Traditional ARC Welding

ULT Professional Pipe Laser Cutting Machine

Traditional ARC Welding

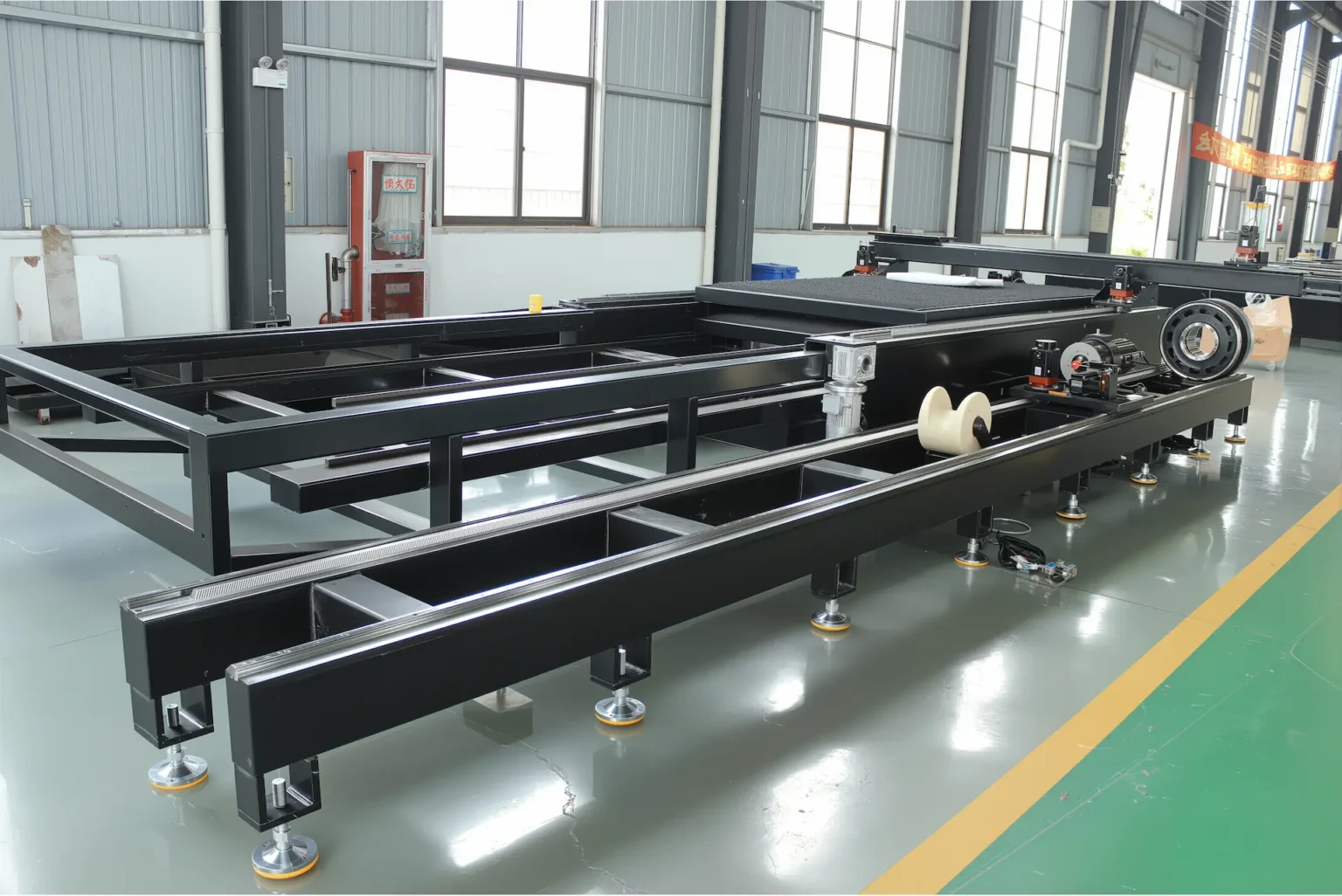

Professional Dual Use Plate & Tube Laser Cutting Solution

Features a Japanese servo drive system for rapid, energy-saving cuts that boost productivity."

Flawless Cutting.

ULT Professional Pipe Laser Cutting Machine

40X40

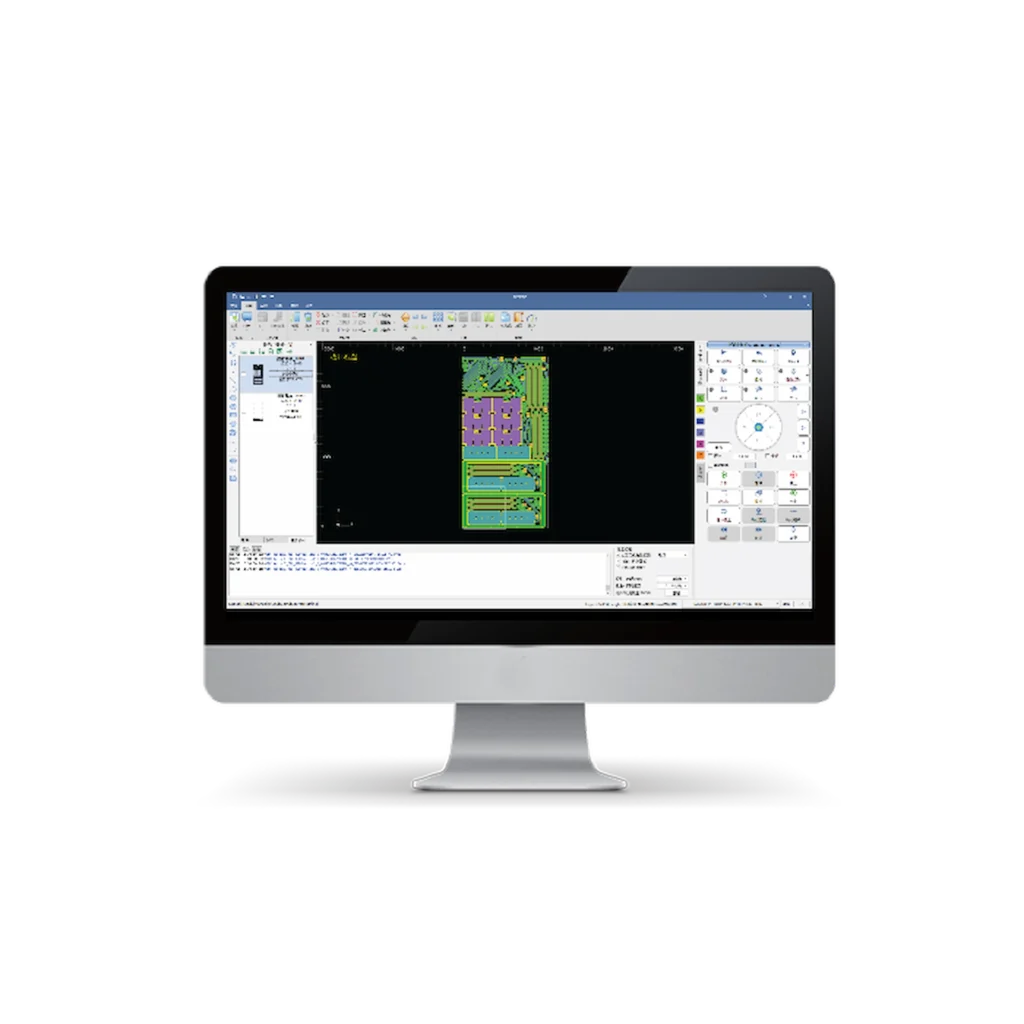

Professional Laser Cutting Control System

Integrates file reading, design output and processing control. A set of software can complete the whole process from design to processing.

Based on Windows operation development

Support a variety of file rich layer interface.

Simple and practical cutting software

Real-time frequency and power curve.

Most Popular RAYCUS Laser Source

Using ytterbium (Yb)-doped fiber as the gain medium, pumped by semiconductor laser diodes to generate high-power laser beams.

No

Welding speed

2 Times Welding.

consumables

Operation difficulty.

Hard

Welding fault tolerance.

Swing welding

No/Expensive.

Standard

Worker safety design.

Humanized design, more practical user experience. Simple operation The control system is simple to operate and easy to learn with more comprehensive compatibility, more flexible and effective processing. High precision, with high production and processing quality.

Processing can carry out multi axis coordination, easily produce complicated designs. When machining parts are changed, generally only a program be written, which can save production site management time and save human capital work.

- The rigidity is large and the output rate is high; the feeding and unloading is very convenient and can alleviate the labor efficiency.

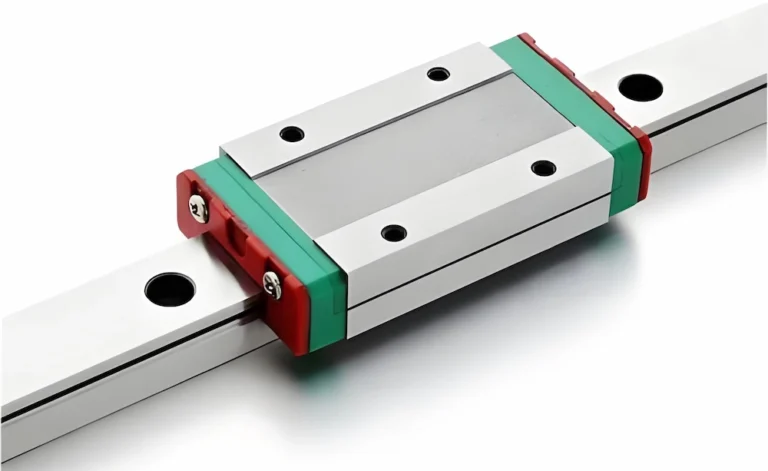

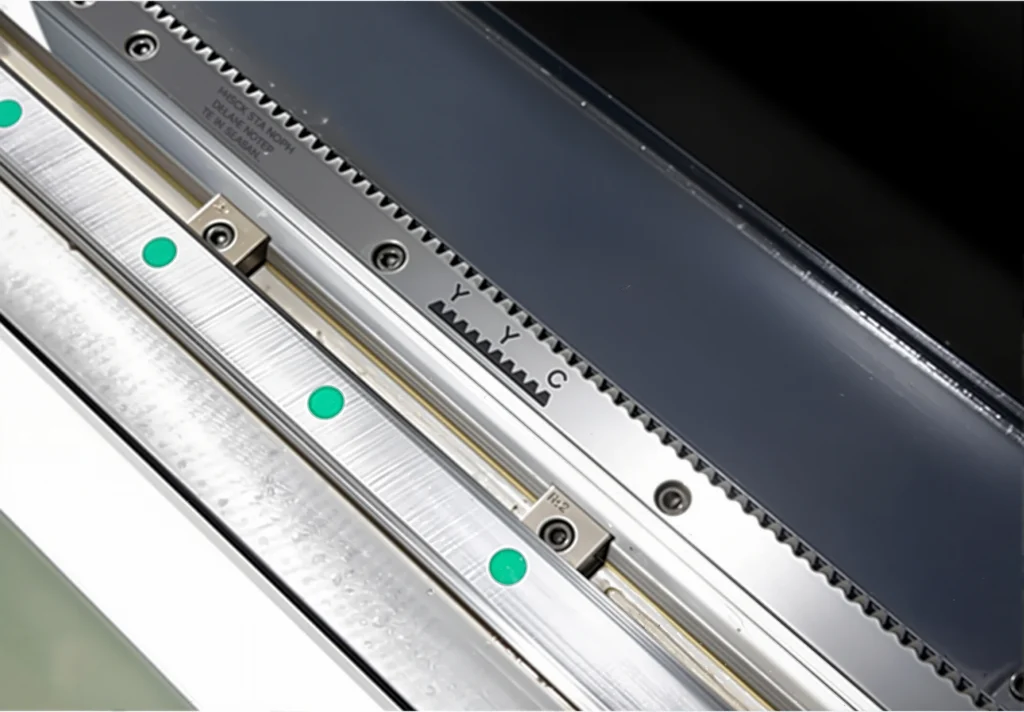

- Enhanced Precision and Stability

- HIWIN guides ensure μm-level accuracy with low-friction rolling motion, while YYC racks (European Grade 6) minimize backlash for consistent, high-quality cuts.

- Improved Efficiency and Speed

HIWIN’s low-friction design enables rapid, slip-free motion, and YYC racks support high-speed linear motion, boosting productivity.

Durability and Longevity.

HIWIN guides, with 70 HRC hardness, resist wear, and YYC racks endure heavy loads, ensuring long-term reliability in tough conditions.

Versatility Across Applications.

HIWIN guides handle multi-directional loads and self-align, while YYC racks (straight/helical) suit various machines, offering flexibility.

INOVANCE Servo Motors & Drivers for Fiber Laser Cutter.

Ensuring accurate laser beam movement for complex sheet or tube processing, while enhancing dynamic response and multi-axis coordination.

Precise Motion Control.

High-Speed Performance

Enhanced Stability and Smooth Operation.

Energy Efficiency and Low Heat Generation

Reliability and Low Maintenance

Stability and Durability

Strong Adaptability

HANLI Cooling System for Laser.

Cooling systemhas good quality and high temperature control accuracy; stable and reliable performance, low failure rate, energy saving and power saving; personalized design, etc.

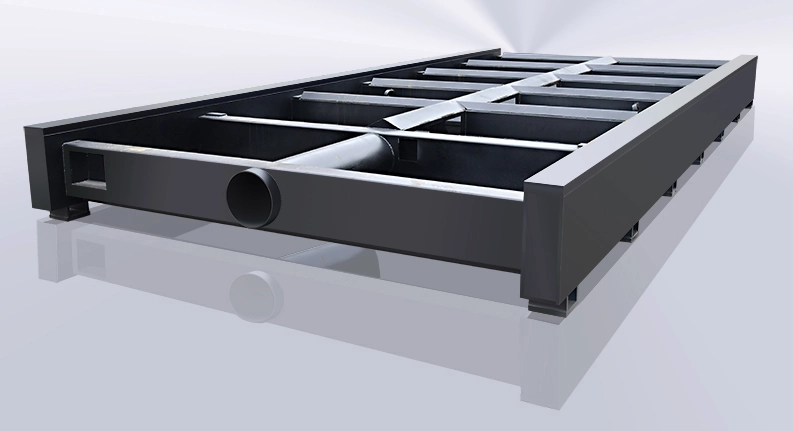

Superior Performance Parts for Stability.

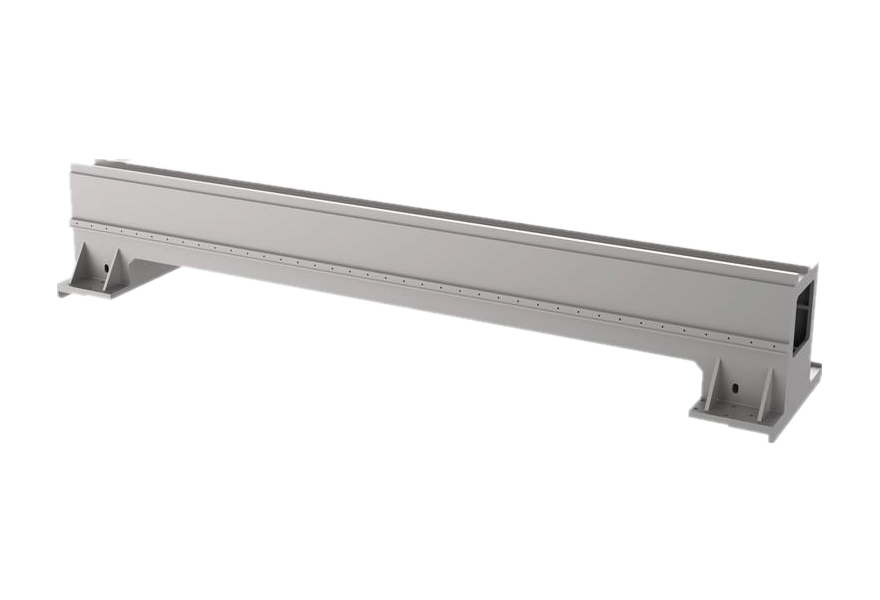

Using honeycomb structure beam design high strength, high rigidity, light weight

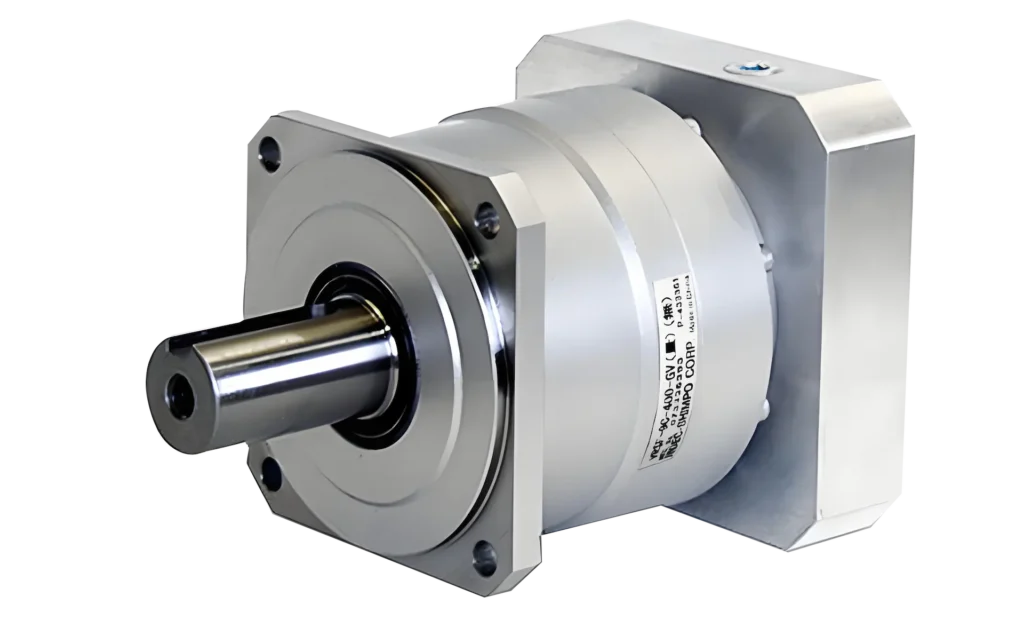

SHIMPO reducer with high precision, silent, long life, no oil leakage, large torque and other fine characteristics.

- CAMT Laser Cutting Machine Quality.

- CAMT made by laser cutting can basically be used only once, and can be used directly without other post-processing, so that the processing technology of the product has been well optimized. In addition, the edges of the cut product will not have sags or burrs, and the surrounding thermal deformation is relatively small, so small that it can be ignored.

- By understanding the advantages of laser cutting, we know that many processing advantages cannot be achieved by traditional mechanical processing, and these advantages of laser cutting are exactly what we need for processing now, so laser cutting just goes with the flow. It has become the most popular and most used processing method in the processing industry.

High Performance Technical Specification of CAMT Laser

Parameter.

Max. Running Speed 120M/MIN

X/Y Location Precision 0.01MM.

X/Y Repeated Location Precision 0.03MM

Machine Gross Power <10KVA.

Running Humidity < 90%

Max. Accelerated Speed 1.5G.

Dual Use Plate and Pipe Laser Cutting Application

Tube-sheet integrated fiber laser cutting machine is a high-performance fiber laser cutting machine specially developed and designed for users in various industries of tube and sheet metal processing.

Special tools mode

- It can cut plate and pipe, which greatly saves labor cost and machine cost and improves quality.

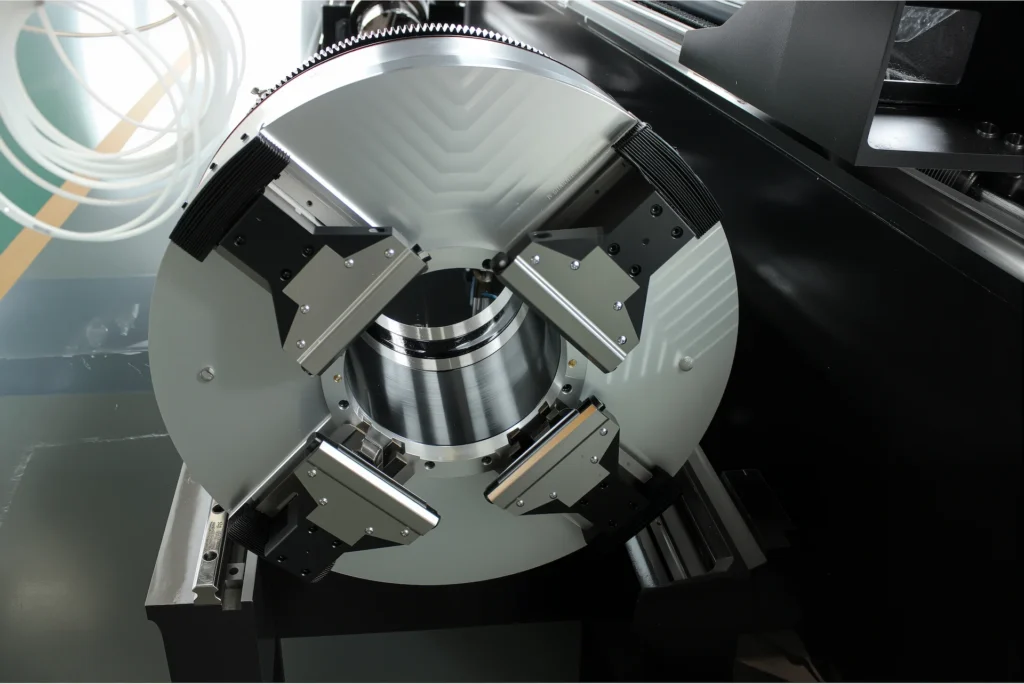

- Professional Chuk For Pipe and Tube

- CAMT adopts rack and pinion transmission structure, standard manual clamping chuck, push-type pipe cutting method, can be used for general sheet metal cutting and common square tube, round tube, rectangular tube cutting.

- Powerful cutting function can meet customers’ flat and pipe cutting requirements at the same time.

- It adopts manual chuck and push-type cutting method, which has high centering precision and processing precision.

- ULT Tube And Pipe Variety Shapes

- breadcrumbs

HANLI Cooling System for Laser

Cooling systemhas good quality and high temperature control accuracy; stable and reliable performance, low failure rate, energy saving and power saving; personalized design, etc.

Superior Performance Parts for Stability

- Using honeycomb structure beam design high strength, high rigidity, light weight

- SHIMPO reducer with high precision, silent, long life, no oil leakage, large torque and other fine characteristics.

CAMT Laser Cutting Machine Quality

CAMT made by laser cutting can basically be used only once, and can be used directly without other post-processing, so that the processing technology of the product has been well optimized. In addition, the edges of the cut product will not have sags or burrs, and the surrounding thermal deformation is relatively small, so small that it can be ignored.

By understanding the advantages of laser cutting, we know that many processing advantages cannot be achieved by traditional mechanical processing, and these advantages of laser cutting are exactly what we need for processing now, so laser cutting just goes with the flow. It has become the most popular and most used processing method in the processing industry.

High Performance Technical Specification of CAMT Laser

Parameter

- Max. Running Speed 120M/MIN

- X/Y Location Precision 0.01MM

- X/Y Repeated Location Precision 0.03MM

- Machine Gross Power <10KVA

- Running Humidity < 90%

- Max. Accelerated Speed 1.5G

Dual Use Plate and Pipe Laser Cutting Application

- Tube-sheet integrated fiber laser cutting machine is a high-performance fiber laser cutting machine specially developed and designed for users in various industries of tube and sheet metal processing.

- It has many technical advantages such as high configuration, high cutting efficiency, low operating cost and stable performance.

- It can cut plate and pipe, which greatly saves labor cost and machine cost and improves quality.

Professional Chuk For Pipe and Tube

- CAMT adopts rack and pinion transmission structure, standard manual clamping chuck, push-type pipe cutting method, can be used for general sheet metal cutting and common square tube, round tube, rectangular tube cutting.

- Powerful cutting function can meet customers’ flat and pipe cutting requirements at the same time.

- It adopts manual chuck and push-type cutting method, which has high centering precision and processing precision.

ULT Tube And Pipe Variety Shapes