts, following rules like the “rule of eight”—where die openings are roughly eight times the material thickness—can prevent common pitfalls. Let’s dive into the components and how they fit together.

Press Brake Tooling Basics: Types and Parameters

To select the best press brake tooling, start by familiarizing yourself with its core components: punches (upper tools), dies (lower tools), and holders. Each part influences the bend’s accuracy, safety, and efficiency.

Press Brake Upper Punches: Variety for Versatile Applications

Upper punches come in several styles, each suited to specific bending needs. Common types include:

- Straight Sword Punches: Ideal for basic straight bends, these feature a sharp, straight edge and are great for high-precision work on thinner sheets.

- Gooseneck or Swan Neck Punches: These have a curved neck to clear flanges, making them perfect for U-shaped or channel bends without interference.

- Acute Angle Punches: With tips at 30 degrees or less, they’re used for sharp bends or when overbending to compensate for springback.

- Radius Punches: Rounded tips create smooth curves, essential for applications requiring large bend radii, like in aerospace parts.

- Offset or Joggle Punches: Designed for Z-shaped or offset bends, reducing the need for multiple passes.

When choosing a punch, consider the material’s ductility. For softer materials like aluminum, a larger tip radius prevents cracking. Punches should be precision-ground to tolerances around 0.0004 inches for accuracy, and segmented versions allow custom lengths, improving safety by reducing weight.

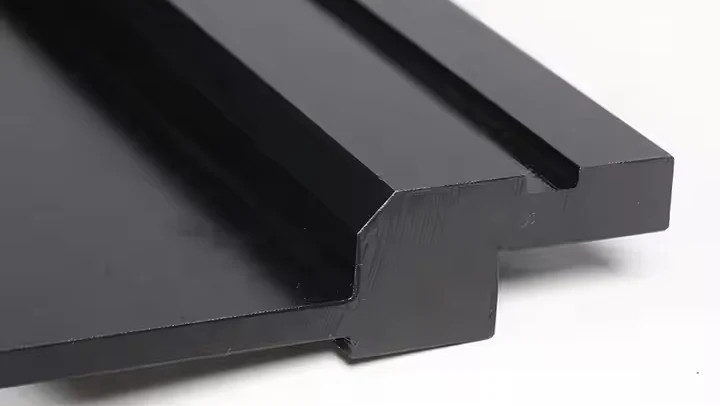

Press Brake Lower Dies: Foundation for Stable Bends

Lower dies support the material during bending. Key types include:

- Single V-Dies: Versatile with one V-groove; width varies based on material thickness.

- Multi-V Dies: Multiple grooves in one die block, allowing quick switches for different thicknesses without retooling.

- U-Shaped Dies: For channel forming in a single pass, saving time on repetitive jobs.

- Hemming Dies: Flatten acute bends, often with spring-loaded features to handle thicker materials.

Die openings (V-width) are critical—too narrow risks tool damage, too wide reduces precision. For most steels, aim for 6-10 times the material thickness.

Tool Holders: Ensuring Compatibility and Quick Changes

Holders secure punches and dies to the press brake ram and bed. Options include:

- Single-Slot Holders: Simple and cost-effective for basic setups.

- Double-Slot Holders: Offer low, medium, or high positions for flexibility with varying tool heights.

Modern systems like hydraulic or pneumatic clamping enable fast changes, cutting setup time by up to 50%. Always match holders to your machine’s tonnage and length to avoid overloads.

In practice, combining these components requires balancing factors like bend length and force distribution. For example, longer workpieces need uniform holder support to prevent deflection.

Material-Specific Guidelines for Press Brake Tooling Selection

Different materials demand tailored press brake tooling due to variations in hardness, elasticity, and formability. Here’s how to adapt for common types.

Press Brake Tooling for Galvanized Steel (Iron Sheets)

Galvanized steel, often used in construction, is moderately hard and prone to surface scratches. For 90-degree bends, use an 88-degree upper punch (or 86 degrees on CNC machines) to account for slight springback. Die groove radius (R) should be 0.5-0.8 mm, expandable to 1.0 mm if deeper impressions are needed. Tool hardness around HRC 47 ensures durability without excessive wear.

A practical rule: Die width = 5-6 times material thickness (minimum 4 times, maximum 8 times). This prevents cracking while extending tool life. For instance, on 2mm sheets, a 10-12mm V-die works well, distributing force evenly.

Press Brake Tooling for Stainless Steel

Stainless steel’s high tensile strength makes it challenging—it’s harder and more prone to springback. Opt for 83-degree or 76-degree punches for 90-degree bends. Keep die R under 0.5 mm for clean edges, but loosen to 1.0 mm for special impressions. Require HRC 49 hardness to resist abrasion.

Die width: 6-8 times thickness (minimum 5 times) to avoid rapid wear. For 3mm stainless, a 18-24mm V-die is ideal. Use hardened chromoly steel tools for longevity, and consider air bending to minimize tonnage—about 3-4 times higher than for mild steel.

Press Brake Tooling Tooling for Aluminum and Copper Alloys

Aluminum and copper are soft and ductile, risking tears if too much pressure is applied. Use 88-degree punches for straight 90-degree bends. Die R: 1.5-3.0 mm to protect surface finish. Hardness at HRC 47 suffices, as these materials don’t abrade tools aggressively.

Die width: 8-10 times thickness to reduce deformation. On 1mm aluminum, a 8-10mm V-die prevents cracks. Radius punches help for curved profiles, and nylon inserts can eliminate marks on polished surfaces.

Material | Recommended Punch Angle (for 90° Bend) | Die R (mm) | Hardness (HRC) | Die Width Multiplier |

Galvanized Steel | 88° (86° CNC) | 0.5-1.0 | 47 | 5-6x Thickness |

Stainless Steel | 83° or 76° | <0.5 (up to 1.0 special) | 49 | 6-8x Thickness |

Aluminum/Copper | 88° | 1.5-3.0 | 47 | 8-10x Thickness |

This table summarizes quick-reference guidelines, but always test on scrap for fine-tuning.

Key Parameters in Press Brake Tooling Selection

Beyond material, focus on bend angles, die openings, and hardness for optimal results.

Bend Angles and Tool Angles

The punch angle must compensate for springback—materials “bounce back” after bending. For stainless, overbend by 2-5 degrees. Acute punches handle <90° angles, while standard ones suit broader needs. Ensure the angle aligns with the die; mismatch causes uneven bends.

Die Openings: V-Groove Width and Radius (R)

V-width follows the rule of eight: 8x material thickness for mild steel, adjusted for others (6x for thin, 10x for thick). Narrower openings increase tonnage but improve precision; wider reduce force but risk inaccuracy. R affects edge quality—smaller for sharp edges, larger for soft materials to avoid marks.

Tonnage calculation: Use charts where force (tons/ft) = (Material thickness² x Tensile strength) / Die width. Stay under machine limits to prevent damage.

Tool Hardness and Durability

Hardness (HRC) resists wear: 47-49 for metals, lower for plastics. Materials like chromoly steel offer corrosion resistance. Precision tolerances (0.0004 in.) ensure repeatability. Segmented tools add versatility, allowing custom setups without full replacements.

Addressing Workpiece Interference and Special Considerations

Workpiece features like holes, nuts, or flanges can interfere. For avoidance:

- V-Slot Selection: For thickness ≤4mm, V-width ≤24mm; ≥4mm, ≥32mm. Minimum 4x thickness for 90° bends to avoid scrap.

- Interference Avoidance: Choose gooseneck punches for flanges or bent knives for offsets. If protrusions exist, select dies with clearances or use rocker dies to prevent deformation near cutouts.

Common error: Ignoring minimum flange length (at least 77% of V-width). Test setups on prototypes.

Special Press Brake Tooling Options

For unique shapes, consider:

- Segmented or Adjustable Dies: For step bends, adjust fillers to control dimensions.

- Custom Tools: Based on workpiece size, safety height, and pressure. Examples include corrugating dies for textured surfaces or hemming sets for flat seams.

Factors: Machine pressure, part appearance, and performance. These reduce passes, boosting efficiency.

Real-World Examples and Maintenance Tips

In a bridge fabrication project using galvanized steel, selecting an 88° punch with 0.8mm R die yielded perfect 90° bends without cracks. For aerospace aluminum, radius tools prevented surface flaws.

Maintenance: Clean tools daily with alcohol, store vertically in rust-free cabinets, lubricate, and inspect for wear. Proper care extends life by 20-30%.

Conclusion: Mastering Press Brake Tooling for Superior Results

Selecting the right press brake tooling boils down to matching materials, parameters, and project needs. By prioritizing precision, versatility, and safety, you’ll achieve efficient bends that stand out. Experiment, consult experts, and refine your approach—your fabrication quality will thank you.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.