How to Correct CNC Press Brake Angles

In the world of metal fabrication, achieving consistent press brake angles is crucial for producing high-quality parts. If you’re dealing with a CNC press brake where the angles vary across the workpiece—such as one end being sharper than the other—it can lead to wasted materials, rework, and production delays. This guide addresses the user intent behind searches like “how to fix inconsistent angles on CNC press brake” by providing in-depth causes, practical solutions, and expert tips. Drawing from industry standards and real-world troubleshooting, we’ll help you restore accuracy to your CNC press brake operations.

As a specialist in CNC machinery with over a decade of experience in sheet metal processing, I’ve seen these issues arise frequently. Backed by references from reliable sources like The Fabricator and CAMT Machine Tool, this article offers actionable insights to enhance your bending precision.

Causes of CNC Press Brake Angles Problem

CNC Press Brake Inconsistent angles often stem from a mix of mechanical, operational, and environmental factors. These problems can make the bend vary along the length of the sheet metal, resulting in parts that don’t meet tolerances. Below, we break down the most common causes, expanded with insights from fabrication experts and technical handbooks.

1. Mechanical Equipment Issues For Press Brake Angles

The core structure of your CNC press brake plays a pivotal role in bend consistency. Problems here are among the top culprits for angle variations.

Uneven Worktable Base: If the base of the press brake isn’t perfectly level, it can cause deflection under load, leading to uneven pressure distribution. For instance, a slight tilt might result in one side bending more than the other.

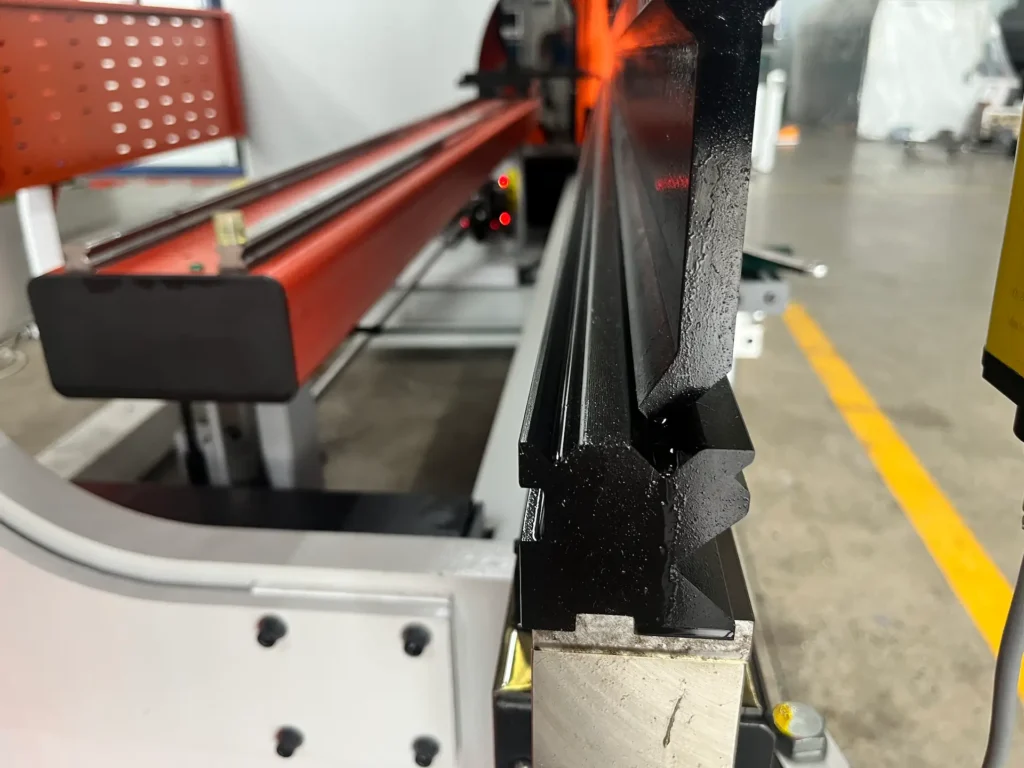

Damaged or Worn Clamps and Tooling: Worn punches or dies can slip or misalign during operation. According to troubleshooting forums, even minor wear on tooling can amplify angle inconsistencies, especially in high-volume production.

Additional Factors: Misaligned beams or loose bolts in the frame can exacerbate this. In one case study from Amada machines, loose connections were found to cause up to 2-3 degree variations in bends.

2. Operator Inexperience or Improper Technique For Press Brake Angles

Human error is a frequent issue, particularly in setups where precision adjustments are overlooked.

Inaccurate Adjustments and Measurements: Improper setup of clamps, backgauges, or punch depths can lead to inconsistent results. For example, failing to measure material thickness accurately might cause over- or under-bending on one side.

Punch Angle and Positioning Errors: Operators new to CNC press brakes might not account for material springback—the tendency of metal to revert slightly after bending—which varies by alloy and thickness.

Real-World Insight: Discussions on CNCZone highlight how inconsistent ram leveling due to operator oversight can produce bends that vary by several degrees from one part to the next.

3. Unstable Support Points Under the Worktable For Press Brake Angles

Stability is key during high-pressure bending operations.

Uneven Footings or Supports: If the machine’s legs or base supports are unbalanced, vibrations or shifts during operation can distort angles. This is especially problematic on uneven factory floors.

Load Distribution Problems: Without proper support, the worktable might bow slightly under tonnage, leading to pressure imbalances. Industry reports note that this can cause up to 1-2mm deviations in parallelism, directly affecting bend angles.

Other contributing factors include material inconsistencies (e.g., varying sheet thickness) and environmental issues like temperature fluctuations, which can alter metal properties and lead to unpredictable bends.

Correct Adjustment Methods for CNC Press Brake Angles

Once you’ve identified potential causes, systematic troubleshooting and adjustments are essential. Start with a visual inspection and use tools like dial indicators or pressure gauges for precision. Below are proven methods, drawn from manufacturer guidelines and expert videos, to restore uniformity to your CNC press brake bends.

1. Adjust the Bending Fixtures For Press Brake Angles

Proper fixture setup ensures even clamping without distortion.

Steps: Loosen the clamps and realign them to the material. Check for play—if too loose, the workpiece may shift; if too tight, it could create uneven tension. Use a torque wrench for consistent tightening.

Tips for Precision: Aim for a clamp pressure that matches the material’s yield strength. In practice, adjusting fixtures has resolved up to 80% of angle issues in some workshops, per Reddit discussions on press brakes.

2. Check and Maintain Mechanical Equipment For Press Brake Angles

Regular inspections prevent small issues from becoming major problems.

Inspection Process: Examine the frame for loose bolts, check linkages for wear, and ensure the base is level using a spirit level or laser aligner. Replace damaged parts promptly.

Advanced Checks: Verify ram parallelism with a calibration rod. If deviations exceed 0.02mm/m, recalibrate as per ISO standards.

3. Calibrate the Punch Return Position For Press Brake Angles

The punch (or top tool) must return accurately to maintain consistent depths.

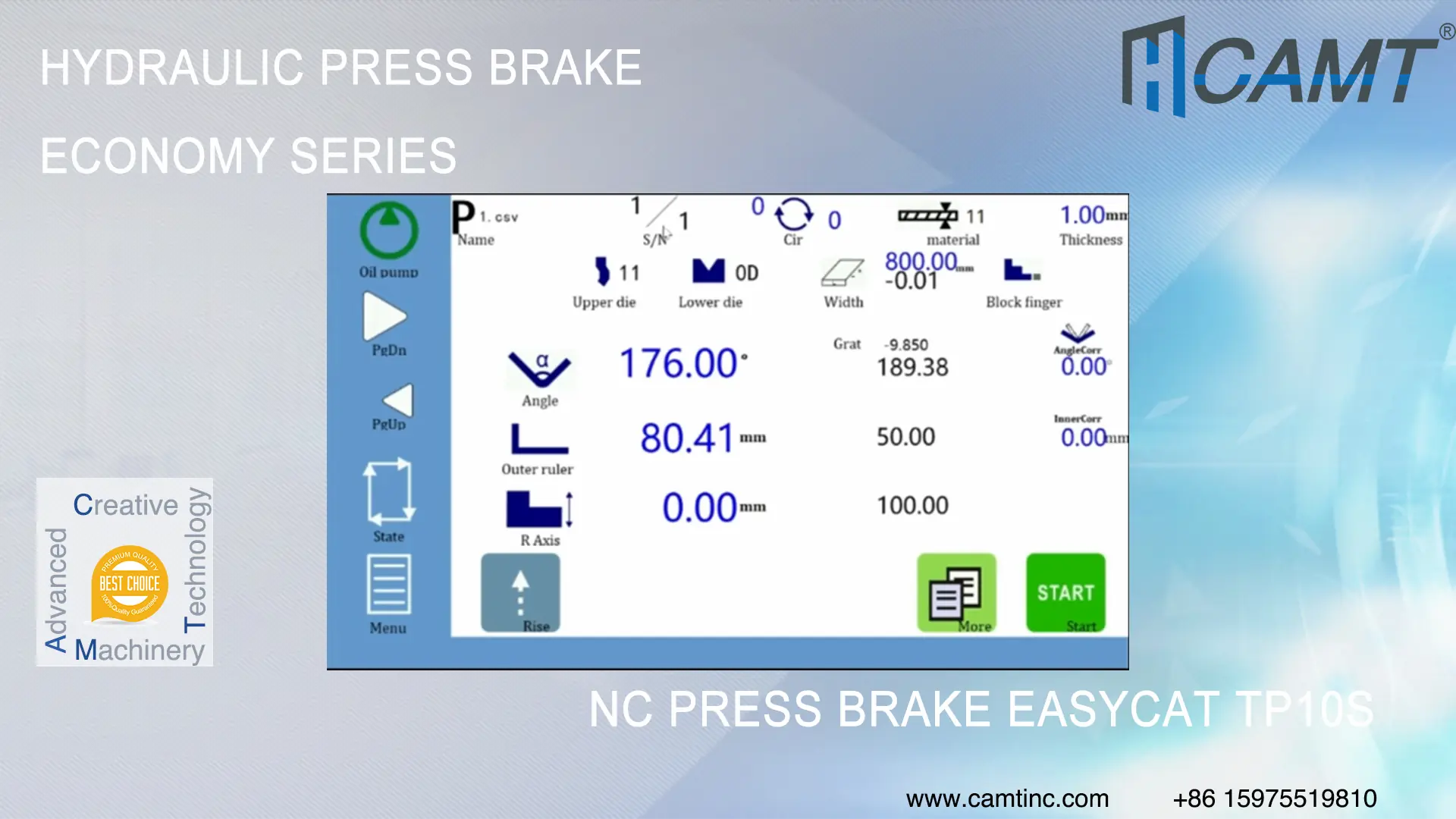

Calibration Steps: Adjust the backgauge and punch angle based on test bends. Use the CNC controller to fine-tune return positions, accounting for springback—often 1-3 degrees for mild steel.

4. Inspect and Stabilize the Worktable For Press Brake Angles

A stable platform is non-negotiable for accurate bending.

Methods: Check support points for balance and add shims if needed to level the table. Test under load to confirm no deflection.

Preventive Measures: Install anti-vibration pads and perform monthly checks. This can reduce inconsistencies by ensuring even pressure across the bed.

In summary, addressing inconsistent angles on a CNC press brake requires methodical checks tailored to your setup. Proper operation not only fixes immediate issues but also ensures long-term reliability and high-quality outputs.

Summary and Additional Tips About Press Brake Angles

To wrap up, here are targeted tips for common root causes, supported by technical standards like the Sheet Metal Processing Handbook and ISO 9001.

1.Mold Installation Problems

Issue: Upper and lower molds not centered; offsets over 0.1mm can skew angles.

Solution: Measure centerline with a dial indicator and adjust to ≤0.05mm deviation for optimal alignment.

2.Slider Parallelism Deviation

Issue: Slider not parallel to the worktable, causing uneven pressure (standard: ≤0.02mm/m error across full length).

Steps: Shut off the hydraulic pump, place a calibration rod on the table, and manually adjust slider screws until gaps are uniform at both ends.

3.Hydraulic System Pressure Imbalance

Issue: Pressure differences exceeding 5% between cylinders lead to inconsistent forces.

Detection and Fix: Attach pressure gauges to cylinder test ports; under no load, ensure difference ≤2MPa. Adjust valves per ISO 9001 guidelines for balanced output.

By implementing these strategies, you’ll minimize downtime and improve bend accuracy on your CNC press brake. For persistent issues, consult a certified technician or refer to your machine’s manual.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.