Laser Cutting Burr Problems and Solutions: Strategies for Achieving Clean Edges on Your Laser Cutting Machine

Significant Challenges Posed by Burrs in Laser Cutting Processes

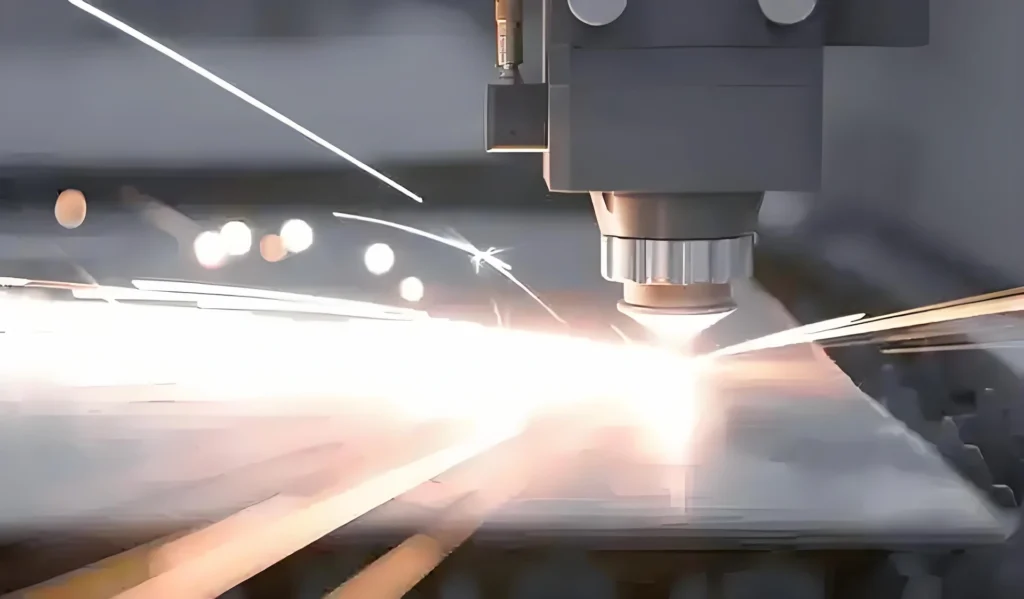

Laser cutting machines have become vital assets in metal fabrication workshops, enabling swift, precise shaping of materials including carbon steel, stainless steel, and aluminum alloys. These devices minimize scrap and support intricate designs, contributing to faster production and better overall finishes. However, operators frequently encounter a persistent issue: the development of burrs on the perimeters of cut items. These laser cutting burrs—small, irregular metal fragments or ridges—can detract from the workpiece’s smoothness and usability.

The implications of laser cutting burr problems are extensive and impactful. In high-stakes industries like automotive manufacturing, medical equipment production, and structural engineering, burrs can interfere with part interlocking, promote rust initiation, or even create electrical hazards in conductive assemblies. They also elevate the potential for workplace accidents due to abrasive surfaces and drive up operational expenses via necessary follow-up treatments such as sanding or chemical etching. Reports from fabrication studies suggest that ongoing burr concerns can boost secondary processing costs by 20-35%, slowing down assembly lines and affecting profit margins. Commonly, users attribute these flaws to inherent machine shortcomings, yet investigations often point to adjustable elements like process variables or routine care deficiencies.

This comprehensive guide analyzes the five main origins of burrs in laser cutting machines and presents effective countermeasures. By applying these approaches, you can secure refined edges, optimize throughput, and maintain elevated benchmarks. Furthermore, we’ll review how sophisticated models from CAMT incorporate built-in mechanisms to forestall these difficulties, yielding dependable, superior performance.

Identifying the Key Origins of Laser Cutting Burrs

Burrs arise when liquefied metal within the cut groove fails to disperse entirely, solidifying into undesirable extensions. This results from disruptions in energy distribution, airflow efficiency, or apparatus reliability. Drawing from metalworking investigations, these primary sources are outlined below, supported by insights from various operational contexts.

Inadequate Auxiliary Gas Quality

A often-neglected factor in laser cutting burr creation is the diminished quality of the supporting gas, such as oxygen or helium, which removes fused remnants from the pathway. Impurities like vapors or debris hinder this removal, permitting leftovers to adhere and set.

In brass processing, polluted gas could lead to tarnishing, generating erratic margins. Measurements indicate that gas dependability dropping under 99.6% may elevate burr prominence by 35%, requiring further polishing steps. This worsening heightens in sustained runs without oversight.

Excessively Low Cutting Velocity

Several technicians believe decelerating the slice improves refinement, but it commonly heightens burrs. Lowered velocity increases heat concentration, super-liquefying the foundation and overloading the gas stream, producing bonded residuals.

For titanium sheets, cutting velocity by a fifth (from usual 2-6 m/min for 4mm width) might quintuple burr occurrences, as prolonged warmth pulls liquid back into the crevice. This oversight is widespread among novice practitioners favoring prudence over pace.

Insufficient Laser Intensity

The laser’s force needs to correspond with the foundation’s width and makeup for complete dissipation. Lacking force causes fractional fusion, yielding extra leftovers that don’t scatter, freezing as burrs—especially on bulkier substances where “tug streaks” appear on the lower side.

Trying to divide 12mm bronze with suboptimal setups (e.g., 2.5kW instead of 5kW) initiates fractional passage and considerable buildups. Standards recommend no less than 70-80% dissipation for immaculate margins, preventing accumulation.

Prolonged Non-Stop Device Functioning

Although sturdy, laser cutting machines weaken under incessant strain. Overheating compromises parts like mirrors and propulsion units, generating inconsistent ray delivery and augmented burrs.

In round-the-clock settings, burr levels could climb 12-22% after 7-9 hours without halts, due to warmth-caused misalignment spreading force. This “apparatus tiredness” echoes staff burnout, emphasizing arranged breaks.

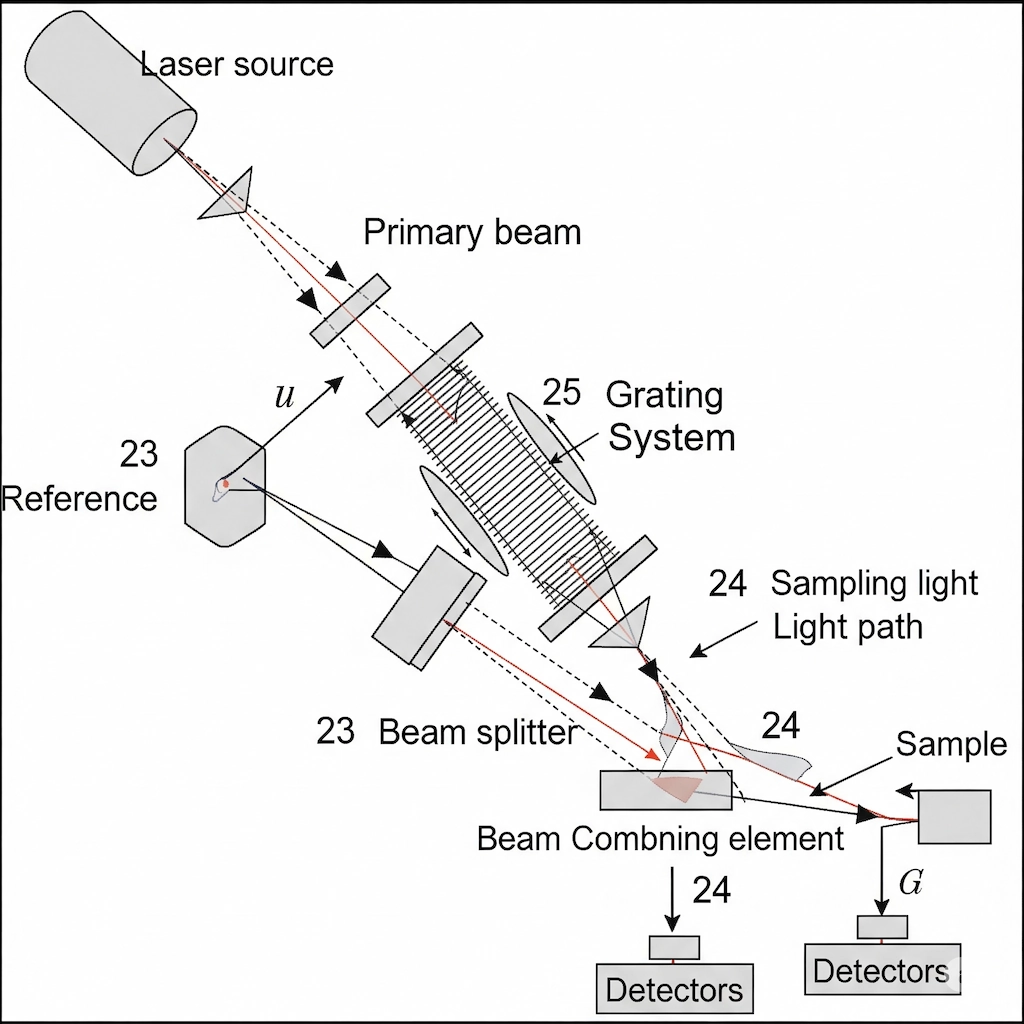

Laser Beam Convergence Offset

Accurate ray convergence on the foundation plane is crucial for force intensity. Displacements—even slight, such as 0.4mm—scatter the beam, producing uneven warming, fractional dissipation, and poor leftover ejection.

For fine laminates, these offsets change fluid slices into burr-filled ones, typically from arrangement mistakes or foundation bending. Exact convergence maximizes force compactness, enabling proficient fused debris evacuation.

Origin of Laser Cutting

| Origin of Laser Cutting Burr | Noticeable Indicators | Effects on Production |

|---|---|---|

| Inadequate Gas Quality | Tarnishing on margins, leftover buildup | 35% increase in burr prominence, higher polishing costs |

| Low Cutting Velocity | Super-fused groove, residual bonding | Quintupled burr levels, 20% throughput decline |

| Insufficient Intensity | Fractional passage, tug streaks | Considerable buildups, interlocking issues |

| Prolonged Functioning | Inconsistent slices after hours | 12-22% flaw rise, apparatus interruptions |

| Convergence Offset | Uneven margins, feeble ejection | Reliability loss, accident risks |

Reliable Approaches to Remove Laser Cutting Burrs

Eliminating burrs involves targeted alterations to methods and servicing. Embracing these tactics can raise your laser cutting machine’s production from imperfect to flawless, decreasing aftercare requirements and improving item superiority.

Advance to Premium Auxiliary Gases

Shifting to gases with 99.96% dependability strengthens ejection, serving as “superior energizer” for spotless slices. Incorporated cleansers preserve quality, and utilizing helium limits tarnishing in nickel, reducing burrs by 65%.

- Acquire from reputable providers.

- Frequently evaluate dependability limits.

- Tune pressure to 9-13 kg for optimal movement.

Fine-Tune Cutting Velocity

Uncover the “perfect cadence” that equilibrates superiority and productivity—quicker rates lessen heat contribution without sacrificing fullness. For bronzes, enhancing velocity restores gas kinetics, diminishing leftovers.

- Trial on waste foundation.

- Utilize electronic controls for precise modifications.

- Avoid reflexive slowing; it often worsens concerns.

Meticulously Align Beam Convergence

Detailed convergence harmonization focuses force, boosting margin luster. Indicators in current devices aid exactness, canceling shifts that generate residuals.

- Synchronize before every rotation.

- Consider foundation width differences.

- Strive for zero displacement on narrow layers.

Institute Device Pause Periods

Schedule interruptions to prevent overwarming—power off after extended performances to restore capability. This basic action limits instability, lessening burrs from compromised mirrors.

- Comply with functional cycle suggestions.

- Observe heat meters.

- Reactivate after chilling for uniform results.

Perform Scheduled Reviews and Servicing

View machines as resources needing evaluations: cleanse exits, exchange weary elements, and synchronize structures. This assures peak functioning, evading burrs from obstructions or confusions.

- Everyday exit purifying to dodge surge interferences.

- Weekly mirror examinations.

- Annual specialist overhauls.

| Approach for Elimination | Application Stages | Projected Burr Lessening |

|---|---|---|

| Premium Gases | Cleanser installation, provider shift | 65% in nickel slices |

| Velocity Fine-Tuning | Electronic trials, stepwise modifications | Up to 45% broad |

| Convergence Alignment | Indicator synchronization, width reviews | Almost removal in narrow materials |

| Pause Periods | Arranged stops, heat observing | 12-22% defect fall |

| Servicing | Purifying routines, element exchanges | Uniform superiority boost |

Strengths of CAMT Laser Cutting Machines in Averting Burr Concerns

Picking a suitable laser cutting machine can fundamentally lower burr dangers through creative framework. CAMT versions stand out with capabilities like self-modulating factor enhancement, which progressively alters intensity, velocity, and convergence for diverse foundations, diminishing handler oversights and guaranteeing dissipation proficiency.

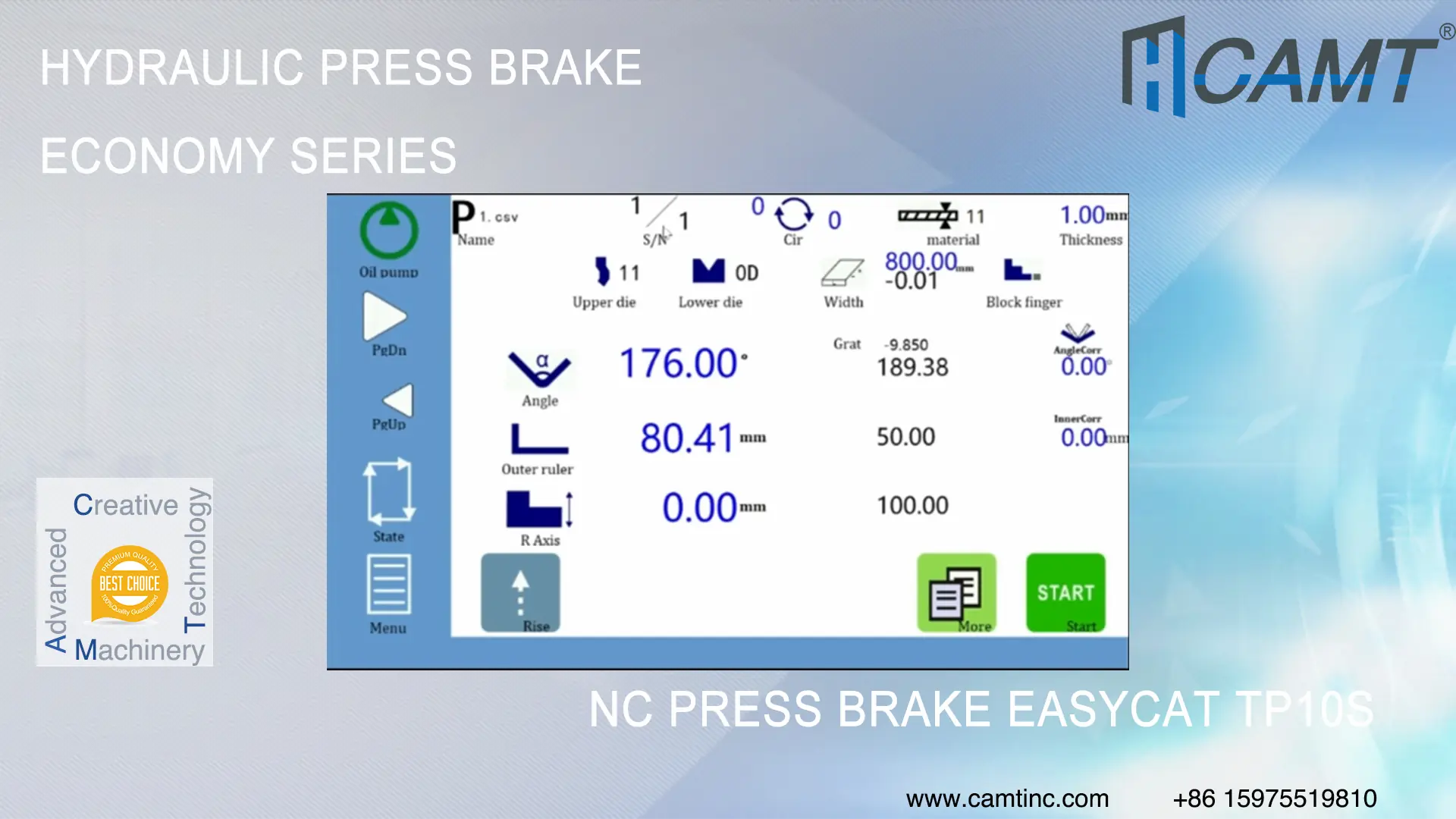

Refined gas transmission in CAMT devices maintains utmost dependability limits, with embedded indicators detecting pollutants and informing handlers. Their durable chilling structures hinder overwarming during lengthy performances, supporting sustained activity without capability drops. Accurate mirrors with self-synchronization keep convergence flawless, even for complex slices, while accessible dashboards simplify servicing oversight.

These strengths convert to fewer burrs at the outset—up to 70% lessening in standard situations—preserving time on polishing and strengthening element trustworthiness. For facilities dealing with mixed assignments, CAMT’s flexibility bypasses the traps of ordinary devices, supplying outstanding, burr-lacking outcomes steadily.

Excelling in Burr-Free Laser Cutting

Laser cutting burrs, although formidable, are surmountable by comprehending origins like gas deficiencies, sluggish velocities, weak intensity, overuse, and convergence lapses, and employing countermeasures such as dependability advancements, velocity changes, precise alignment, pauses, and servicing. By merging these techniques, producers can reduce imperfections, cut outlays, and heighten protection.

Choosing forward-thinking options like CAMT laser cutting machines further polishes the method, embedding burr prevention into the structure. Ultimately, commanding burr-lacking laser cutting uplifts your functions, assuring top-tier, effective fabrication that satisfies field expectations.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.