Order visualization, production process traceability

Improved yield rate, more stable quality control

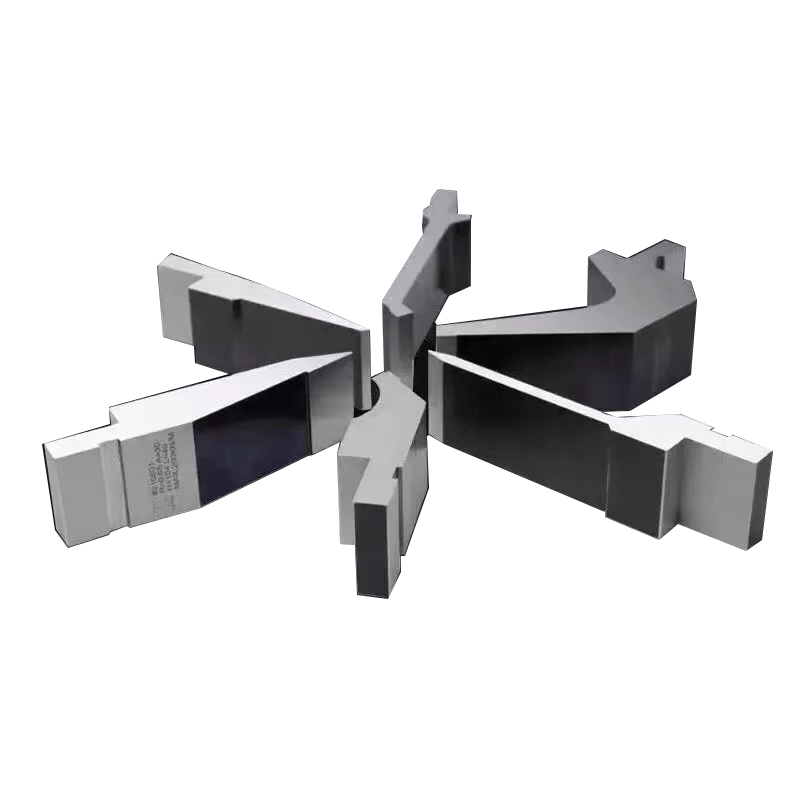

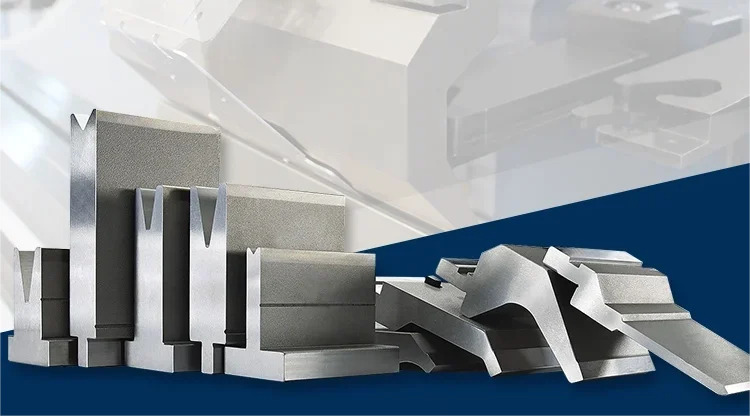

CAMT press brake tooling, is used in bending machines to shape sheet metal into specific forms. Comprising parts like punches, die blocks, and guide pins, different molds suit varied bending needs. By applying pressure, the tooling bends, stretches, or compresses the material, transforming blanks into precise components with consistent shapes and sizes.

High-quality tooling ensures precise bends, reducing errors and material waste for cost efficiency. Durable designs extend lifespan, lowering maintenance costs. Enhanced repeatability ensures consistent production, while versatile molds handle complex shapes and diverse materials, meeting varied manufacturing demands effectively.

Add Your Tooltip Text Here

Copyright 2025 | All Rights Reserved | CAMTINC