Practical Guidance For Press Brake Operation

Introduction to Press Brake Operation

Press brake operation is one of the most critical processes in sheet metal fabrication. Regardless of machine brand or control system, bending accuracy and repeatability depend largely on how the machine is operated rather than on the machine itself. Even advanced CNC press brakes require correct setup, proper tooling installation, and reasonable parameter adjustment to perform reliably in daily production.

In practical manufacturing, many bending problems such as angle deviation, unstable consistency, or excessive tool wear are not caused by mechanical failure. They usually result from incorrect operation, insufficient understanding of tooling behavior, or neglect of material variation. This article explains press brake operation from a practical perspective, combining operating principles with real production experience to help users improve bending quality while maintaining machine safety and long-term stability.

Tooling Installation in Press Brake Operation

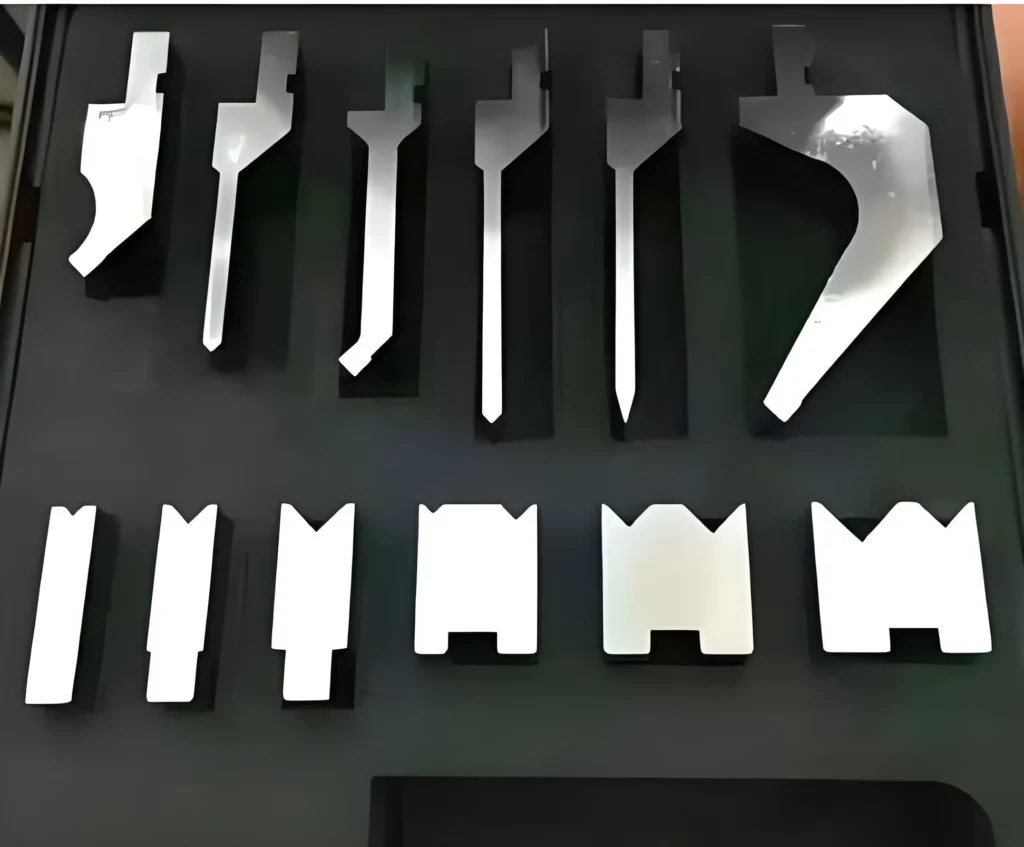

Correct tooling installation is the foundation of reliable press brake operation. Upper punches and lower dies must be selected according to sheet thickness, bending length, required angle, and part geometry. Although standard tooling drawings are often supplied with the machine, they serve only as general references. Actual tooling choice should always be based on the specific application and machine capacity.

Upper Punch Installation and Alignment

When installing or replacing the upper punch, the clamping screws on the punch holder should be loosened just enough to allow controlled movement. Over-loosening increases safety risks and may cause the punch to fall unexpectedly. The punch should be removed and inserted from the end of the machine, ensuring that the safety shoulder is correctly seated in the holder groove.

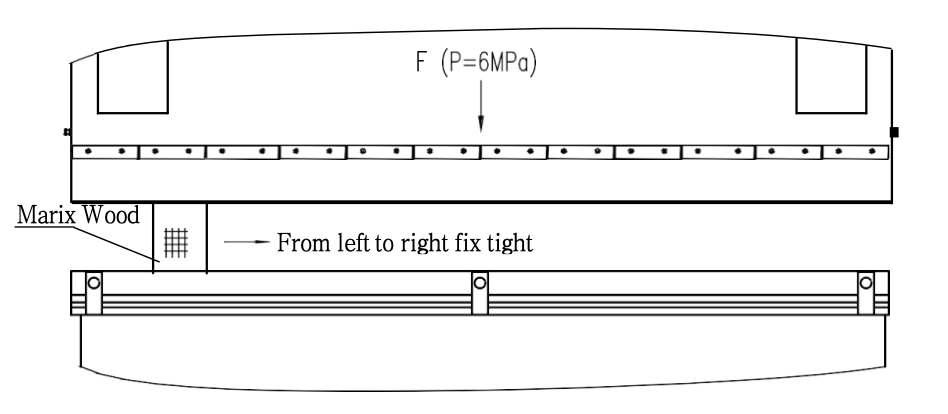

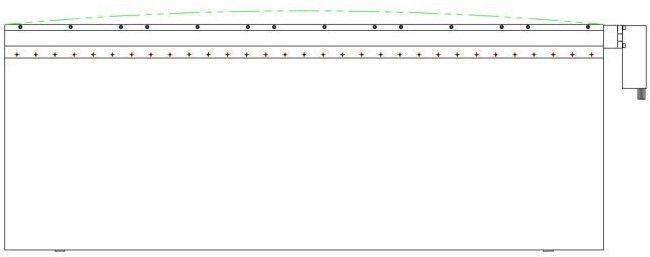

At this stage, the clamping screws should only be lightly tightened. To ensure proper contact between the punch and the ram, the hydraulic system pressure should be set to approximately 6 MPa. A wooden block placed between the upper and lower tools allows the punch to be pressed gradually into position from one side to the other. Once uniform contact is confirmed along the full working length, the clamping screws can be fully tightened. This procedure prevents uneven loading and improves bending consistency.

Lower Die Selection and Positioning

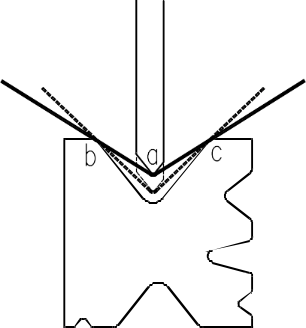

Lower die selection plays an equally important role in press brake operation. As a general rule, the V-opening width should be eight to ten times the sheet thickness. Smaller V-openings provide better angle control but require significantly higher bending force, while larger openings reduce tonnage demand and tool stress.

After placing the lower die in position, the fixing bolts should be lightly tightened. The ram is then jogged down to bottom dead center, leaving a small clearance between the upper and lower tools. Uniform clearance along the entire length indicates correct alignment. If uneven gaps are observed, the die can be gently adjusted using a wooden or rubber hammer before final tightening. Proper die positioning is essential for maintaining consistent angles, especially when bending long parts.

Ram Stroke Control and Its Effect on Press Brake Operation

Ram stroke control directly affects both efficiency and accuracy in press brake operation. On CNC press brakes, stroke parameters are adjusted through the numerical control system, allowing precise and repeatable movement.

Upper Dead Point Adjustment

The upper dead point determines how high the ram opens after each bending cycle. Setting this position higher than necessary increases cycle time without improving safety. In practice, the upper dead point should be adjusted to provide sufficient clearance for part handling while keeping the stroke as short as possible to improve productivity.

Speed Change Point Adjustment

The speed change point defines where the ram transitions from fast approach to working speed. If this transition occurs too late, impact forces may damage tooling or affect surface quality. If it occurs too early, production efficiency is reduced. Proper adjustment allows fast positioning while maintaining controlled contact during bending.

Bottom Dead Point and Angle Control

In air bending press brake operation, the bending angle is controlled by the penetration depth of the upper punch into the V-opening of the lower die. Deeper penetration results in smaller angles. CNC systems allow operators to fine-tune this depth with high precision. When the achieved angle does not meet requirements, minor parameter adjustments can be made directly in the control system until the desired result is reached.

Back Gauge Adjustment in Press Brake Operation

The back gauge is responsible for accurate rear positioning of sheet metal during bending. In CNC press brake operation, back gauge movement is controlled through the CNC system, providing high positioning accuracy and excellent repeatability.

Modern back gauge systems often include a retraction function, allowing continuous bending without manual repositioning between bends. This feature significantly improves efficiency in batch production. The height of the back gauge fingers should be adjusted according to the workpiece, typically set slightly above the upper surface of the lower die to provide stable support without interfering with bending.

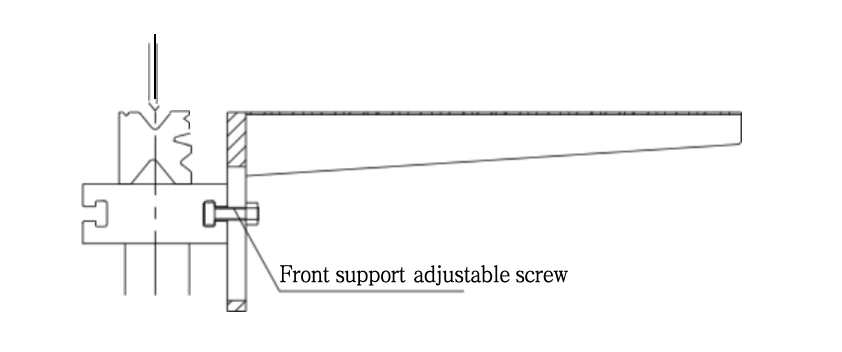

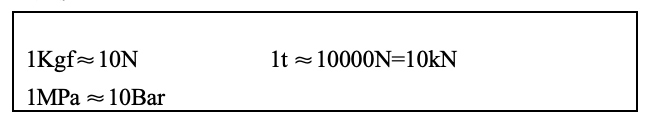

Front Support Adjustment for Large Workpieces

Front supports play an important role in press brake operation when handling large or thin sheets. Without proper support, sheets may sag or shift during positioning, leading to inaccurate bends and increased operator effort.

The front support height should be adjusted so that the support surface is level with the top surface of the lower die. This alignment allows smooth material movement and stable positioning before bending, reducing physical strain on the operator and improving consistency.

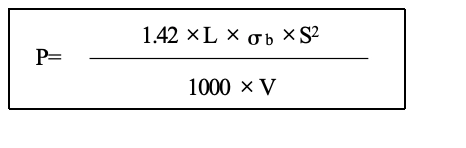

Pressure Adjustment and Force Calculation

Hydraulic pressure adjustment is a core aspect of press brake operation. The required bending force depends on several factors, including material thickness, bending length, die opening width, and material tensile strength. Applying excessive pressure increases tool wear and machine stress, while insufficient pressure leads to incomplete bending and angle deviation.

In practical production, bending force is calculated using standard formulas and then adjusted with a safety margin of approximately ten percent. CNC press brakes simplify this process by automatically calculating and setting the required pressure based on input parameters. Proper pressure control protects both the machine and tooling while ensuring stable bending results.

Accuracy Factors in Press Brake Operation

Bending accuracy is influenced by multiple interacting factors. Sheet thickness variation is one of the most common causes of angle inconsistency. Even small thickness differences can lead to noticeable angle changes, particularly when narrow V-openings are used. For this reason, mixing materials from different batches should be avoided whenever possible.

Machine deflection under load also affects bending accuracy. During full-length bending, the table and ram experience elastic deformation. Crowning systems compensate for this deflection, ensuring uniform angles along the entire workpiece. Correct crowning adjustment is especially important when bending long parts or working close to the machine’s rated capacity.

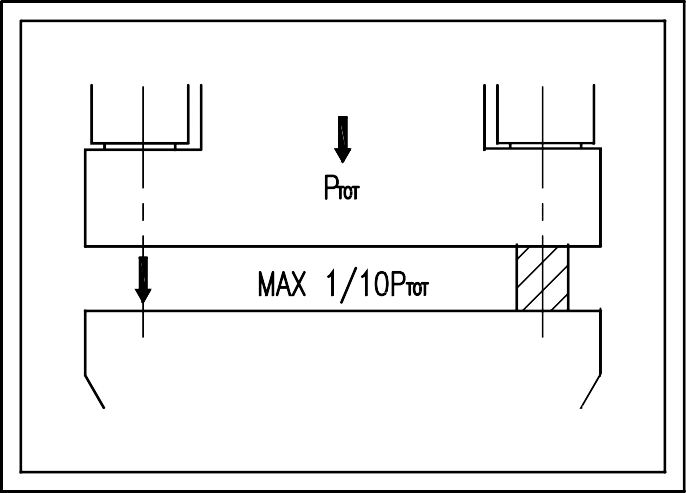

Off-center loading represents a serious risk in press brake operation. Applying bending force on only one side of the machine causes uneven column deformation and may result in permanent structural damage. Standard press brakes are not designed for off-center bending. If such operation is unavoidable, the applied load must remain within a very small percentage of the machine’s rated capacity.

Operational Experience and Common Issues

Inconsistent angles along the length of a workpiece often indicate insufficient crowning compensation or improper tool alignment. Regular inspection of tooling installation and compensation settings helps prevent these issues. Angle variation between production batches is commonly caused by differences in material tensile strength or gradual tool wear. Measuring the first few parts of each batch and applying small corrections is standard practice in professional press brake operation.

Surface marks on stainless steel or aluminum sheets are another frequent concern. These issues can often be reduced through appropriate tooling selection, such as using punches with larger radii or applying protective measures during bending. Such adjustments improve surface quality without compromising accuracy.

Maintenance and Safety in Long-Term Press Brake Operation

Stable press brake operation over time depends on proper maintenance and disciplined safety practices. Daily inspection of hydraulic oil level, tooling clamping condition, and back gauge movement helps identify potential issues before they affect production. Periodic maintenance, including oil replacement and inspection of seals and hoses, ensures long-term machine reliability.

Safety awareness is essential at every stage of operation. Setup and adjustment procedures should always be performed in jog mode, and safety devices must never be bypassed. Operators should maintain a clean working area and keep hands away from the tooling zone at all times. Most serious accidents occur when routine procedures are ignored or rushed.

Conclusion

Press brake operation is not simply about running a machine. It requires a clear understanding of tooling behavior, material properties, machine limitations, and safe working methods. While CNC technology has greatly improved control accuracy and ease of use, the fundamentals of correct operation remain unchanged.

By applying proper tooling installation methods, accurate pressure adjustment, reasonable CNC parameter settings, and consistent maintenance routines, manufacturers can achieve stable bending accuracy, reduce scrap rates, and extend machine service life. A well-controlled press brake operation forms a reliable foundation for consistent product quality and long-term production efficiency.

Frequently Asked Questions About Press Brake Operation

How does material variation affect press brake operation?

Material variation is one of the most underestimated factors in press brake operation. Even when sheet thickness appears consistent, differences in tensile strength, rolling direction, or surface treatment can cause noticeable changes in bending angle. In daily production, this is why the same CNC program may produce slightly different results when materials come from different suppliers or batches. Experienced operators usually verify the first few bends of each batch and make small angle or depth corrections to compensate for material behavior rather than relying entirely on preset values.

Why does the bending angle change even when the CNC program remains unchanged?

When press brake operation produces different angles under the same program, the cause is rarely the control system itself. More commonly, changes in material properties, gradual tool wear, temperature differences, or minor shifts in tooling alignment are responsible. Over time, even small changes accumulate and affect results. Regular inspection of tooling condition and periodic recalibration of bending parameters help maintain consistent output.

How important is lower die selection in press brake operation?

Lower die selection has a direct impact on bending force, angle stability, and tool life. Using a V-opening that is too small increases tonnage demand and accelerates tool wear, while an overly large opening may reduce angle precision and increase springback variation. In practical press brake operation, selecting a V-opening between eight and ten times the sheet thickness offers a balanced solution for most applications, combining acceptable accuracy with reasonable machine load.

Can press brake operation be safely performed with off-center loading?

Standard press brake operation is not designed for off-center loading. When bending force is applied unevenly to one side of the machine, structural components such as columns and frames experience unbalanced stress, which can lead to permanent deformation. In special cases where off-center bending cannot be avoided, the applied load must be kept to a very small percentage of the machine’s rated capacity, and such operations should be minimized to protect the machine over the long term.

What role does crowning play in press brake operation?

Crowning compensation is essential for maintaining uniform bending angles along the full length of a workpiece. During press brake operation, the table and ram naturally deflect under load, especially during long or heavy bends. Without proper crowning adjustment, angles at the center and ends of the workpiece may differ. Correctly adjusted crowning offsets this deflection and ensures consistent results across the entire bending length.

How can tool marks be reduced during press brake operation?

Tool marks are a common concern when bending stainless steel, aluminum, or coated sheets. In many cases, these marks are not caused by incorrect pressure but by tooling geometry. Using punches with larger radii, applying protective films, or selecting specialized anti-marking tooling can significantly improve surface quality. Adjusting bending methods while maintaining correct press brake operation parameters allows manufacturers to meet both dimensional and cosmetic requirements.

What daily practices help maintain stable press brake operation?

Stable press brake operation relies heavily on routine discipline rather than complex procedures. Simple daily checks, such as verifying hydraulic oil level, ensuring tooling clamping is secure, and confirming smooth back gauge movement, help prevent unexpected issues. Keeping the working area clean and following consistent setup procedures also reduces variability and improves long-term reliability.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.