CAMT-INNOVATION MEETS PRECISION

Popular Synchronous Press Brake Smart 3-4 Axis

Max. Running Speed 120M/MIN

Popular Synchronous Press Brake Smart 3-4 Axis

CAMT Popular CNC Bending Solution

Preferential Quality with Less Error Rate

Faster Working Efficiency.

Eco-friendly;40% Energy Saved.

Overseas After-Service Support Bending System

CAMT adopts rack and pinion transmission structure, standard manual clamping chuck, push-type pipe cutting method, can be used for general sheet metal cutting and common square tube, round tube, rectangular tube cutting.

55X55

55X55

Supports one-button color switching, approximately 1024*768 resolution

Utilizes platform industrial-grade display

Newly developed industrial-grade MEC4 embedded version, customizable

Supports multiple expansion options: color, machine motion control, USB port (image loading), CAN expansion, etc. Optional features.

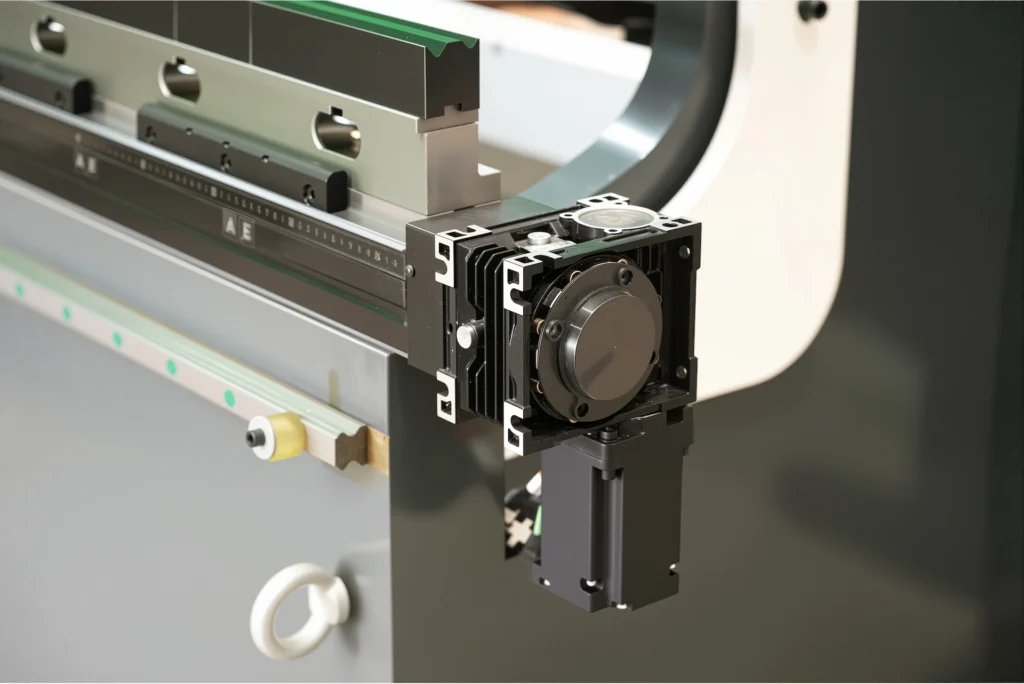

Imported Italy GIVI Maganetic Misure

- All-In-One Effective Servo Motor

- Graphite Self-lubricating Copper Plate

- Safety France Schneider Electric System Components

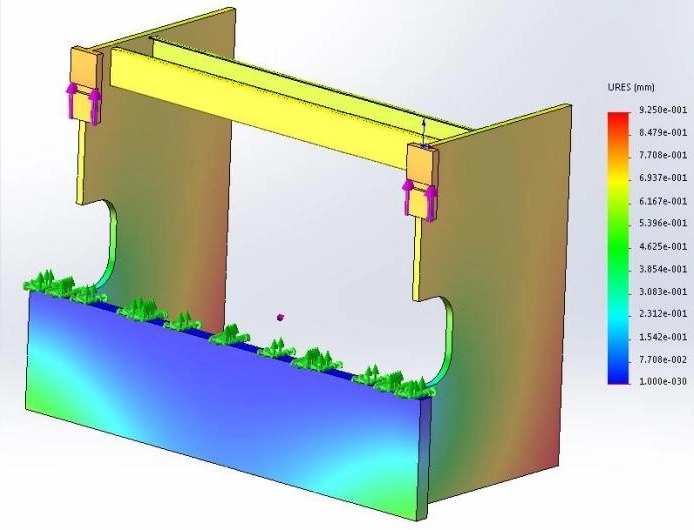

- FEA & Stress Analysis of Press Brake

- Stress Analysis & Finite Element Analysis

- CAMT FEA plays a pivotal role by optimizing structures through stress distribution analysis to identify and reinforce high-stress areas, enhancing strength while minimizing material waste; verifying performance by predicting deformation under extreme loads (e.g., 600 tons) to ensure precision and stability for Y1/Y2 synchronization; assessing safety by evaluating stress concentration to mitigate fatigue or fracture risks for long-term reliability; and conducting dynamic analysis to simulate transient loads and vibrations in complex scenarios like tandem bending or high-speed operations, optimizing servo motor response and overall machine stability.

- DELEM DA66T Touch 2D Graphical Control

- 17" high resolution colour TFT

- 2D graphical touch screen programming mode

3D visualisation in simulation and production

Full Windows application suite

Up to EN 12622 meet legal requirements and avoid liability issues.

Enabling safe and efficient workflows by detecting intrusions in real time

- High Sensitivity and Accuracy

- Flexibility for Diverse Applications

- High safety standards, Ahieve SIL 3 (Safety Integrity Level 3)

- Supporting efficient production

- Precise Effectiveness & Muti-Point Crowning of Press Brake Machine

- Mitigates deformations in the worktable and slider due to applied forces, ensuring uniform bending angles and improved machining precision, particularly for long and diverse workpieces. Multi-point mechanical compensation, with independently adjustable points along the worktable’s length, precisely controls deformation in each segment, significantly enhancing straightness and consistency for extended workpieces.

High Durability: High-quality steel and undergoes meticulous processing, ensuring exceptional durability, strong compressive strength, and substantial weight to withstand heavy-duty operations.

Simplified Operation: Effectively reducing on-site setup time and extending the lifespan of components.

- ESA S660W CNC System

- “A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

- Ease of Maintenance: Convenience, offering easy maintenance, user-friendly operation, and a longer service life, minimizing on-site labor and manpower requirements.

- Tool and die holders’ management.

- 19 inch LCD touch screen (Capacitive).

- Stander to 4 axis, can up to 156 axis max.

- ESA S675W CNC System

- 21 inch LCD touch screen (Capacitive)

Tandem machine management(option, can up to 4 machines)

ESA S650W 2D Graphical CNC System

- No limit in both performances and flexibility.

- "The powerful built-in Pc allows having on the machine a real 3D cad cam (metallix, radan, esa)

- Finger-tip work piece design.

- Direct import of tools shapes (.dxf files) and management of tool library.

- Tool and die holders management.

- Angle measurement and correction with all existing devices is available.

breadcrumbs

hybrid servo eco system function

- 高精度なバックゲージ位置決めを可能にし、通常±0.01mmの精度で、高精度な曲げ加工のニーズに適しています。.

- バックゲージ速度は最大300 mm/sで、高精度な位置決め精度を実現します。.

- 迅速な応答時間により、バックゲージ位置の素早い調整が可能となり、生産効率を向上させます。.

- 長時間の高負荷条件下でも一貫した性能を発揮し、エラーを最小限に抑えます。.

- 多軸(X、R)連動により、複雑なワークピースの加工要件に柔軟に対応し、加工の汎用性を高めます。.

- 自動プログラミングと操作により、手動介入を減らし、大量生産に適しています。.

GIVI MISURE

イタリア製輸入マグネットルーラー - 精密な位置決めとタイムリーな反応

Compared to traditional models, reduces bending pressure by 10%

- 曲げ加工中の怪我を効果的に防止します。.

- EN 12622に準拠し、法的要件を満たし、賠償責任問題を回避します。.

- リアルタイムで侵入を検知することで、安全かつ効率的なワークフローを可能にします。

- 高感度と高精度

- 多様なアプリケーションへの柔軟性

- 高い安全基準、SIL 3(安全度水準3)を達成

- 効率的な生産をサポート

Improves Precision: Multi-point mechanical crowning allows independent adjustments across the worktable’s length, precisely managing deformation in each section for superior straightness and uniformity in extended workpieces.

Precise Effectiveness & Muti-Point Crowning of Press Brake Machine

China Strict Inspection Hydraulic Press Brake Oil Cylinder

- High Durability: High-quality steel and undergoes meticulous processing, ensuring exceptional durability, strong compressive strength, and substantial weight to withstand heavy-duty operations.

- Simplified Operation: Effectively reducing on-site setup time and extending the lifespan of components.

- Comprehensive Capabilities: Robust quality control and inspection system during production, ensuring that finished workpieces meet standards while maintaining complete functionality and smooth operation.

- Structural Compactness: Compact yet sturdy design, with a tight structure that ensures efficient storage and operation, enhancing support effectiveness.

- Ease of Maintenance: Convenience, offering easy maintenance, user-friendly operation, and a longer service life, minimizing on-site labor and manpower requirements.

Bending Tool & Fast Clamping:

Soft stop mode

- Superior Tooling Durability: Crafted from 42CrMo steel, the tooling undergoes high-temperature forging and quenching to achieve a hardness of 47-49HRC, delivering exceptional bending performance and resilience across diverse working conditions.

- Enhanced Precision: The 835mm segmented CNC concentric mold design ensures precise centering, improving accuracy for complex bending tasks.

- Efficient Tool Changes: Features a quick-clamp system for rapid tool replacement, supporting both front (vertical) and rear (horizontal) configurations, increasing operational efficiency and reducing labor requirements.

- Versatile Compatibility: Designed to seamlessly accommodate European-style punches without modification, offering flexibility for various applications.

CAMT Itergral Hydraulic System

Advanced Hybrid Servo ECO Technology for Press Brake Machine

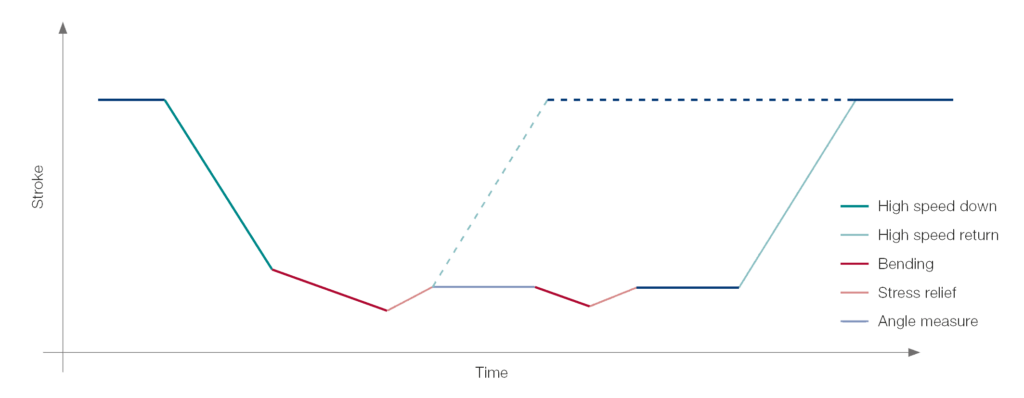

Soft stop mode

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.