CAMT NEWS

Stay updated – subscribe now!

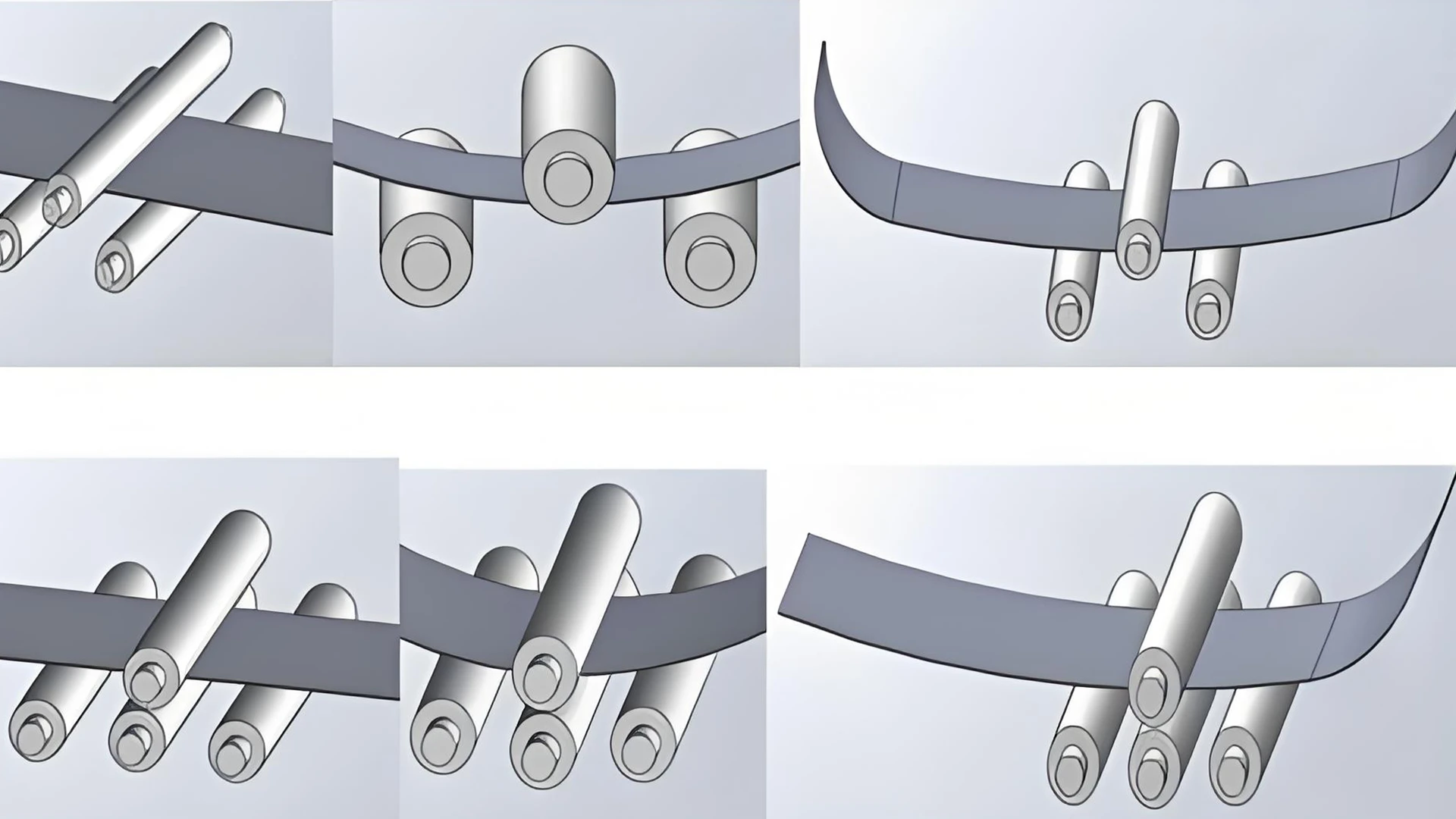

Working Principle and Characteristics of Plate Rolling Machine

Working Principle and Characteristics of Plate Rolling Machine Mastering Metal Curvature: The Plate Rolling Machine’s Innovative Design and Operational Edge In the dynamic field of metal fabrication, particularly within steel drum production, the plate rolling machine emerges as an indispensable tool that converts flat sheets into precise cylindrical forms. These

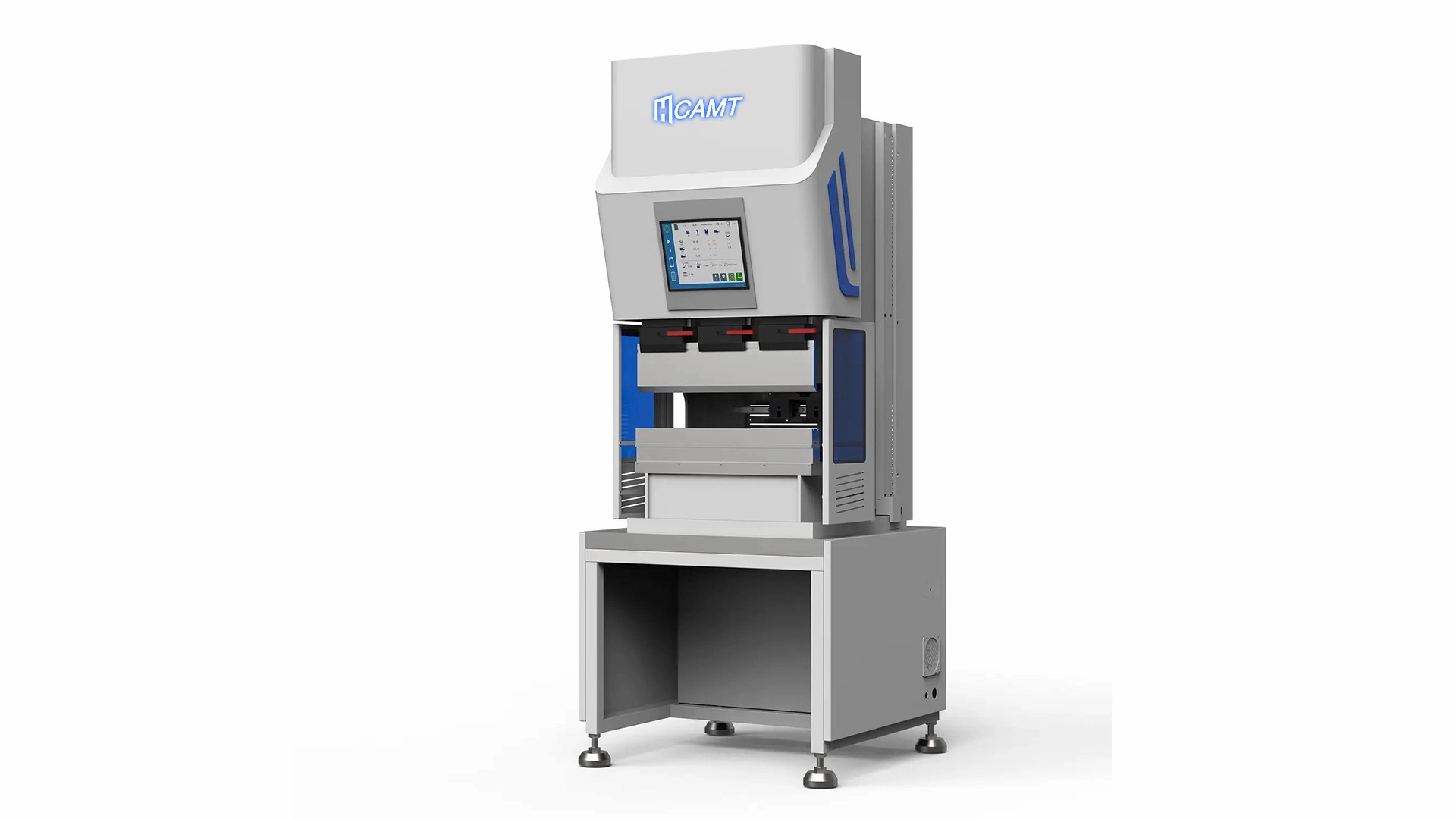

Technical Advantages of Electro-Hydraulic Servo CNC Press Brake

Technical Advantages of Electro-Hydraulic Servo CNC Press Brake The electro-hydraulic servo CNC press brake represents a significant advancement in sheet metal fabrication technology, integrating hydraulic power with servo-electric control to achieve enhanced performance metrics. This machine, often referred to interchangeably as a hybrid press brake due to variations in manufacturer

Laser Cutting Power and Frequency Adjustment Methods

Laser Cutting Power and Frequency Adjustment Methods Mastering laser cutting power and frequency is essential for achieving precise, efficient cuts in materials like metals, plastics, and woods. Laser cutting power determines the energy output of the beam, influencing speed and material interaction, while frequency controls the pulse rate, affecting smoothness

Applications and Differences Between Electric Press Brakes and CNC Press Brakes

Applications and Differences Between Electric Press Brakes and CNC Press Brakes In the ever-evolving landscape of manufacturing, where demands for efficiency, precision, and sustainability are pushing boundaries, press brakes stand as pivotal equipment in sheet metal fabrication. These machines, essential for bending metal into precise shapes, have seen significant technological

Why Panel Bending Centers Are the Future of Batch Automated Bending

Why Panel Bending Centers Are the Future of Batch Automated Bending The manufacturing landscape is undergoing a seismic shift, propelled by relentless demand for faster, more precise, and cost-effective production. Industries such as automotive, electronics, construction, and renewable energy are racing to deliver high volumes of complex sheet metal components

How to Choose the Right Press Brake System

How to Choose the Right Press Brake System In the world of metal fabrication, selecting the perfect press brake system can make or break your shop’s efficiency and output quality. Whether you’re running a high-volume production line or tackling custom prototypes, the control system is the brain behind every precise

Tandem Press Brake Working Principle and Applications

Tandem Press Brake Working Principle and Applications In the fast-evolving landscape of modern manufacturing, traditional methods often fall short in meeting demands for speed, precision, and scalability. As industries push for higher efficiency, many companies are turning to advanced equipment like the tandem press brake to streamline their operations. This

Differences Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines

Differences Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines Navigating the Choice Between Fiber Laser Cutting Machines and CO2 Laser Cutting Machines When investing in a laser cutting machine, businesses often face a challenging decision. Without clear standards or comprehensive data, many default to price as the sole

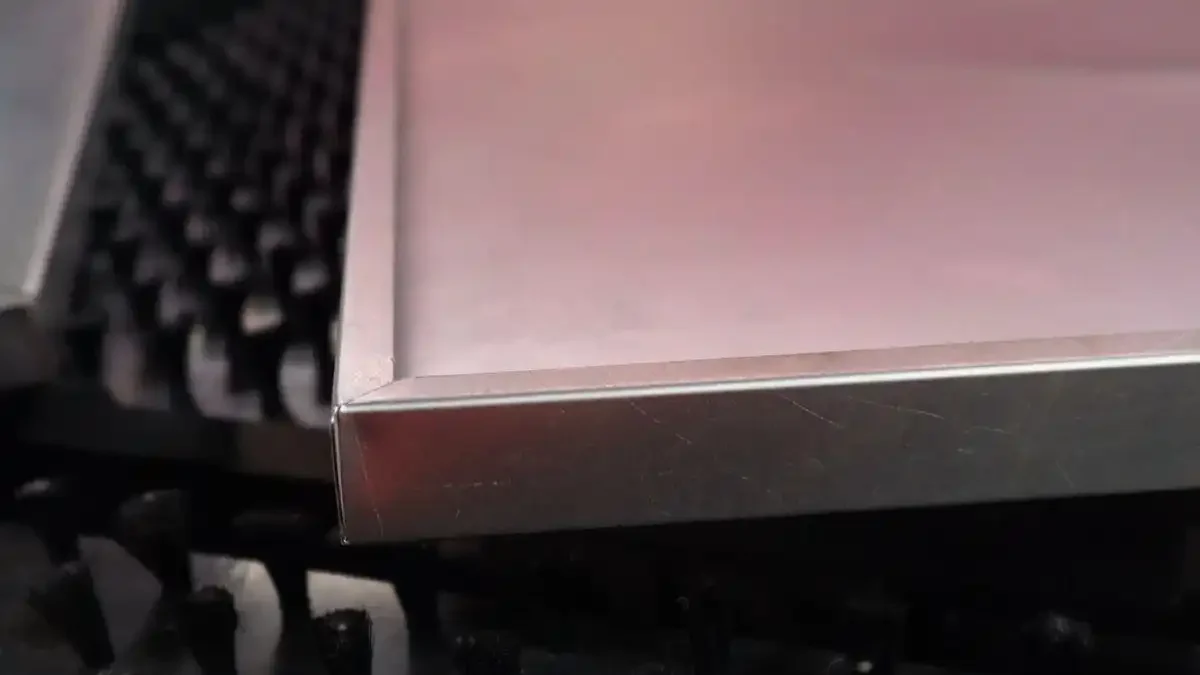

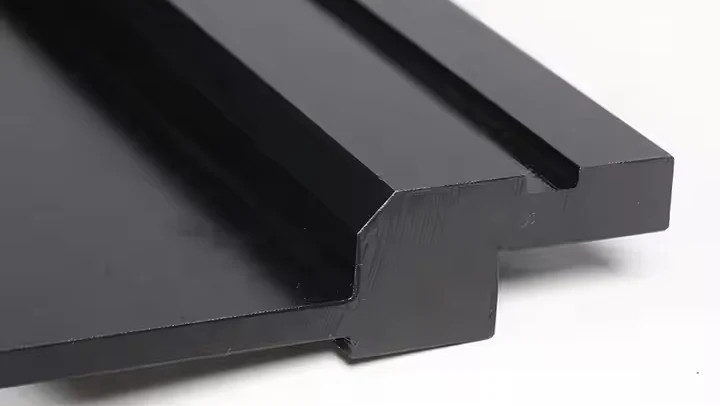

How to Choose the Right Press Brake Tooling

How to Choose the Right Press Brake Tooling Press brake tooling often referred to as bending machine dies, comes in various depths and configurations, tailored to different sheet materials. This variety drives a need for precise classification and selection. But what exactly determines which tooling suits a specific material? The