NC Press Brake EASYCAT TP10S System Manual

1. TP10S System Overview

The NC Press Brake EASYCAT TP10S is a reliable, cost-effective 10.1-inch full-color touchscreen CNC system developed specifically for Wuxi Isket WC67K-series torsion-bar synchronized hydraulic press brakes (40–400 Ton, 1.6–6 m length). It delivers ±0.05 mm repeatability through proven torsion-bar + dual-servo backgauge technology and is widely used for stainless steel, aluminum, mild steel, and galvanized sheet fabrication in electrical cabinets, automotive parts, kitchen equipment, and general sheet metal workshops.

Key Advantages

- 10.1″ TFT 256K color touchscreen (Chinese/English)

- Standard 4+1 axes (Y1-Y2-X-R + torsion sync), expandable to 6+1

- Fast servo X-axis (faster than most E21/DA41T systems)

- 220 programs × 24 steps, angle programming with automatic Y-depth calculation

- USB program transfer & optional angle measuring interface

2. Safety First – Mandatory Regulations

- Always enable light curtain/laser guard

- Never exceed rated tonnage by >20 %

- Check torsion-bar lubrication and oil temperature (<50 °C) daily

- Use proper die clamping tools – keep hands clear

- Emergency stop + CE-certified safety relay

3. Daily Startup & Homing Procedure

1.Power on: Main → Control → Pump (5 s delay)

2.Wait for self-check (≈30 s)

3.Press “REF” → Home Y → X → R → “REF OK” green light

4.Set units, language, and password (default 0000)

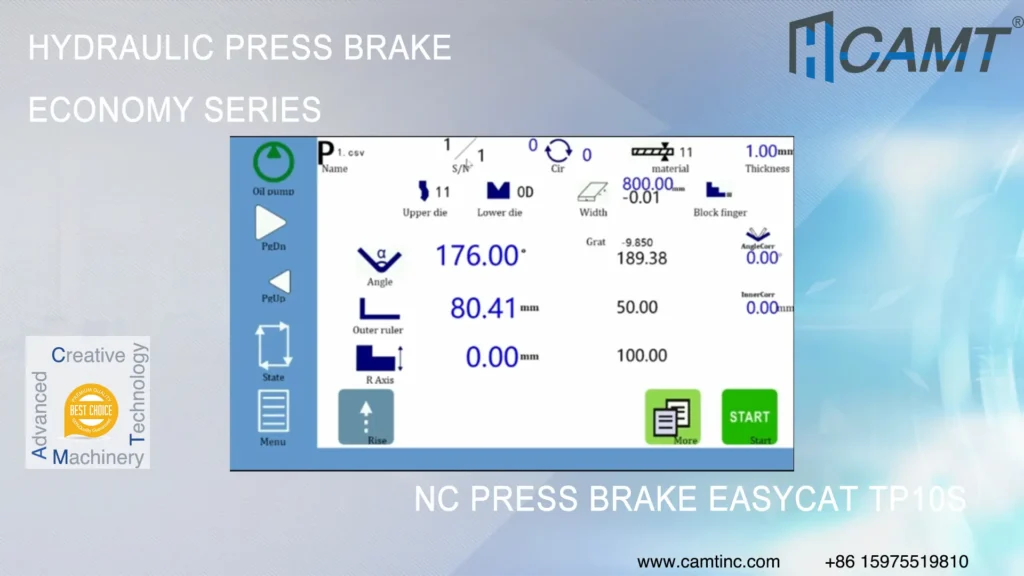

4. Interface Quick Guide

- Top: Mode & alarm status

- Left: Real-time axis positions

- Center: Program list / basic simulation

- Right: Quick icons (Program, Tools, Parameters, Diagnostics)

5. Manual Mode Operation

- Fast down → Auto slow → Bending → Return

- Y1-Y2 sync correction button (auto torque balance)

- X/R backgauge jog control

6. Tooling & Material Library

- Store up to 50 die sets

- Auto collision detection (minimum flange calculator)

- 20+ materials with automatic tonnage & spring-back calculation

7. Programming (Simple & Fast)

1.Touch “P” → New Program

2.Input bend length (L) + angle (α) → System auto-calculates Y depth & X position

3.Add retraction, dwell time

4.Simulate → Save → Run

8. Automatic Running & Advanced Features

- Single / Continuous / Step mode

- Batch counter with power-off memory

- R-axis auto retraction for large flanges

9. Parameters & Backup

Password 0000 (user) / 1234 (admin) → Adjust torsion pre-load, servo speed, compensation → One-key USB backup

10. Common Alarms & Quick Fix

- E001 Pump issue → Check motor

- E101 Y sync error → Lubricate torsion bar & re-home

- E203 X over travel → Adjust soft limits

- E305 Valve fault → Recalibrate zero point

11. Maintenance Schedule

- Weekly: Torsion-bar lubrication

- Monthly: Encoder cleaning

- Quarterly: Valve zero check

Why TP10S Remains the Top Choice Of NC Press Brake in 2025

The EASYCAT TP10S strikes the perfect balance between performance, simplicity, and cost for small to medium sheet metal shops. Compared to ESTUN E21 or basic Delem systems, it offers faster backgauge response, more stable torsion-bar synchronization, and easier angle programming — all at a significantly lower price point.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.