How to Diagnose and Repair Press Brake Cylinder Failures

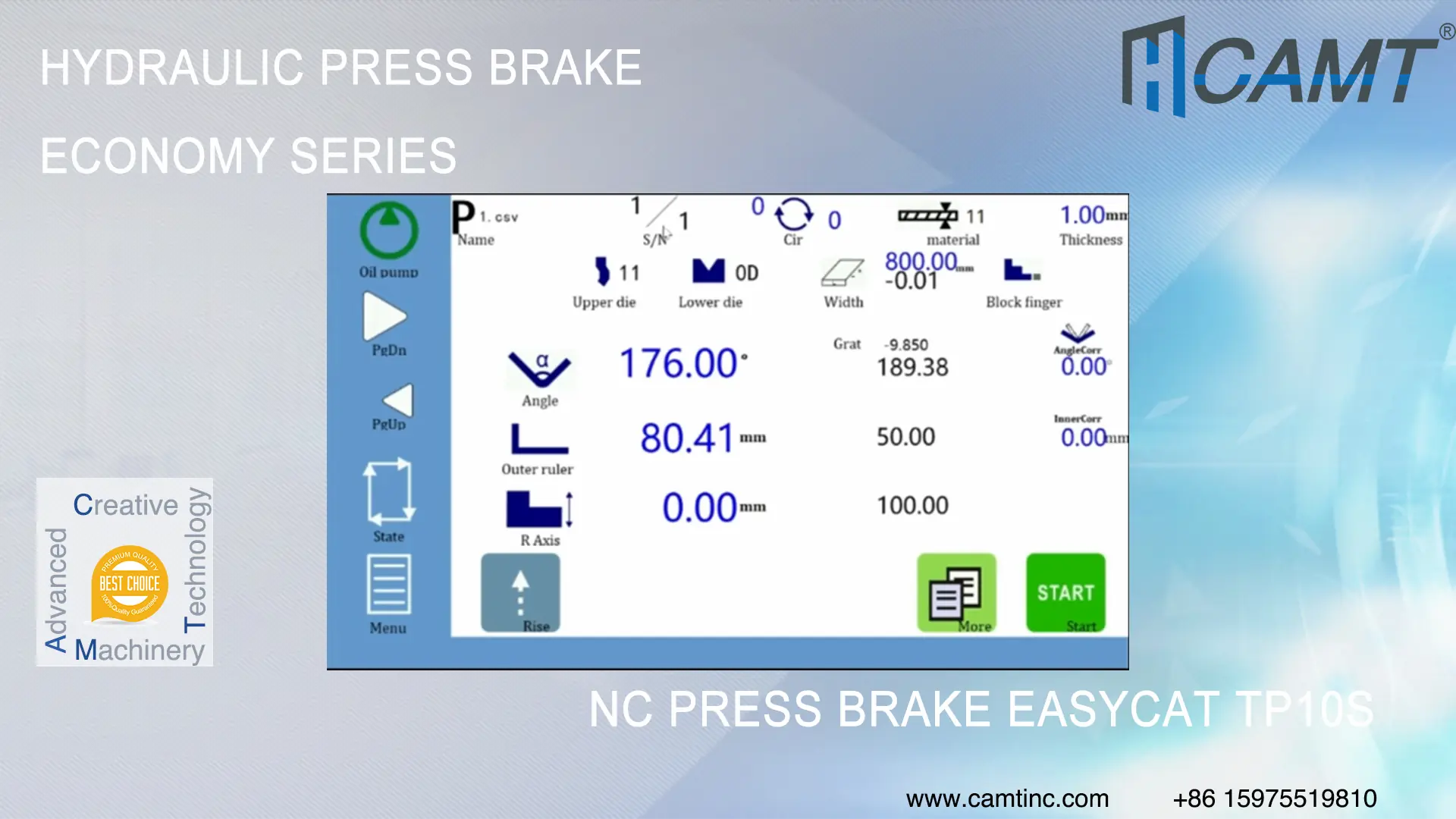

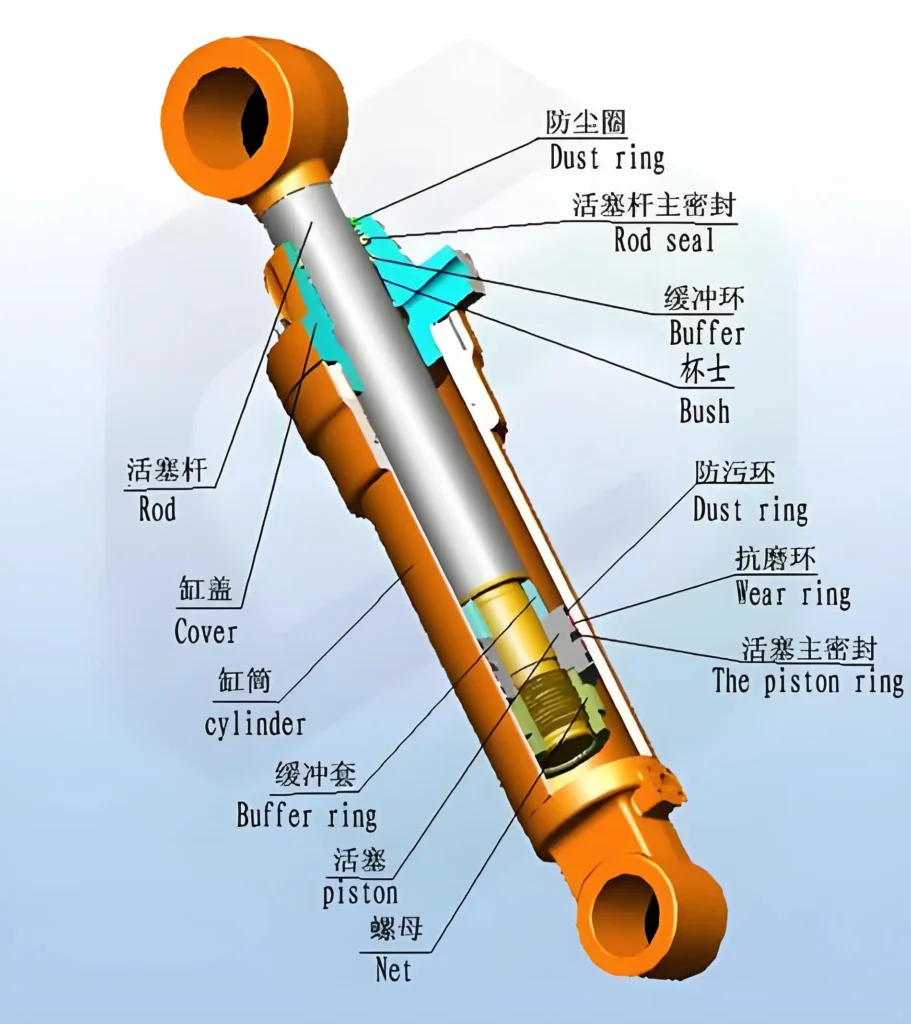

Hydraulic press brake cylinder is the powerhouse behind hydraulic and electro-hydraulic CNC press brakes. It transforms hydraulic energy into mechanical force, driving the ram’s linear motion to shape metal sheets with precision. In sheet metal fabrication, the cylinder’s performance determines the machine’s ability to deliver consistent, high-quality bends. This comprehensive guide dives into the critical role of press brake cylinders, common failure causes, detailed repair methods, synchronization solutions for CNC press brakes, and a robust maintenance plan to maximize uptime and efficiency.

Why Press Brake Cylinders Are Critical

The hydraulic press brake cylinder is the backbone of bending operations, influencing performance in several key areas:

Power and Pressure Delivery

Cylinders channel hydraulic fluid to move the piston rod, enabling the ram to exert the force needed for bending. In hydraulic press brakes, dual cylinders mounted on the machine frame ensure uniform pressure distribution for precise sheet metal forming. For example, a 100-ton press brake relies on cylinders to deliver up to 1000 kN of force, critical for thick or high-strength materials. Without reliable cylinders, the machine cannot achieve its rated tonnage, halting production.

Precision and Operational Efficiency

Cylinder performance governs bending accuracy, force consistency, and cycle speed. In electro-hydraulic CNC press brakes, advanced servo-controlled cylinders enable micro-adjustments, achieving tolerances as tight as ±0.01 mm. Hybrid press brakes, for instance, use high-speed cylinder designs to increase bending cycles by up to 30% compared to traditional models, boosting throughput in high-volume shops.

Reliability and Cost Efficiency

As a critical hydraulic component, the cylinder’s piston assembly dictates the machine’s failure rate and longevity. High-quality cylinders reduce energy losses by up to 15% through optimized sealing and stroke control, minimizing oil leaks and maintenance costs. They also support adjustable stroke lengths, enhancing versatility for diverse workpieces and reducing setup times.

The press brake cylinder is thus the “heart” of the machine, directly impacting product quality, operational stability, and cost-effectiveness in sheet metal processing.

Common Press Brake Cylinder Failures and Their Impact

Substandard cylinders or poor maintenance can trigger cascading issues, affecting production and safety. The table below outlines failure types, their manifestations, and consequences, based on industry observations:

Failure Type | Manifestation | Consequences |

Mechanical Failure | Ram desynchronization, inability to raise/lower, or cylinder deformation; restricted stroke adjustment. | Inaccurate bends, defective parts, frequent downtime (costing $500-$2000/hour in lost production), and higher repair expenses. |

Hydraulic System Issues | Oil leaks, overheating (e.g., fluid >60°C), pressure fluctuations, or complete pressure loss; seal degradation causing contamination. | Environmental hazards, fire risks, 20-30% efficiency drops, accelerated wear, and reduced machine lifespan by up to 50%. |

Production Impact | Inconsistent bend angles (±2° deviations), slow cycle times (e.g., 50% reduced speed), frequent full-load failures. | Batch rejections (up to 10% scrap rates), delayed deliveries, and financial losses from rework or penalties. |

Safety and Maintenance Risks | Uncontrolled oil leaks, pressure surges, or excessive fluid temperatures. | Explosion or fire hazards, operator injuries, and contamination from improper maintenance, increasing repair costs by 25-40%. |

These failures often result from low-quality materials, design flaws, or neglected maintenance, amplifying issues across the hydraulic system.

Types of Bending Tools and Their Characteristics

The worktable length dictates the maximum workpiece size that can be processed. Common CNC press brakes offer worktable lengths from 1.5 to 4 meters, suitable for various sheet metal sizes. Selecting an appropriate worktable length ensures adequate support for the workpiece, preventing deformation due to overhang. For oversized workpieces, segmented bending may be necessary, requiring careful planning of the bending sequence to maintain accuracy. Proper pressure and worktable length settings lay the foundation for effective tool selection and process optimization.

Causes of Press Brake Cylinder Sticking

Cylinder sticking disrupts operations and reduces precision. Common causes include:

Contamination Build-Up

Over time, dirt, metal particles, and sludge accumulate on cylinder walls and pistons, increasing friction and causing sticking. For example, a 2023 case study of a 200-ton press brake showed a 25% performance drop due to unfiltered hydraulic fluid.

Air Bubbles in the System

Air trapped in hydraulic lines creates cavitation, disrupting fluid flow and causing erratic or stalled cylinder movement. This is common in systems with loose fittings or inadequate bleeding.

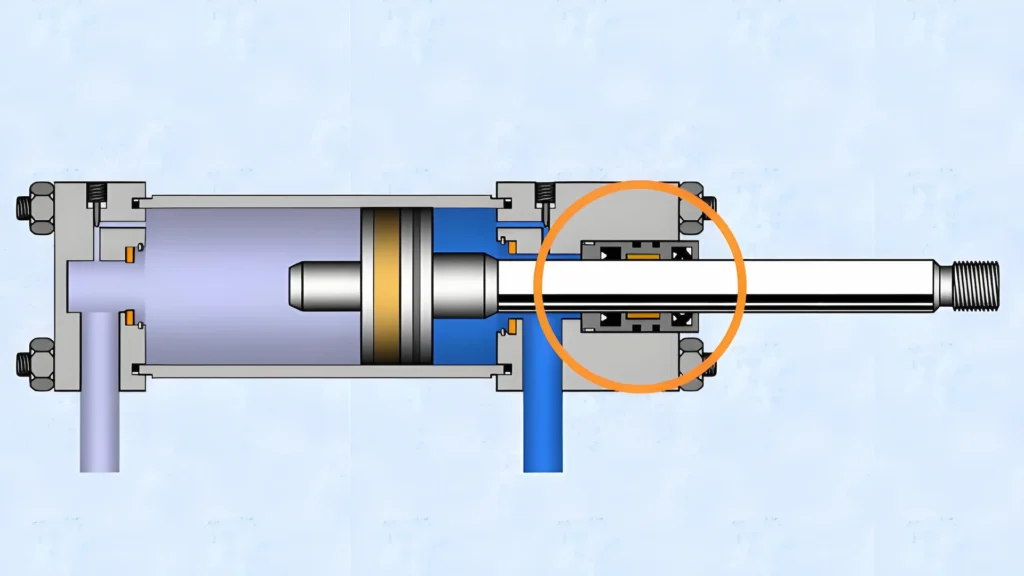

Poor Sealing

Worn or low-quality seals lead to hydraulic fluid leaks, reducing pressure and causing pistons to stick. A single seal failure can result in 10-15% efficiency losses.

Hydraulic System Failures

Faulty pumps, clogged valves, or pressure regulator issues can starve the cylinder of consistent fluid flow, leading to sticking or complete failure.

Solutions for Press Brake Cylinder Sticking

Effective repairs restore functionality and prevent recurrence. Here are detailed solutions:

Cylinder Cleaning

Process: Disassemble the cylinder, clean inner surfaces and pistons with industrial-grade solvents, and inspect for wear.

Tools: Use ultrasonic cleaners for thorough debris removal.

Frequency: Every 6 months or 2000 operating hours.

Case Study: A fabrication shop reduced downtime by 30% after implementing quarterly cylinder cleanings.

Air Bleeding

Process: Install bleed valves at system high points and cycle the system to expel air. Verify with a pressure test.

Tools: Use a vacuum pump for faster air removal in large systems.

Tip: Check for air ingress at pump suction lines or fittings.

Seal Replacement

Process: Replace worn seals with high-quality, OEM-specified materials (e.g., polyurethane seals for high-pressure systems).

Cost: $50-$200 per cylinder, depending on size.

Impact: Restores full pressure and prevents leaks, improving efficiency by up to 20%.

Hydraulic System Inspection

Process: Test pumps, valves, and filters for blockages or malfunctions. Replace faulty components and flush the system.

Tools: Use a hydraulic diagnostic kit to measure flow and pressure.

Example: A 2024 repair on a CNC press brake resolved a pump failure, restoring 95% of original performance.

Regular maintenance, such as monthly fluid checks and annual system overhauls, prevents sticking and extends cylinder life by 2-5 years.

System Solutions for CNC Press Brake Cylinder Synchronization

Desynchronization in electro-hydraulic CNC press brakes causes uneven bends and production delays. A multi-faceted approach is needed:

Hydraulic System Troubleshooting

Hydraulic Fluid Check

Ensure fluid cleanliness (ISO 4406 standard: 16/14/11 or better).

Replace contaminated oil or clogged filters (cost: $100-$300).

Maintain oil temperature below 60°C to preserve viscosity, using coolers if needed.

Servo and Proportional Valve Inspection

Clean or replace clogged/worn servo valves ($200-$500).

Calibrate zero points and gain settings using a digital controller.

Example: A 2025 repair case fixed a 0.5mm desynchronization by recalibrating servo valves.

Cylinder Leak Detection

Conduct a 5-minute pressure-holding test (e.g., at 200 bar).

Replace seals or cylinders if pressure drops >5%.

Inspect pipelines for external leaks with UV dye tracing.

Pressure and Flow Balance

Verify pump output stability (±2 bar).

Adjust flow-dividing valves or install pressure compensators to balance oil supply.

Impact: Reduces synchronization errors to <0.1mm.

Mechanical Component Inspection

Guide Rail and Ram Check

Clean rails with degreasers and inspect for wear or scratches.

Adjust rail-ram clearance to 0.05-0.1mm for smooth motion.

Cost: $100-$500 for rail repairs.

Load Balance Verification

Ensure molds are level using a laser alignment tool.

Position workpieces symmetrically to prevent single-sided loading.

Electrical Control Calibration

Sensor Signal Check

Clean position sensor heads and recalibrate zero points.

Use shielded cables to eliminate signal interference.

Controller Parameter Tuning

Optimize PID settings (e.g., proportional gain: 0.8-1.2, integral time: 0.1-0.2s).

Implement master-slave or cross-feedback algorithms for real-time synchronization.

System Testing and Validation

Manual Mode Testing

Drive each cylinder individually, monitoring pressure with a gauge (±1 bar tolerance).

Adjust valves to equalize pressures.

Automatic Mode Calibration

Run self-learning cycles to set synchronization baselines.

Use diagnostic software to monitor displacement curves, targeting <0.1mm error.

Preventive Maintenance Schedule

Task | Frequency | Cost Estimate | Impact |

Replace hydraulic oil and filters | Every 6 months | $200-$500 | Reduces contamination by 80% |

Inspect servo valve response | Quarterly | $100-$300 | Prevents 90% of valve-related failures |

Lubricate mechanical components | Monthly | $50-$150 | Extends component life by 30% |

Log and analyze fault data | Monthly | $0 (in-house) | Predicts 70% of potential failures |

FAQ: Press Brake Cylinder Failure Diagnosis and Solutions

Q: What are the main causes of press brake cylinder failure?

A: Valve core sticking, blockages, low control pressure, air in the system, or high fluid viscosity in cold conditions.

Q: How do I fix a stuck valve core or blocked valve hole?

A: Check fluid for contamination, clean or replace the valve core, and inspect valve body wear.

Q: Why does the cylinder not move or move slowly?

A: Inspect for tight seals, contamination, or misalignment. Replace worn seals and ensure proper cylinder alignment.

Q: How can I address low hydraulic pressure?

A: Adjust throttling resistance, verify valve settings, and check pressure source for interference.

Q: How do I prevent air in the hydraulic system?

A: Monitor fluid levels, inspect pump suction seals, and clean/replace coarse filters.

Q: Why is cylinder performance poor in cold conditions?

A: High fluid viscosity reduces flow. Use low-viscosity hydraulic oil or preheat the system with a heater.

Q: How often should I maintain my press brake cylinder?

A: Follow a quarterly maintenance schedule, including fluid checks, seal inspections, and valve calibrations.

Conclusion

Press brake cylinder maintenance is a cornerstone of reliable sheet metal fabrication. By addressing failure causes like contamination, air bubbles, and seal issues, and implementing systematic synchronization solutions, operators can achieve near-perfect bending accuracy and efficiency. Regular maintenance, supported by data-driven schedules and professional services like CAMT, can extend equipment lifespan by 3-7 years and reduce downtime costs by up to 40%. Invest in high-quality components and proactive care to keep your hydraulic or CNC press brake performing at its best.

Metalworking specialist with 12 years of experience in sheet metal fabrication and press brake applications, certified by ASME.