Why Panel Bending Centers Are the Future of Batch Automated Bending

The manufacturing landscape is undergoing a seismic shift, propelled by relentless demand for faster, more precise, and cost-effective production. Industries such as automotive, electronics, construction, and renewable energy are racing to deliver high volumes of complex sheet metal components while navigating tight deadlines and shrinking margins. Enter the panel bending center—a transformative technology that’s redefining batch automated bending. These advanced machines deliver unmatched efficiency, pinpoint precision, labor-saving automation, and remarkable versatility, positioning them as the cornerstone of modern sheet metal fabrication. In this comprehensive guide, we’ll explore why panel bending centers are revolutionizing high-volume production and why CAMT’s panel bending center stands out as the ultimate solution for manufacturers aiming to dominate their markets.

Maximizing Throughput: The Efficiency Edge of Panel Bending Centers

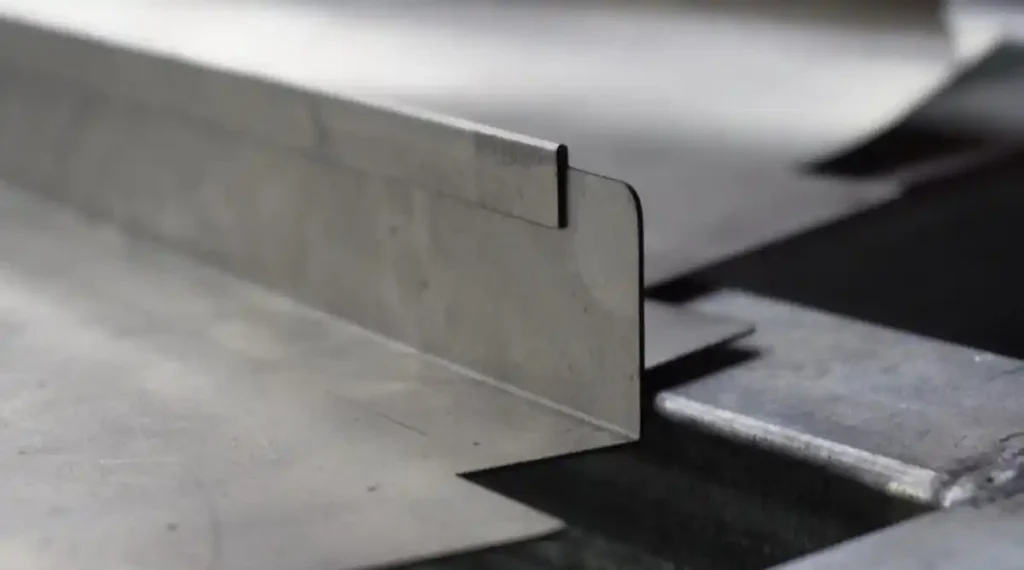

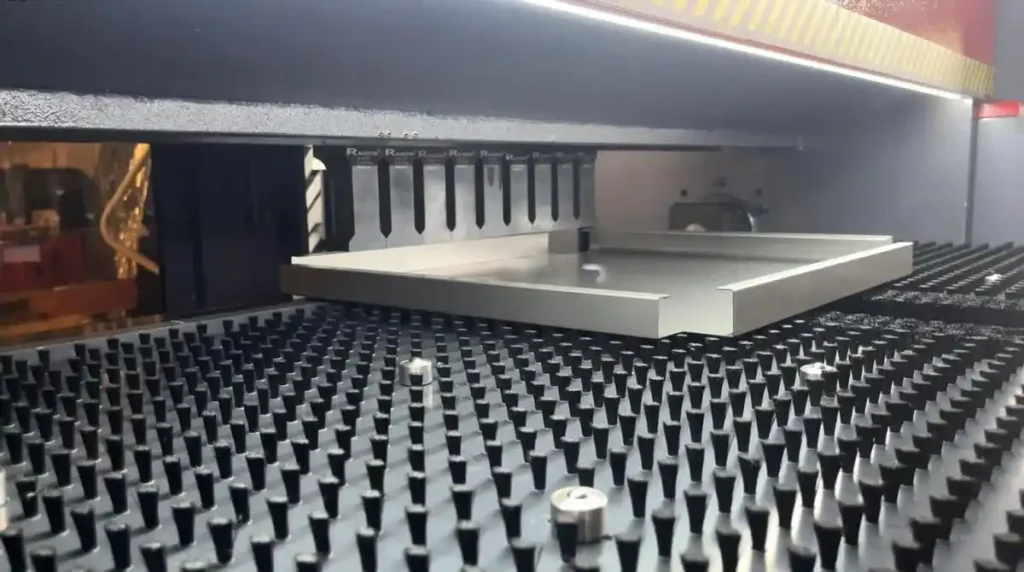

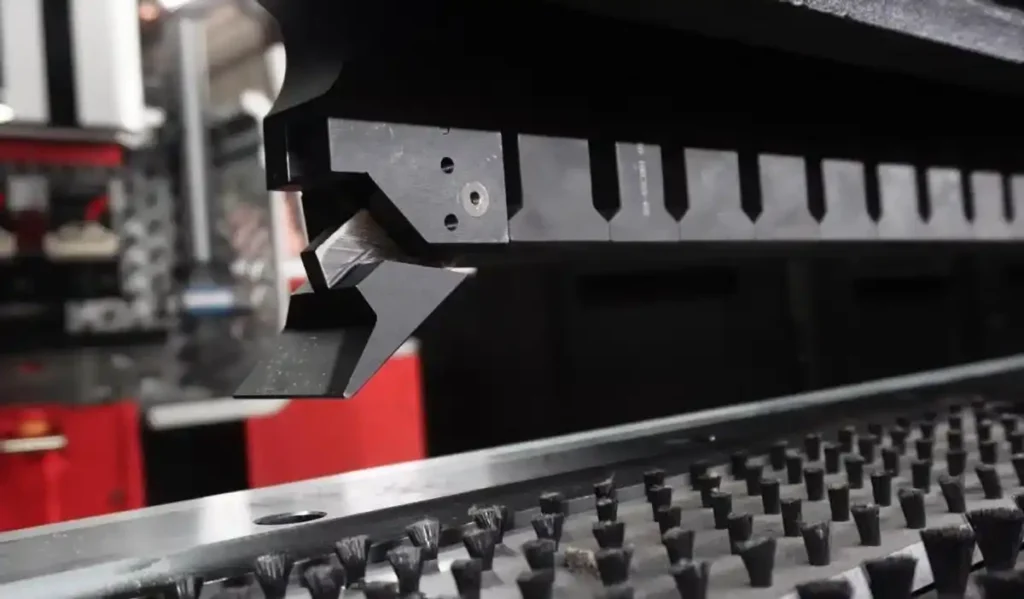

In the high-stakes world of batch manufacturing, efficiency is king. Every second saved in the production cycle translates to higher output, lower costs, and a competitive edge. Panel bending centers outshine traditional press brakes by delivering processing speeds 2-3 times faster, turning multi-hour jobs into streamlined, high-throughput operations. Their innovative design is the key: sheet metal remains flat and stationary, secured by a dynamic blankholder, while articulated bending arms equipped with universal tools execute precise folds from above and below. This eliminates the repetitive repositioning and manual handling that bog down conventional systems, slashing cycle times by up to 70% in some cases.

Consider a typical scenario in automotive component production: a panel bending center can process complex brackets or panels at a rate of 20-30 bends per minute, compared to 10-15 on a standard press brake. This speed advantage stems from optimized kinematics—only the feeder mechanism moves, while the workpiece stays fixed, reducing idle time. Nesting efficiency also jumps by up to 60%, allowing manufacturers to pack more parts per sheet, which cuts material waste and boosts profitability. For a shop producing thousands of electrical enclosures weekly, this translates to a 50% increase in output without expanding floor space or labor.

Automation amplifies these gains. Robotic grippers handle sheet loading, rotation, and unloading with precision, enabling continuous production even during off-hours. For example, in a Midwest facility producing HVAC components, integrating a panel bending center with automated material handling slashed downtime by 40%, enabling 24/7 runs. Automatic tool changers further streamline operations, switching dies in under 30 seconds to accommodate diverse part geometries without halting production. This is a game-changer for manufacturers balancing large-scale orders with small, custom batches, as it minimizes setup delays and ensures rapid response to customer demands.

But efficiency isn’t just about speed—it’s about scalability and adaptability. Panel bending centers excel in high-mix, high-volume environments, seamlessly transitioning between jobs. For instance, a shop might produce 1,000 server rack panels in the morning and switch to 200 custom appliance housings by afternoon, all without retooling. Industry data highlights that these machines can increase throughput by up to 60% in dynamic settings, making them ideal for just-in-time delivery models prevalent in today’s markets.

To maximize efficiency with a panel bending center, manufacturers should consider:

- Batch Optimization: Target runs of 500+ parts for maximum ROI; semi-automated setups work for smaller lots.

- Material Compatibility: Supports a wide range of alloys—aluminum, stainless steel, galvanized steel—up to 3 meters in length and 0.5-4mm thick.

- Software Integration: Pair with CAD/CAM systems for offline programming, reducing setup times by 50% and minimizing errors.

- Shop Floor Planning: Compact footprints (as small as 5m x 3m) fit most facilities, but ensure clearance for robotic arms and material staging.

- Operator Training: Leverage intuitive interfaces to upskill staff quickly, ensuring smooth adoption.

Real-world impact? A European manufacturer of renewable energy components reported doubling their output after adopting a panel bending center, cutting delivery times from weeks to days. This efficiency edge transforms production bottlenecks into competitive advantages, making panel bending centers indispensable for scaling batch operations.

Precision Engineering: Delivering Flawless Quality with Panel Bending Centers

n batch production, quality isn’t just a goal—it’s a mandate. A single defective part can trigger costly rework, disrupt assembly lines, or damage customer trust. Panel bending centers excel by delivering micron-level precision, ensuring every part meets exacting specifications. Advanced servo-driven systems and wedge-style transmissions eliminate mechanical play, maintaining angle tolerances as tight as ±0.5 degrees across thousands of cycles. Proprietary algorithms analyze real-time variables—material springback, thermal expansion, sheet thickness—to optimize bending force, ensuring first-part accuracy without iterative adjustments.

Non-contact laser angle measurement systems elevate quality further. By projecting a laser beam onto the flange and using high-resolution cameras to verify geometry, these systems detect deviations as small as 0.2 degrees and auto-correct on the fly. This ensures consistency across batches, whether producing 500 brackets or 5,000 panels. Universal tooling adds another layer of reliability, handling diverse geometries—from sharp hems to wide radii—with a single die set, reducing variability that plagues traditional setups. Industry studies show panel bending centers cut angular errors by 40% compared to conventional presses, directly improving downstream fit-up and reducing scrap rates.

Take the electronics industry as an example: producing server chassis demands flawless angles to ensure components align perfectly. A panel bending center’s ability to hold tolerances to 0.1mm across high-volume runs eliminates costly rejections. In a case study from a telecommunications supplier, adopting this technology reduced quality-related returns by 30%, saving thousands in rework costs. The integration of real-time feedback loops also provides traceability, generating audit trails for every part—a critical feature for industries like aerospace or medical devices where compliance is non-negotiable.

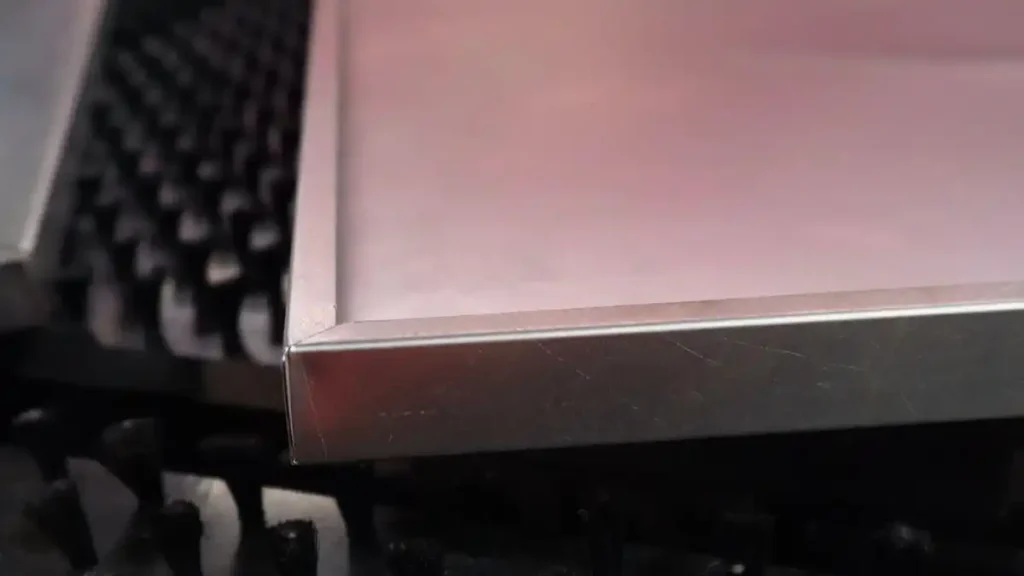

Precision extends to material handling. Unlike press brakes, which require operators to flip heavy sheets, panel bending centers keep workpieces stationary, minimizing scratches or surface damage. This is particularly valuable for pre-finished materials like coated stainless steel used in consumer appliances, where aesthetics are as critical as function. Additionally, adaptive bending algorithms account for material inconsistencies, such as slight variations in thickness across a coil, ensuring uniformity across batches.

To achieve and maintain top-tier quality:

- Sensor Calibration: Schedule bi-weekly checks on laser systems to ensure sub-degree accuracy。

- Material Profiling: Create a digital library of bend allowances for each alloy to streamline setups.

- Pilot Testing: Run 10-part samples for new programs to verify repeatability before full production.

- Quality Integration: Connect to ERP systems for real-time defect tracking, enabling rapid process tweaks.

- Preventive Maintenance: Regularly inspect servo motors and transmissions to sustain precision over time.

Challenges exist—thicker materials (>3mm) may require specialized tooling—but modern panel bending centers handle these with hybrid modes, blending automation with targeted manual oversight. For manufacturers aiming to deliver flawless batches, these machines turn quality into a competitive strength, ensuring products meet the highest standards with minimal waste.

Streamlined Automation: Cutting Costs with Panel Bending Centers

Labor costs are a growing pain point for manufacturers, with skilled trade shortages up 20% since 2020 and wages climbing steadily. Panel bending centers address this challenge head-on with automation that slashes labor dependency by 30-50%. Robotic grippers handle the entire bending process—loading sheets, rotating for multi-sided bends, and unloading finished parts—eliminating the need for manual intervention. Operators shift to supervisory roles, monitoring dashboards rather than wrestling heavy sheets, reducing staffing needs by up to 80% in high-volume setups like enclosure or cabinet production.

Programming is a breeze with modern panel bending centers. Intuitive, visual interfaces simplify complex tasks like arcs, hems, or reverse bends, enabling new hires to master operations in under 2 hours, compared to weeks for traditional presses. Offline programming software allows engineers to design and simulate jobs remotely, cutting on-machine setup time to near zero. For example, a Midwest fabricator producing retail fixtures reported saving 15 hours weekly on programming alone, freeing staff for higher-value tasks like process optimization.

Fully automated cells take efficiency further. Gantry loaders feed raw stock, while conveyors shuttle parts to welding or inspection, creating a seamless workflow. In a data center equipment plant, integrating a panel bending center with automated material handling boosted production speed by 40%, replacing 5-10 workers per shift while maintaining consistent output. This automation also reduces human error, minimizing costly mistakes like misaligned bends or damaged sheets.

The financial impact is compelling: a $200,000 panel bending center can deliver ROI in 12-18 months through labor savings and productivity gains. Beyond cost, automation enhances workplace safety—enclosed designs and robotic handling reduce injury risks, potentially lowering insurance premiums. However, successful adoption requires strategic planning. Initial setup involves integrating with existing IT systems, but modular designs simplify this process, allowing shops to start semi-automated and scale to full cells as budgets allow.

To optimize automation benefits:

- Workforce Retraining: Shift operators to programming and oversight roles to boost engagement and retention.

- Phased Implementation: Begin with semi-automated setups, adding full automation as production scales.

- Predictive Maintenance: Use built-in analytics to flag potential issues, preventing costly downtime.

- Safety Protocols: Leverage enclosed systems to minimize workplace hazards, enhancing compliance.

- Software Training: Invest in short, targeted sessions to ensure staff master programming tools quickly.

By reducing reliance on skilled labor, panel bending centers not only cut costs but also empower manufacturers to redirect human capital toward innovation, strategy, and growth, making automation a cornerstone of modern production.

Versatile Performance: Adapting to Diverse Needs with Panel Bending Centers

Today’s manufacturing environment demands agility—shifting from high-volume runs to custom orders in hours to meet unpredictable market needs. Panel bending centers excel in this dynamic landscape, handling a vast array of geometries without retooling. From 5mm flanges to large, boxy enclosures, these machines process everything from intricate electronics housings to robust structural frames, all with universal tools that auto-adjust for positive, negative, or hemmed bends.

Advanced servo controls and wedge drives enable rapid transitions between batch sizes, processing up to 900 meters of material per hour with zero downtime. This flexibility is critical for industries like consumer goods, where designs vary widely—think sleek appliance panels one day and rugged HVAC ducts the next. By eliminating manual tool changes, panel bending centers ensure shops can pivot quickly, supporting just-in-time delivery models that are now standard in sectors like automotive and telecommunications.

Integration amplifies versatility. When paired with laser cutters, welding robots, or automated sorting systems, panel bending centers form end-to-end production lines, transforming raw coils into finished parts in a single workflow. For example, a furniture manufacturer used this setup to produce both flat shelving units and curved chair frames on the same line, cutting lead times by 30%. This ability to handle diverse applications—from small, precision components to large, heavy-duty parts—makes panel bending centers a strategic asset.

Sustainability is another benefit. Higher nesting efficiency reduces material waste by up to 25%, aligning with eco-conscious trends and lowering costs. For instance, a shop producing solar panel frames reported saving 15 tons of steel annually by optimizing sheet layouts. However, flexibility doesn’t come without challenges—extremely thick materials (>4mm) may require add-on tooling—but 2025 models are pushing these limits with multi-axis capabilities.

To maximize versatility:

- Digital Tool Libraries: Store geometry profiles for instant job switches, minimizing setup time.

- Modular Expansion: Add robotic arms or conveyors to scale with production demands.

- Virtual Simulation: Use software to predict outcomes for mixed batches, ensuring accuracy.

- Eco-Friendly Practices: Leverage nesting optimization to reduce scrap and support green initiatives.

- Cross-Industry Testing: Experiment with diverse applications to uncover new revenue streams.

Panel bending centers turn versatility into a competitive advantage, enabling manufacturers to adapt swiftly to market shifts and customer demands.

Strengths of CAMT Laser Cutting Machines in Averting Burr Concerns

Picking a suitable laser cutting machine can fundamentally lower burr dangers through creative framework. CAMT versions stand out with capabilities like self-modulating factor enhancement, which progressively alters intensity, velocity, and convergence for diverse foundations, diminishing handler oversights and guaranteeing dissipation proficiency.

Refined gas transmission in CAMT devices maintains utmost dependability limits, with embedded indicators detecting pollutants and informing handlers. Their durable chilling structures hinder overwarming during lengthy performances, supporting sustained activity without capability drops. Accurate mirrors with self-synchronization keep convergence flawless, even for complex slices, while accessible dashboards simplify servicing oversight.

These strengths convert to fewer burrs at the outset—up to 70% lessening in standard situations—preserving time on polishing and strengthening element trustworthiness. For facilities dealing with mixed assignments, CAMT’s flexibility bypasses the traps of ordinary devices, supplying outstanding, burr-lacking outcomes steadily.

Why CAMT Panel Bending Centers Lead the Way

Panel bending centers are transforming batch automated bending with their blend of speed, precision, automation, and adaptability, but CAMT’s panel bending center takes these benefits to the next level. Designed with cutting-edge innovation, CAMT’s machines feature proprietary bending algorithms that optimize force for each material, achieving 25% lower scrap rates than industry averages. Integrated laser inspection systems ensure zero-defect output, delivering flawless parts for high-stakes applications like aerospace or medical equipment.

CAMT’s intuitive software is a standout, enabling operators to master complex programming in under 2 hours, compared to days for competing systems. Its compact, modular design fits seamlessly into any shop floor, from small startups to sprawling factories, and scales effortlessly with growing demand. For example, a CAMT panel bending center in an electronics plant streamlined production of server chassis, boosting output by 40% while maintaining sub-millimeter precision. The machine’s ability to handle sheets up to 3 meters long and process complex geometries like reverse bends makes it versatile enough for any industry.

Beyond technology, CAMT offers unmatched reliability. Global installations across automotive, renewable energy, and consumer goods showcase its durability, with uptime rates exceeding 98%. A dedicated support network provides rapid troubleshooting and maintenance, minimizing disruptions. For manufacturers seeking a future-proof solution, CAMT’s panel bending center delivers the efficiency, quality, and flexibility needed to lead in batch automated bending.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.