Crowning System

CAMT®️Mechanical Compensation in Press Brakes: Precision, Efficiency, and Cost-Effectiveness

CAMT® Automatic Defelection Compensation:

Ensures consistent bending angles by counteracting ram and worktable deformation, ideal for long workpieces and high-accuracy tasks.

Simpler design with lower maintenance costs compared to hydraulic or CNC compensation, suitable for budget-conscious operations.

Soft stop mode

- Automated compensation minimizes setup time, boosting production efficiency.

- Automatic systems integrated with CNC reduce operator skill requirements.

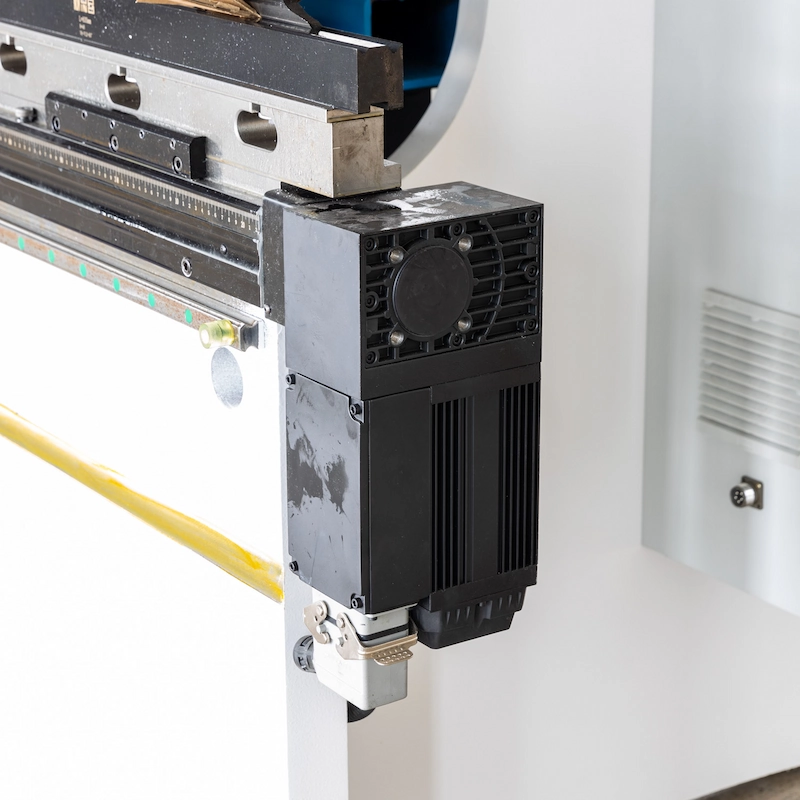

- Mechanic Compensation.

- Benefits of Mechanical Compensation with Precise Effectiveness and Multi-Point Crowning.

- Reduces Deformation: Counteracts worktable and slider distortion from applied forces, ensuring consistent bending angles and enhanced machining accuracy, especially for long and varied workpieces.

Improves Precision: Multi-point mechanical crowning allows independent adjustments across the worktable’s length, precisely managing deformation in each section for superior straightness and uniformity in extended workpieces.

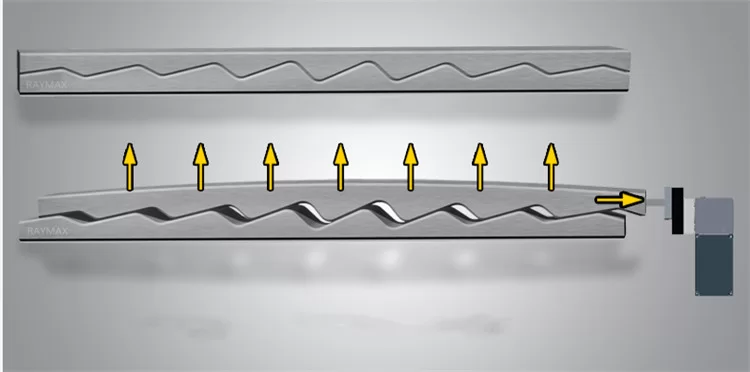

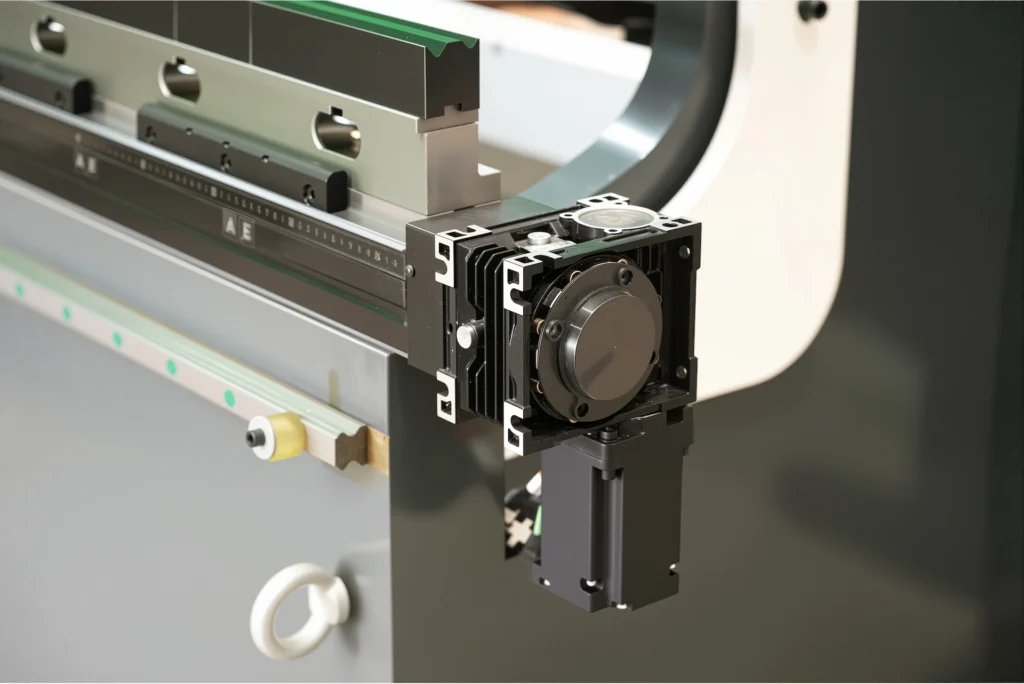

Benefits of Electric Motorized Crowning

- Addresses bending or sagging in the worktable and slider caused by applied forces, particularly at the center, ensuring consistent results.

- Utilizes a system of movable wedges or supports to pre-adjust or dynamically alter the worktable’s shape for optimal performance.

Automatically or manually adjusts based on material thickness, length, and bending force to maintain precision.

- Maintains a consistent gap between upper and lower dies, delivering even bending angles across the entire workpiece.

- Utilizes a system of movable wedges or supports to pre-adjust or dynamically alter the worktable’s shape for optimal performance.

- Automatically or manually adjusts based on material thickness, length, and bending force to maintain precision.

- Maintains a consistent gap between upper and lower dies, delivering even bending angles across the entire workpiece.