CAMT-INNOVATION MEETS PRECISION

Popular Sychronous Press Brake Smart 3-4 Axis

CAMT

Popular Sychronous Press Brake Smart 3-4 Axis

CNC Press Brake Machine For Precise Metal Fabrication

Competitive Pricing:Economic Metalworking Solution Handle Most Scenarios

CAMT®️Popular Sychronous Press Brake Smart 3-4 Axis exemplifies superior craftsmanship and dedicated service, offering an extensive lineup of models with bending lengths ranging from 1.6 to 6 meters and bending forces from 40 to 600 tons, meticulously tailored to accommodate diverse application requirements and customized specifications. Equipped with our proprietary bending system, it features a 21.6-inch high-resolution display, sophisticated bending calculation capabilities, and automated arc bending functionality, ensuring precision and operational finesse. Clients may select from advanced control systems, including DELEM 53T, 58T, Cybelec CybTouch 12, or ESA640, to align with their operational preferences. The integrated servo motor, engineered for minimal electromagnetic interference, delivers operational speeds 20-30% higher than industry benchmarks, optimizing productivity while maintaining competitive pricing and exceptional cost-performance, positioning it as a leading solution for Y1/Y2 technology.

Constructed with exacting standards for comprehensive machining, achieving exemplary horizontal and vertical accuracy, our press brakes are designed for enduring reliability, minimal maintenance, and consistent performance, providing clients with robust, high-quality bending solutions.

CAMT Popular CNC Bending Solution

Incorporates the Following Attributes and Capabilities

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Preferential Quality with Less Error Rate

Faster Working Efficiency

Eco-friendly;40% Energy Saved

More Refined Y1/Y2 Control Effect

Popular Configuration

- 21.6-inch color high-definition touch screen with friendly human-machine interface

- CHTR Rear BGA 600MM with 300MM/S

- 4 V Double CNC die series &835mm punches

- High Precision & Multi Point Mechanical Crowning

- Imported Italy GIVI Maganetic Misure

- FULL Close-loop High Performance Hydrauic System

- All-In-One Effective Servo Motor

- Graphite Self-lubricating Copper Plate

- Safety France Schneider Electric System Components

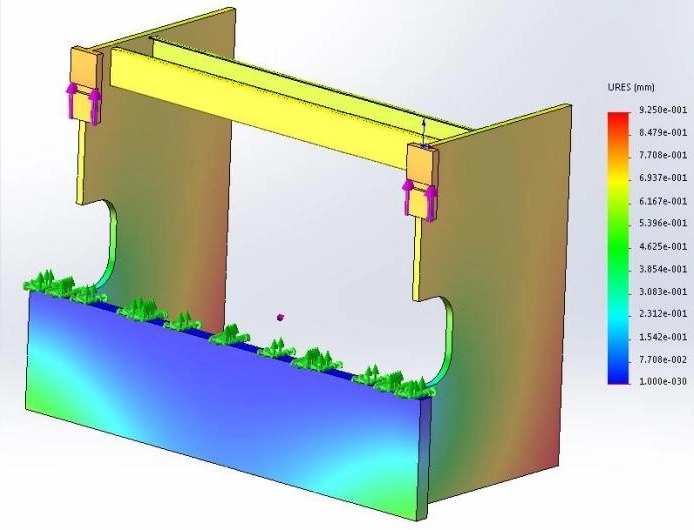

FEA & Stress Analysis

Stress Analysis & Finite Element Analysis

Overseas After-Service Support Bending System

Taiwan TECHMATION SCS700 Automation

- Utilizes high-precision industrial-grade color touch screen

- Comes with SECOT dual-language version (supports logo or image customization)

- Supports one-button color switching, approximately 1024*768 resolution

- Utilizes platform industrial-grade display

- Newly developed industrial-grade MEC4 embedded version, customizable

- Supports multiple expansion options: color, machine motion control, USB port (image loading), CAN expansion, etc. Optional features.

Stragetic Cooperation with DELEM/CYBELEC to Satisfied Usage Habit

DELEM DA53T Touch CNC System

- 10.1" high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

Intergral Advanced CNC Control System

More Than 10 Years R&D CNC Control

- 21..6-inch color high-definition touch screen with friendly human-machine interface

- "One-page" programming navigation, one page can display all data, and it isfaster to modify the curve information

- The system supports 4-axis control, meeting the highest control conditions of 4+1+2 axis bending machine

- The Linux operating platform is stable and reliable, with fast startup speeddand can be directly powered off and shut down

- The bending data is automatically calculated, the bending speed of each step is programmable, the slow down and mid-stop can be controlled, and thehome page has convenient functions such as fast mold alignment, so novicescan quickly get started

- Rich interfaces, can be easily and conveniently connected to the automateddproduction line as a bending unit

CAMT CHTR Rear BackGauge

Standard X&R Axis with High Performace Linear Guide

- Enables precise backGauge positioning with an accuracy of typically ±0.01mm, suitable for high-precision bending needs.

- BackGauge speed up to 300 mm/s with a precise positioning accuracy.

- Quick response times, allowing rapid adjustment of the back gauge position to improve production efficiency.

- Consistent performance even under prolonged high-load conditions, minimizing errors.

- multi-axis (X, R) linkage, flexibly accommodating the processing requirements of complex workpieces and enhancing machining versatility.

- Automated programming and operation, reducing manual intervention and suiting mass production.

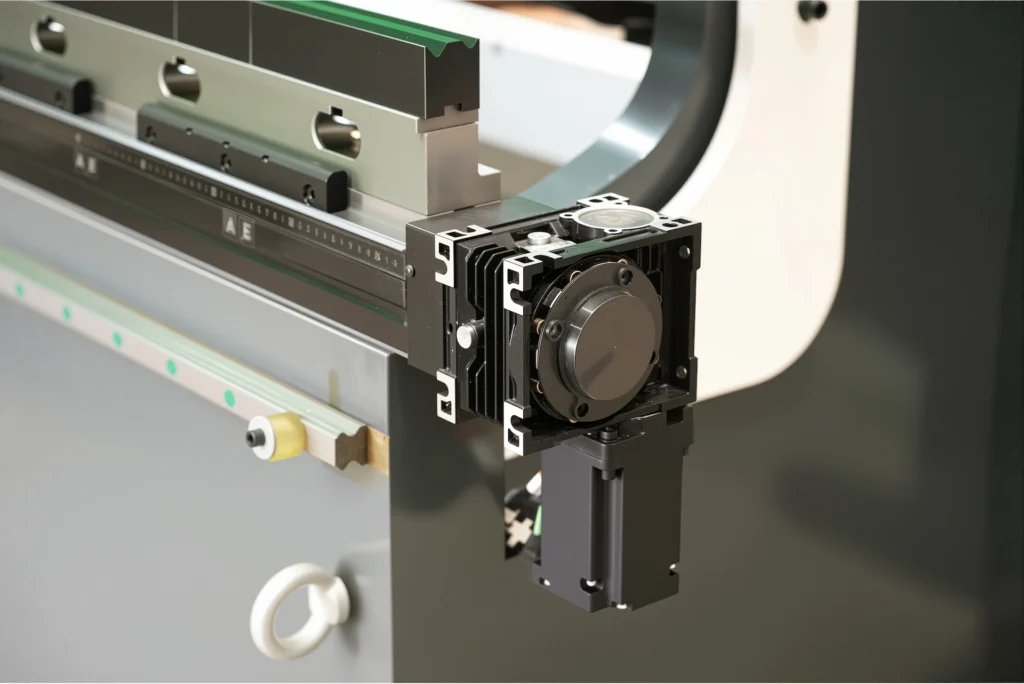

GIVI MISURE

Italy Importaed Maganetic Ruler - Precise Postioning and On-time Reaction

Optional Safety Arrangement - Light Curtain

- Effectively preventing injuries during bending processes.

- Up to EN 12622 meet legal requirements and avoid liability issues.

- Enabling safe and efficient workflows by detecting intrusions in real time

- High Sensitivity and Accuracy

- Flexibility for Diverse Applications

- High safety standards, Ahieve SIL 3 (Safety Integrity Level 3)

- Supporting efficient production

Mechanic Compensation

Precise Effectiveness & Muti-Point Crowning

China Strict Inspection Oil Cylinder

- High Durability: High-quality steel and undergoes meticulous processing, ensuring exceptional durability, strong compressive strength, and substantial weight to withstand heavy-duty operations.

- Simplified Operation: Effectively reducing on-site setup time and extending the lifespan of components.

- Comprehensive Capabilities: Robust quality control and inspection system during production, ensuring that finished workpieces meet standards while maintaining complete functionality and smooth operation.

- Structural Compactness: Compact yet sturdy design, with a tight structure that ensures efficient storage and operation, enhancing support effectiveness.

- Ease of Maintenance: Convenience, offering easy maintenance, user-friendly operation, and a longer service life, minimizing on-site labor and manpower requirements.

Bending Tool & Fast Clamping:

Advantage:

- Superior Tooling Durability: Crafted from 42CrMo steel, the tooling undergoes high-temperature forging and quenching to achieve a hardness of 47-49HRC, delivering exceptional bending performance and resilience across diverse working conditions.

- Enhanced Precision: The 835mm segmented CNC concentric mold design ensures precise centering, improving accuracy for complex bending tasks.

- Efficient Tool Changes: Features a quick-clamp system for rapid tool replacement, supporting both front (vertical) and rear (horizontal) configurations, increasing operational efficiency and reducing labor requirements.

- Versatile Compatibility: Designed to seamlessly accommodate European-style punches without modification, offering flexibility for various applications.

CAMT Itergral Hydraulic System

Advanced Hybrid Servo ECO Technology

Advantage:

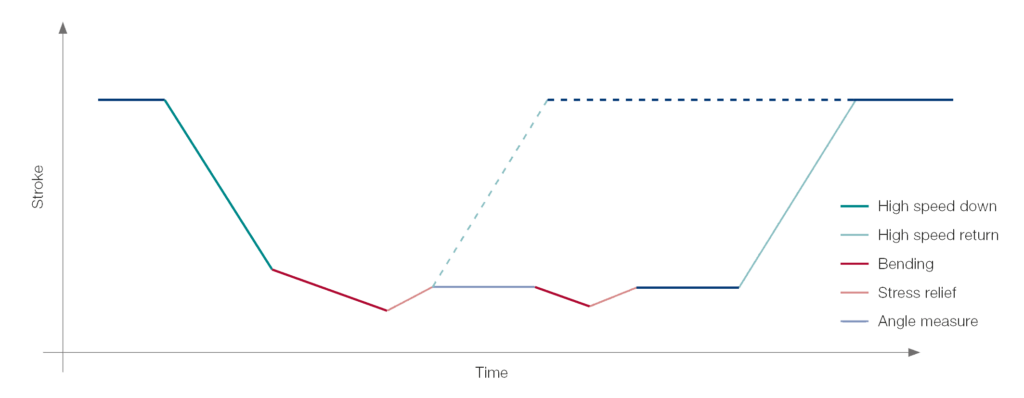

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.