CAMT

Economy Torsion Bar Bending Machine 2-3 Axis

CAMT

CAMT Most Economic Simple Press Brake

Cheapest Bending Solution With Competive Pricing & Preferential Quality

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Industry 4.0 Ready

New Design

High Performances

Green Hybrid Servo

Environmentally Friendly

Quiet Operation

Popular Configuration

- Estun full series NC system for selection

- Standard for EASYCAT TP10S 3+1 Axis

- Siemens powerful main motor

- USA HYTEK/SUNNY oil pump

- Multi V Die square mould

- Y1 Y2 ajustment seperately

- Double linear guide & ball Screw

- France Schneider Electric Parts

- EASYCAT sensitive Sonsor

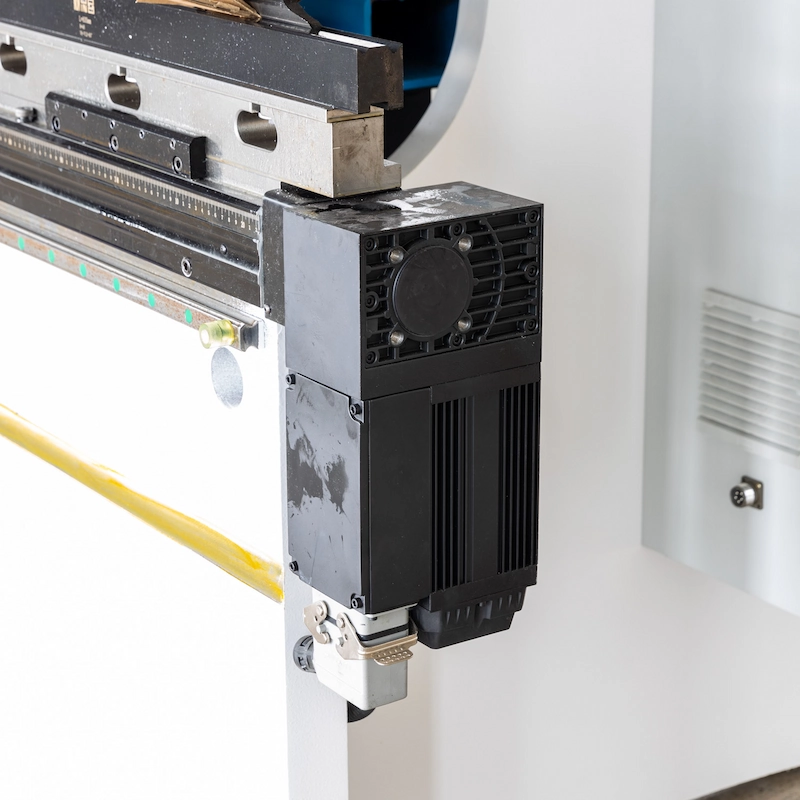

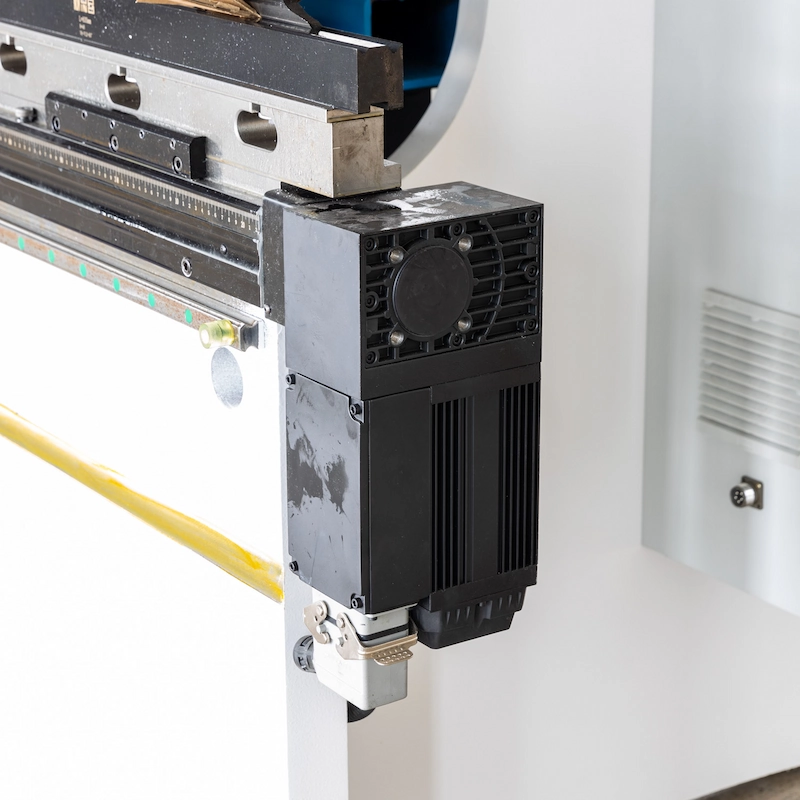

- Servo Backgauge & Drive

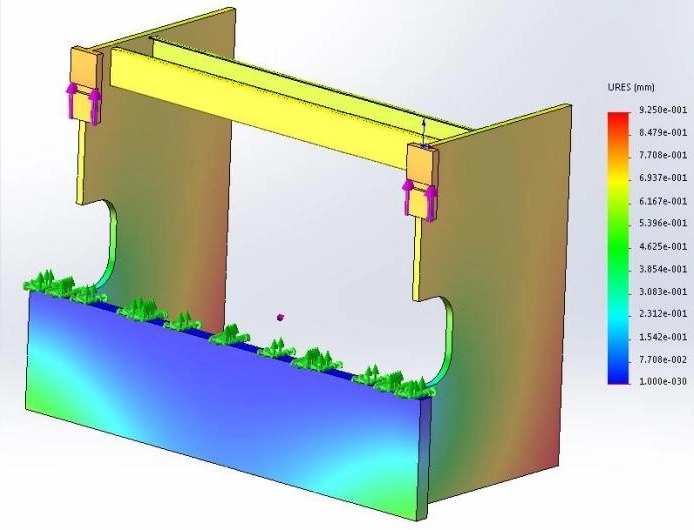

FEA & Stress Analysis of Press Brake

Stress Analysis & Finite Element Analysis

CAMT FEA plays a pivotal role by optimizing structures through stress distribution analysis to identify and reinforce high-stress areas, enhancing strength while minimizing material waste; verifying performance by predicting deformation under extreme loads (e.g., 600 tons) to ensure precision and stability for Y1/Y2 synchronization; assessing safety by evaluating stress concentration to mitigate fatigue or fracture risks for long-term reliability; and conducting dynamic analysis to simulate transient loads and vibrations in complex scenarios like tandem bending or high-speed operations, optimizing servo motor response and overall machine stability.

Popular NC Control System Press Brake Machine

EASYCAT TP10S CONTROL SYSTEM

ESTUN Full Series NC Controller Widely Choice

Traditional Digital Screen E21 System

- Positioning control of back gauge

- Intelligent positioning control

- Unilateral and bidirectional positioning which eliminates spindle clearance effectively

- Retract functions

- Automatic reference searching

- One-key parameter backup and restore

- Fast position indexing.

- 40 programs storage space, each program has 25 steps

- Power-off protection

Main Motor & Oil Pump

Siemens Powerful Main Motor & USA HYTEK Oil Pump

- High efficiency and stable performance, providing consistent and reliable power output, reducing equipment failure rates.

- The fast response and accurate pressure control of HYTEK oil pumps, combined with the efficient drive of renowned main motors, enhance the processing accuracy of torsion bar bending machines, meeting the demands of complex workpiece forming

- HYTEK oil pumps are made with high-quality materials and advanced manufacturing processes, offering long service life, reducing replacement frequency, and lowering maintenance costs, thus improving overall economic efficiency.

- energy-efficient designs, reducing power consumption. HYTEK oil pumps operate with high hydraulic efficiency, minimizing oil waste and aligning with modern manufacturing’s green production standards.

- Readily available spare parts. They are highly compatible with other components of torsion bar bending machines, facilitating upgrades and maintenance.

Hydraulic System of Hydraulic Press Brake

TAIWAN UOSHEN-Stability & Good Performance Pressure Valve

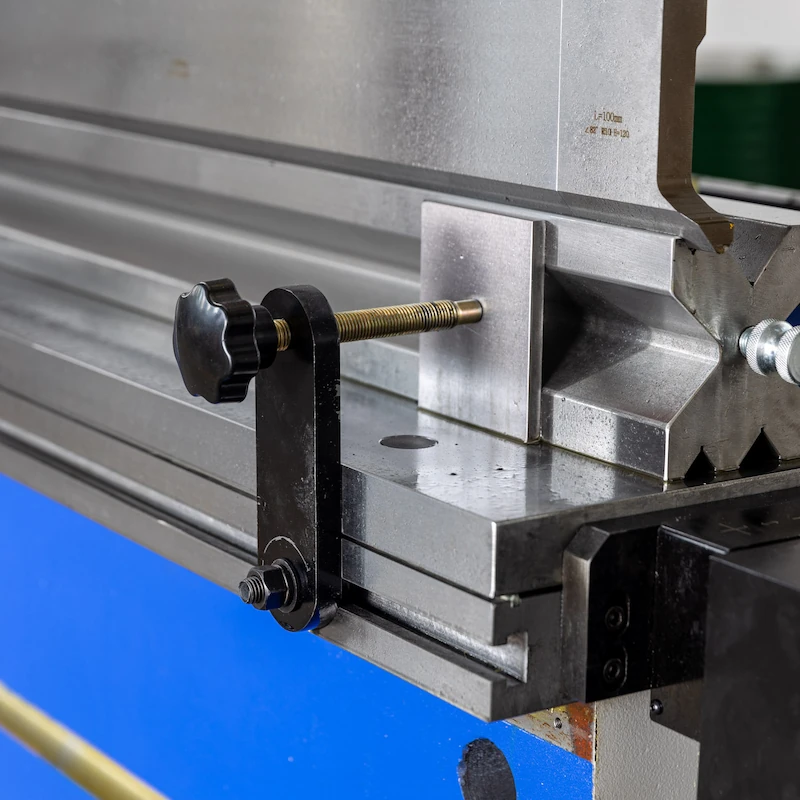

Torsion Shaft Structure

Advantages:

- Enhanced Equipment Stability

- Simplified Control System

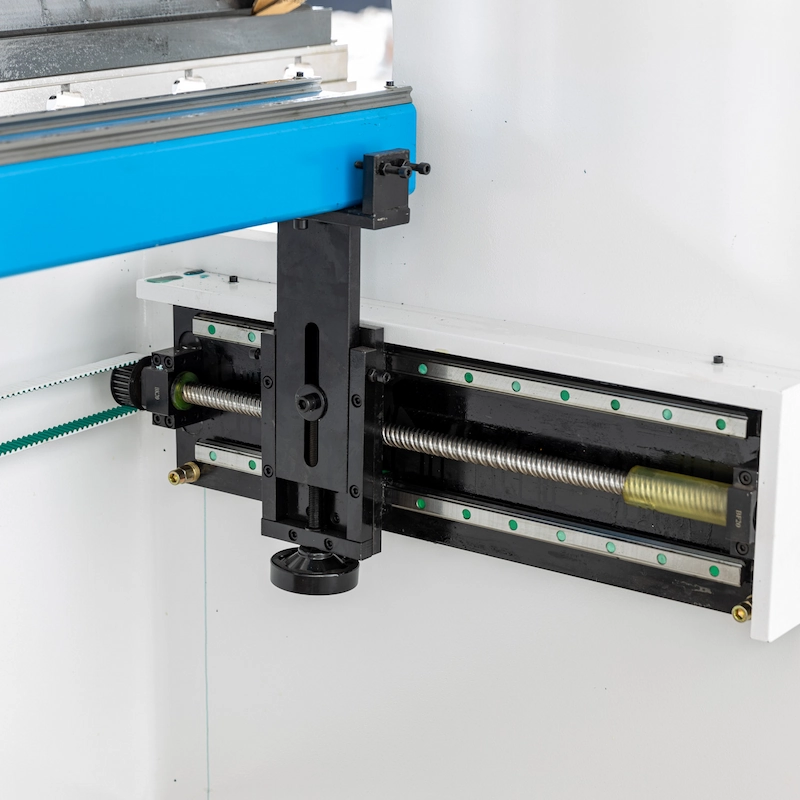

Taiwan Double Linear Guide & Ball Screw

Advantage:

- High-Precision Motion

- Enhanced Stability

- Fast Response

- Adaptability to Complex Processing Needs

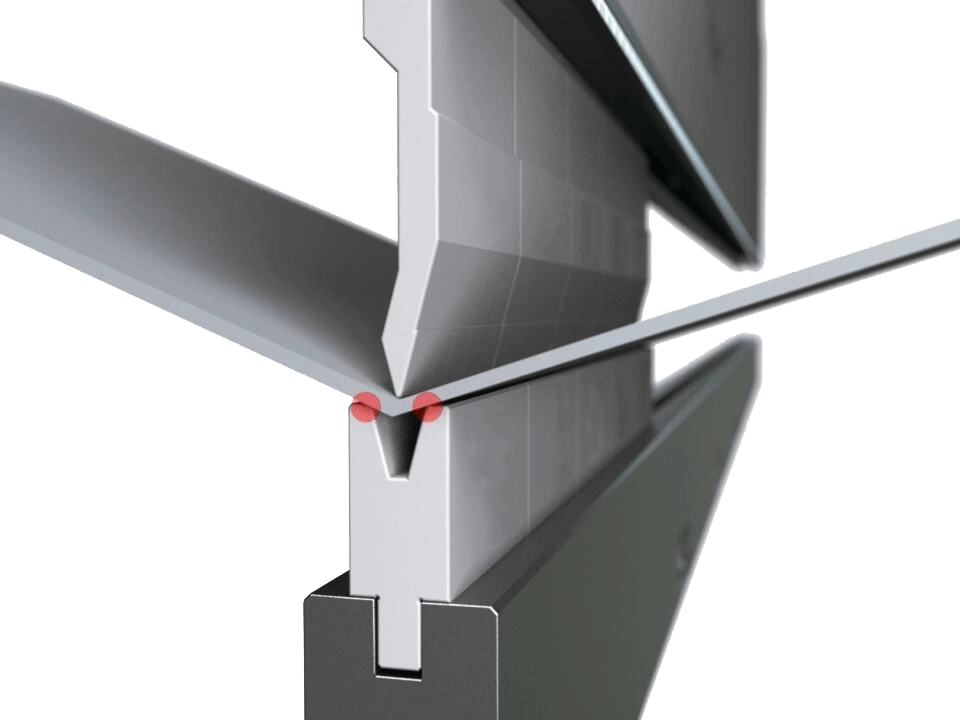

Precise Hydraulic Press Brake Oil Cylinder & Sensor

Advantage:

- Improved Synchronization

- Enhanced Equipment Reliability

- Fast Response and Efficiency

- Ease of Automation Integration

Electric Motorized Crowning of Press Brake Machine

Electric System for Hydraulic Press Brake

France Schneider Electrics & Servo Drive

Customized Press Brake Tooling

Advantage:

- feature a simple structure, with low manufacturing and maintenance costs

- Stable operation and low failure rates, suitable for continuous, long-term production

- Easy to operate and maintain

- Demands of standard sheet metal processing

- offering broad application versatility

- Compatible with automation control systems and inductive switches

- Boast long-lasting, robust parts durability