Principle and Function of Press Brake Safety Protection System

Malawi

Malta Marshall Islands Mauritania.

Mauritius.

Mexico

Micronesia.

Moldova

Monaco

- Mongolia

- Montenegro

Morocco.

Mozambique

Myanmar Namibia.

Nauru Nepal.

Netherlands New Zealand.

Nicaragua.

Niger

Nigeria.

North Macedonia

- Norway

- Oman

- Pakistan

Palau.

Panama

Papua New Guinea.

Paraguay

Peru.

Philippines.

Poland.

Portugal

Qatar.

Romania.

Russia.

Rwanda

Saint Kitts and Nevis.

Saint Lucia

- Saint Vincent and the Grenadines

- Samoa

- San Marino

Sao Tome and Principe.

Saudi Arabia

Senegal.

Serbia

Seychelles.

Sierra Leone.

Singapore.

Slovakia

Slovenia.

Solomon Islands.

Somalia

South Africa.

South Sudan

Spain.

Sri Lanka.

Sudan

Suriname.

Sweden.

Switzerland

Syria.

Tajikistan.

Tanzania.

Tajikistan

Timor-Leste.

Togo.

Tonga

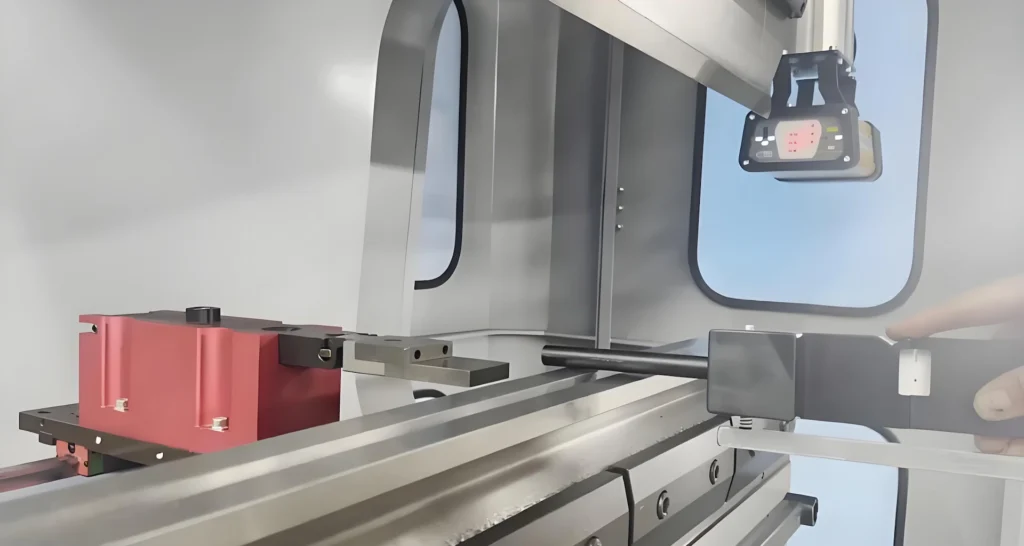

Q1: What is press brake safety protection?

Press brake safety protection refers to systems designed to prevent operator injury during bending operations, typically using sensors, light curtains, or dynamic detection technology.

Q2: How does DSP differ from traditional light curtains?

Unlike static light curtains, DSP systems create a dynamic detection zone that moves with the ram, offering better protection and fewer false stops.

Q3: Is DSP press brake safety suitable for small or complex parts?

Yes. Special operating modes allow controlled operation while maintaining protection near the punch tip.

Q4: Does masking detection zones reduce safety?

When applied correctly and based on risk assessment, selective masking improves usability without compromising operator safety.

Q5: Can DSP systems help meet CE and ISO safety standards?

Yes. DSP press brake safety systems are designed to support compliance with major international safety regulations.