How to Properly Install a Press Brake Machine

Understanding the Importance of Proper Press Brake Installation

A press brake machine is a precision forming machine, and its installation quality directly influences bending accuracy, repeatability, and long-term mechanical stability. In real production environments, many performance issues that appear to be related to machine quality are actually caused by improper installation. For this reason, installation should be approached as a technical process rather than a simple positioning task.

Correct installation minimizes internal stress within the machine frame, ensures even force distribution during bending, and provides a stable base for hydraulic and electrical systems. Especially for CNC press brakes, even small installation errors can accumulate and affect final bending results.

Foundation Preparation and Machine Positioning

Concrete Foundation Requirements

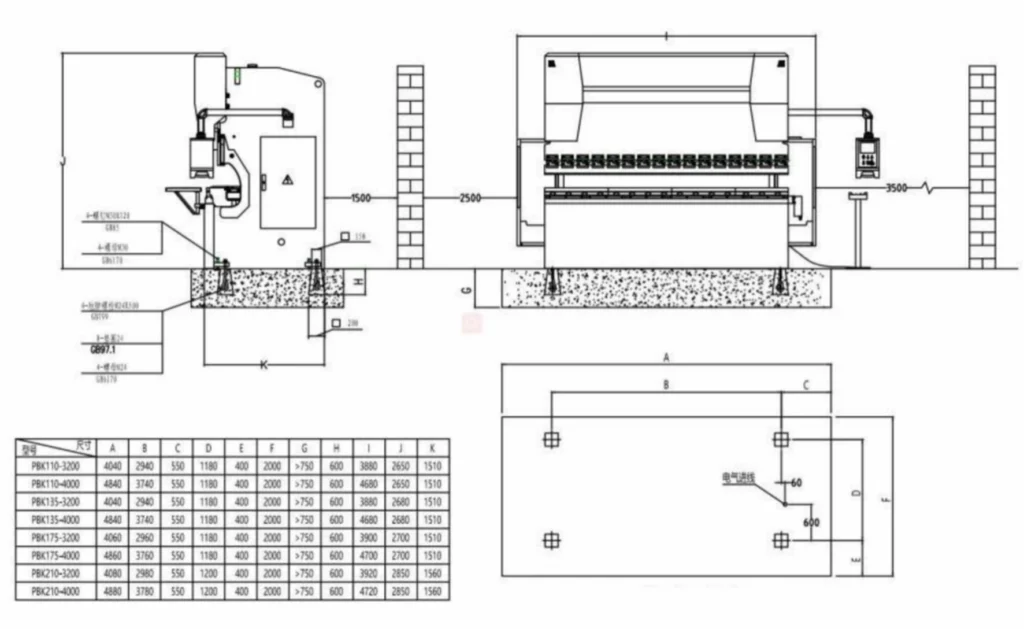

Before the press brake machine arrives at the installation site, a suitable concrete foundation should already be in place. In practice, the foundation is normally poured at least ten days in advance, allowing the concrete sufficient time to cure and reach a stable strength level. A properly cured foundation helps absorb vibration and prevents gradual settlement during long-term operation.

Once the machine is positioned, anchor bolts are fixed using a second cement grouting process. It is important to ensure that only the four base plates of the machine frame make contact with the foundation. Any unintended contact between other frame sections and the ground may introduce internal stress, which can lead to accuracy loss over time.

Precision Leveling of the Press Brake Machine

Transverse Leveling and Structural Stability

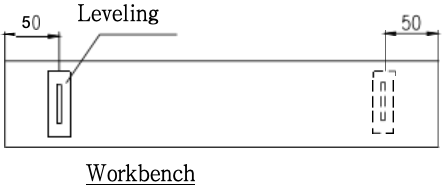

After the cement grout has fully solidified, the leveling process can begin. Transverse leveling focuses on the left–right alignment of the machine. A precision level is placed close to both ends of the worktable, typically about 50 millimeters from the edges. By adjusting the anchor bolt screws, the transverse accuracy is controlled within 0.2 millimeters per 1000 millimeters. This step ensures that bending forces are evenly distributed across the working width of the machine.

Longitudinal Leveling and Worktable Crowning

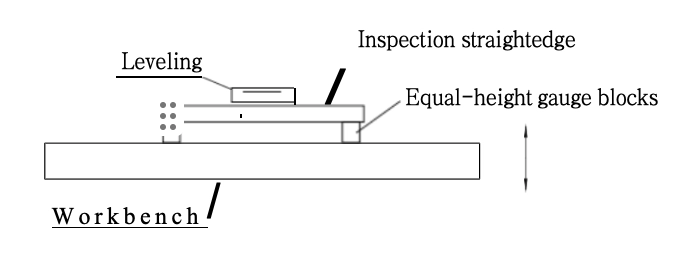

Longitudinal leveling requires more attention due to the crowning design commonly applied to press brake worktables. This crowning compensates for deflection during bending, but it also means that the level cannot be placed directly on the table surface. Instead, equal-height gauge blocks are positioned symmetrically on the worktable, with a straight inspection ruler resting on top. The level is then placed at the center of the ruler to obtain an accurate reading.

By carefully adjusting the anchor bolts, the longitudinal leveling accuracy is brought within 0.2 millimeters per 1000 millimeters. After all anchor bolts are tightened, the accuracy should be checked again to ensure that no deviation has occurred. During this process, all measuring surfaces must be kept clean and free from oil or dust to avoid false readings.

Hydraulic Oil System Setup and Management

Cleaning the Hydraulic Oil Tank

The hydraulic system is the core power source of a press brake machine, and oil cleanliness plays a decisive role in its reliability. Before filling new hydraulic oil, the oil tank must be thoroughly cleaned. This involves removing the tank cover, wiping the interior surfaces with a lint-free towel, and flushing the tank with clean kerosene or gasoline. Cotton waste should not be used, as fibers may remain inside the system and contaminate valves or pumps.

Special attention should be given to corners, weld seams, and areas that are difficult to reach. In some cases, flour dough can be used to collect fine particles from weld seams. The tank should be completely clean and dry before refitting the cover.

Selecting and Filling the Correct Hydraulic Oil

Choosing the right hydraulic oil depends on operating pressure, ambient temperature, and working speed. Under normal conditions, ISO VG46 anti-wear hydraulic oil is recommended, as it provides a balanced viscosity at 40°C. In colder environments where temperatures remain below 5°C for long periods, ISO VG32 may be more suitable to ensure smooth startup.

When filling the oil, only clean and filtered hydraulic oil should be used. Oil is typically added through the air filter opening on the tank cover. When the ram is positioned at top dead center, the oil level should reach approximately 80 to 90 percent of the sight glass capacity. Under normal operating conditions, oil temperature should be kept below 70°C. In high-temperature environments, additional cooling measures may be required.

Electrical Connection and Power Supply Requirements

Power Supply, Grounding, and Safety Checks

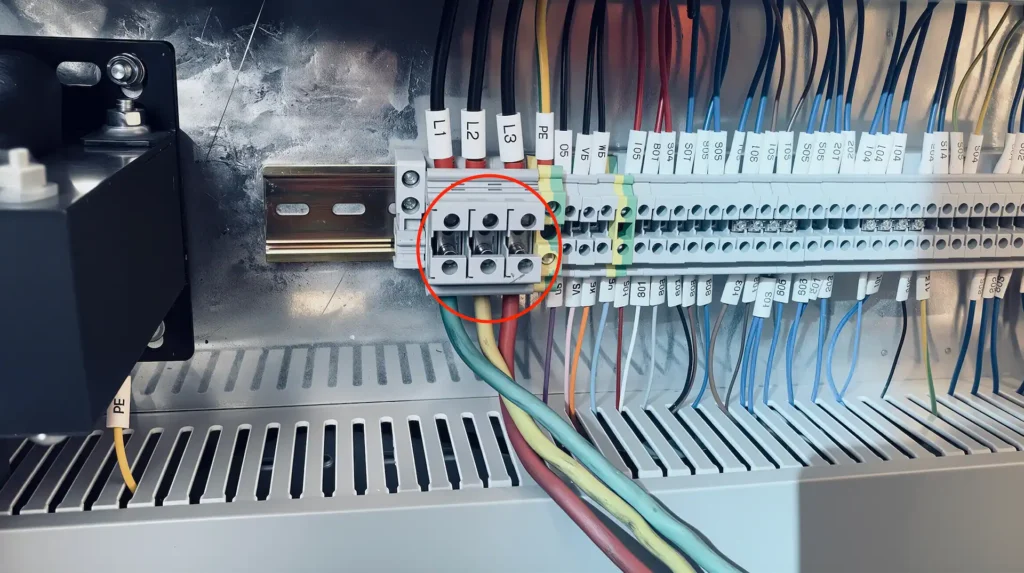

Most press brake machines operate on a three-phase power supply, and electrical wiring must comply with applicable safety regulations. The power cable cross-section should be selected to limit voltage drop and ensure stable motor operation. Proper grounding is essential to protect both operators and sensitive electronic components from electrical faults.

After connecting the power supply, the machine should be started briefly to check the rotation direction of the hydraulic pump motor. The rotation must match the arrow marked on the pump housing. If the direction is incorrect, swapping any two phases of the three-phase supply will usually resolve the issue.

Final Inspection Before Production Operation

Before the press brake machine is put into regular production, a final inspection should be carried out. This includes verifying leveling accuracy, confirming hydraulic oil level and temperature, running the machine under no-load conditions, and checking all safety functions. These steps help ensure stable operation, consistent bending accuracy, and a long service life for the machine.

Schedule interruptions to prevent overwarming—power off after extended performances to restore capability. This basic action limits instability, lessening burrs from compromised mirrors.

- Comply with functional cycle suggestions.

- Observe heat meters.

- Reactivate after chilling for uniform results.

Frequently Asked Questions About Press Brake Installation

How long should the foundation cure before installing a press brake?

The foundation should cure for at least ten days before installation. This allows the concrete to reach sufficient strength and prevents later settlement that could affect machine accuracy.

Why does press brake leveling influence bending accuracy?

Proper leveling ensures that bending forces are evenly distributed along the worktable. Poor leveling can cause uneven angles, reduced repeatability, and long-term mechanical stress.

Why is longitudinal leveling different from transverse leveling?

Press brake worktables are usually crowned to compensate for deflection. Because of this design, longitudinal leveling must be performed using gauge blocks and a straight ruler rather than placing the level directly on the table.

What hydraulic oil is recommended for press brake machines?

ISO VG46 anti-wear hydraulic oil is recommended for most operating conditions. In colder environments, ISO VG32 may be used to improve oil flow during startup.

Can a press brake be used immediately after installation?

No. The machine should undergo leveling verification, hydraulic system checks, electrical inspection, and no-load testing before entering normal production.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.