CAMT-Automated Metalworking Solution

Experts CNC Press Brake Genius 4-6 Axis

CAMT

Experts CNC Press Brake Genius 4-6 Axis

Advanced CNC Press Brake Machine For Metalwoking Industry Solution

Preferential Automation: Smarter Bending Work For Requiremnts Automated Application

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Automation with Z1/Z2 Axis Adjustment

Superior Precision and Quality Control

Energy Efficiency and Eco-Friendliness

Flexibility for Complex Workpieces

Popular Configuration

- Taiwan TECHMATION SCS900 especially for 6+1 Axis

- CHTR Rear BGA 600MM with 300MM/S & X, R-Axis, Z1/Z2-Axis as Standard

- CAMT Itergral Advanced Hybrid Servo System

- 4 V Double CNC die series &835mm punches

- High Precision & Multi Point Mechanical Crowning

- Imported Italy GIVI Maganetic Misure

- Italy DSP Laser Protection-TOP

- Germany BOSCH-REXROTH Proportional Valve

- Full ESTUN Servo Motor/Drive

- Graphite Self-lubricating Copper Plate

- Safety France Schneider Electric System Components

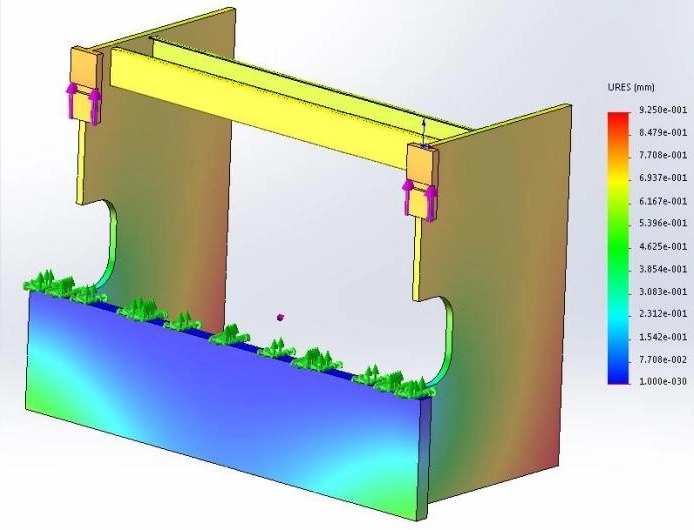

FEA & Stress Analysis of Press Brake

Stress Analysis & Finite Element Analysis

CAMT FEA plays a pivotal role by optimizing structures through stress distribution analysis to identify and reinforce high-stress areas, enhancing strength while minimizing material waste; verifying performance by predicting deformation under extreme loads (e.g., 600 tons) to ensure precision and stability for Y1/Y2 synchronization; assessing safety by evaluating stress concentration to mitigate fatigue or fracture risks for long-term reliability; and conducting dynamic analysis to simulate transient loads and vibrations in complex scenarios like tandem bending or high-speed operations, optimizing servo motor response and overall machine stability.

Taiwan TECHMATION Bending Automation SCS900

Especially for 6+1 Axis with 2D Graphic Programming & 3D Display Fuction

DELEM CNC Control System

DELEM DA66T Touch 2D Graphical Control

- 17" high resolution colour TFT

- 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- Profile-T2D offline software

- Sensor bending & correction interface

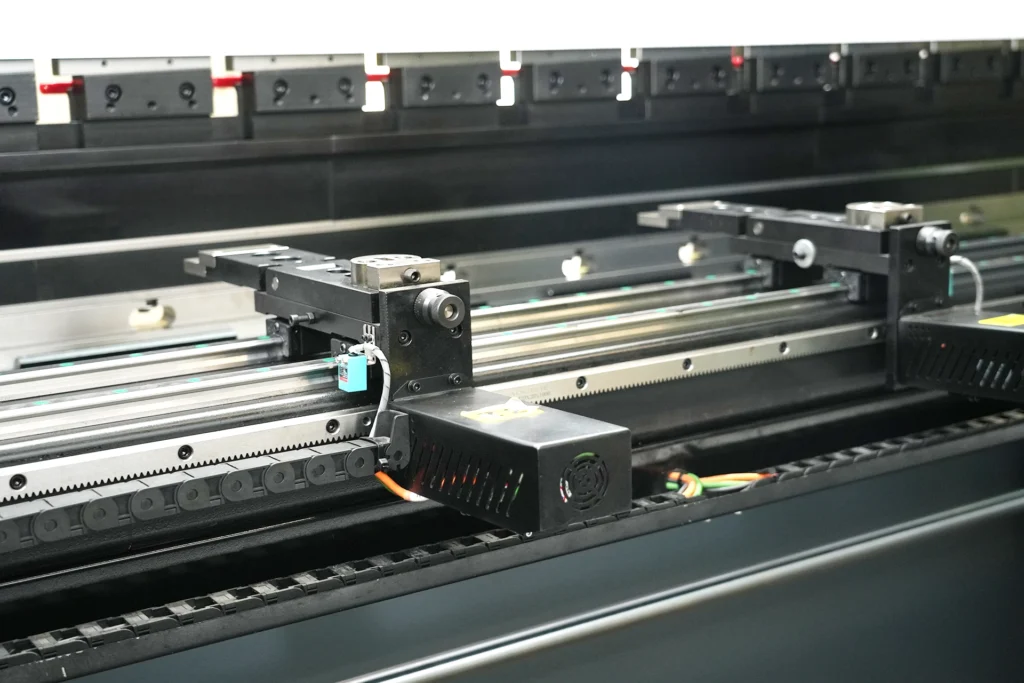

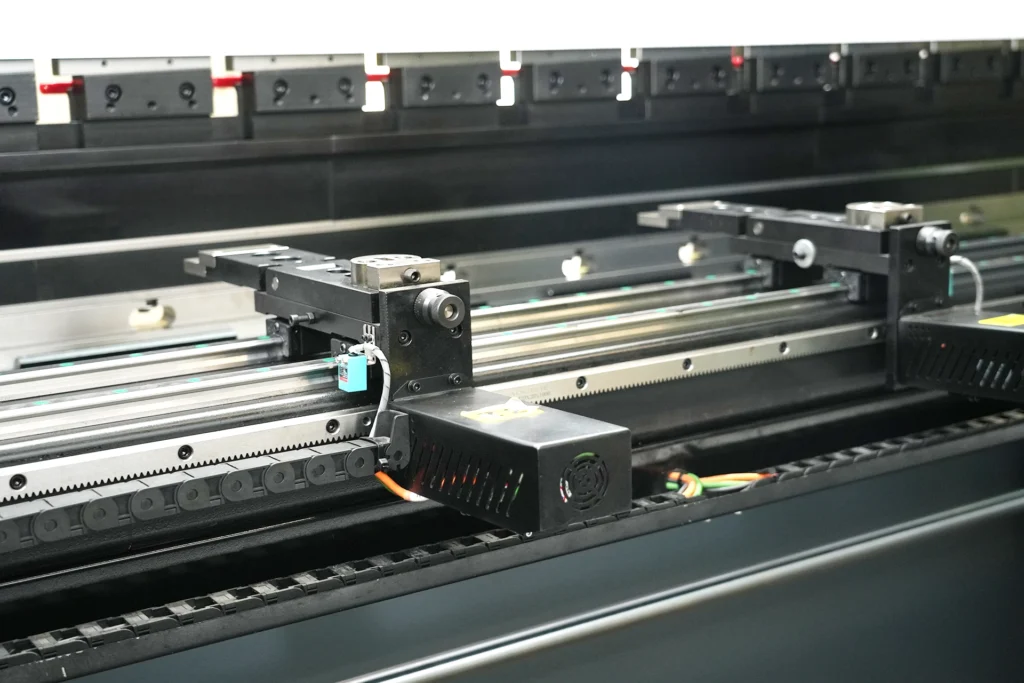

Automation CHTR Rear BackGauge

CAMT Intelligent 6 Axes CNC backgauge system

- Achieves ±0.03 mm mechanical accuracy with ball screws, linear guides, and stable racks, ensuring precise positioning and stability during bending.

- Z1-Z2 axes operate at 600 mm/s and the X-axis at 300 mm/s, boosting productivity for high-intensity tasks.

- Features fingers with double-stop and micrometric adjustment, allowing precise modifications for complex bending requirements.

- Supports 6+1 axes (X, R, Z1, Z2, etc.), offering enhanced operational flexibility and a wider processing range for diverse workpieces.

- Built with high-quality transmission components, ensuring long-term reliability and reduced maintenance costs.

- Ideal choice for modern press brake operations.

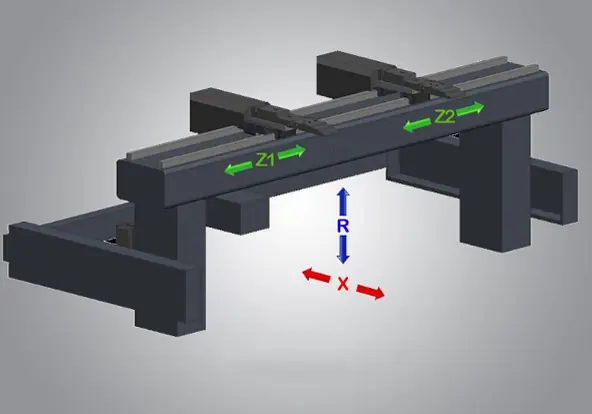

BackGauge System OverView

Designed Automated Metalworking, featuring control over X, R, Z1, and Z2 axes

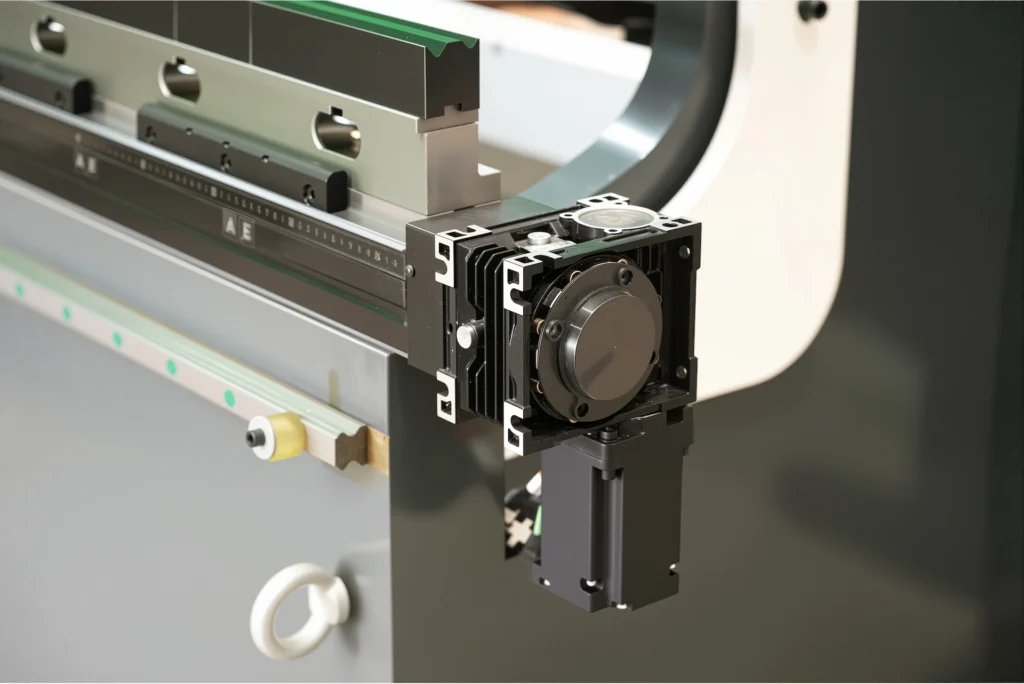

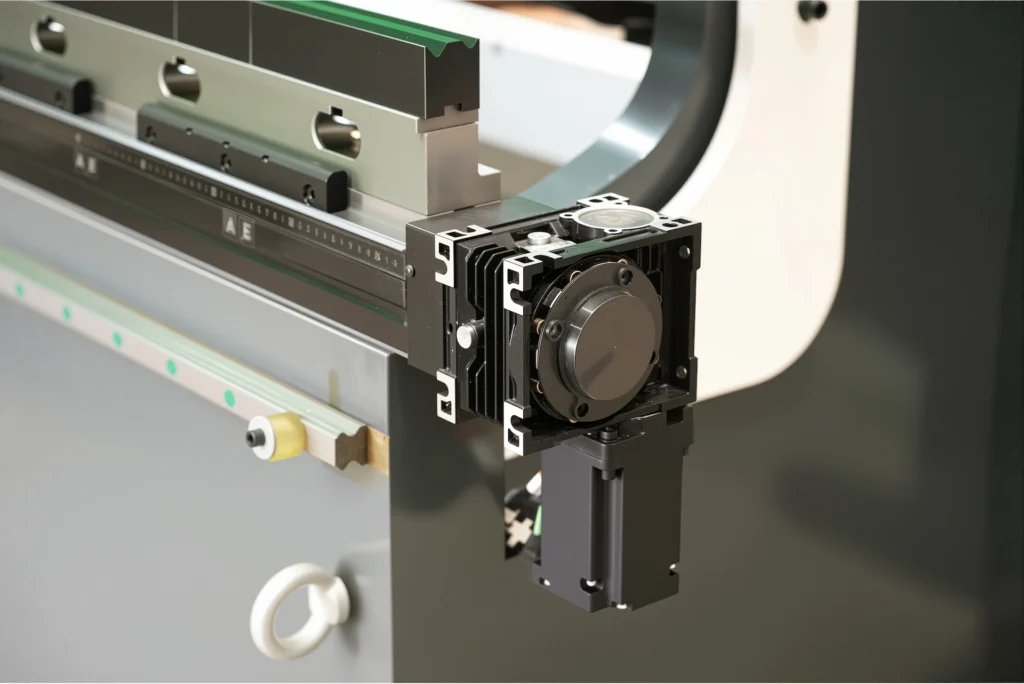

DSP Laser Safety Protection - Optional

CAMT® CNC press brake optional DSP thateliminating risks caused by the rapid movement of the machine’s slide. It creates a block-shaped protective zone.The protective zone is fixed below the tool tip and moves synchronously with the mold, ensuring that any object below the mold during high-speed descent enters the DSP-generated protective zone before contacting the tool tip.

Advantages:

- Class 1M block laser emitter

- Safety rating up to CAT.4 and SIL3

- System response time of 5ms

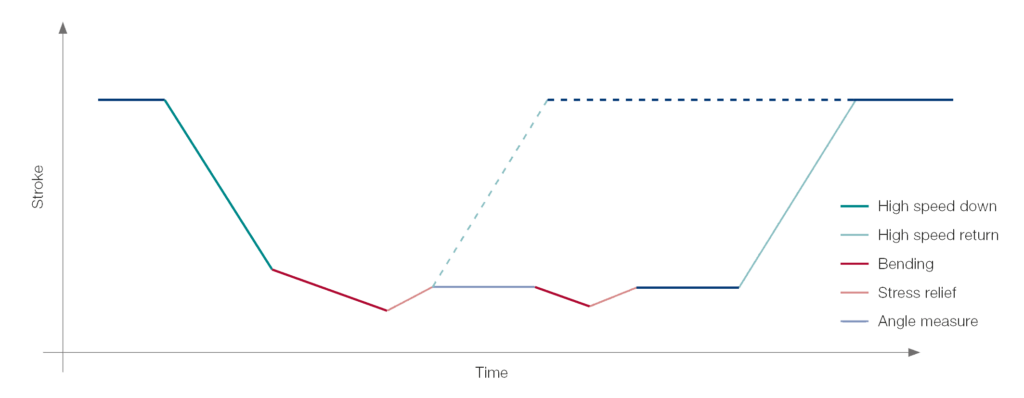

Mechanic Compensation

Precise Effectiveness & Muti-Point Crowning of Press Brake Machine

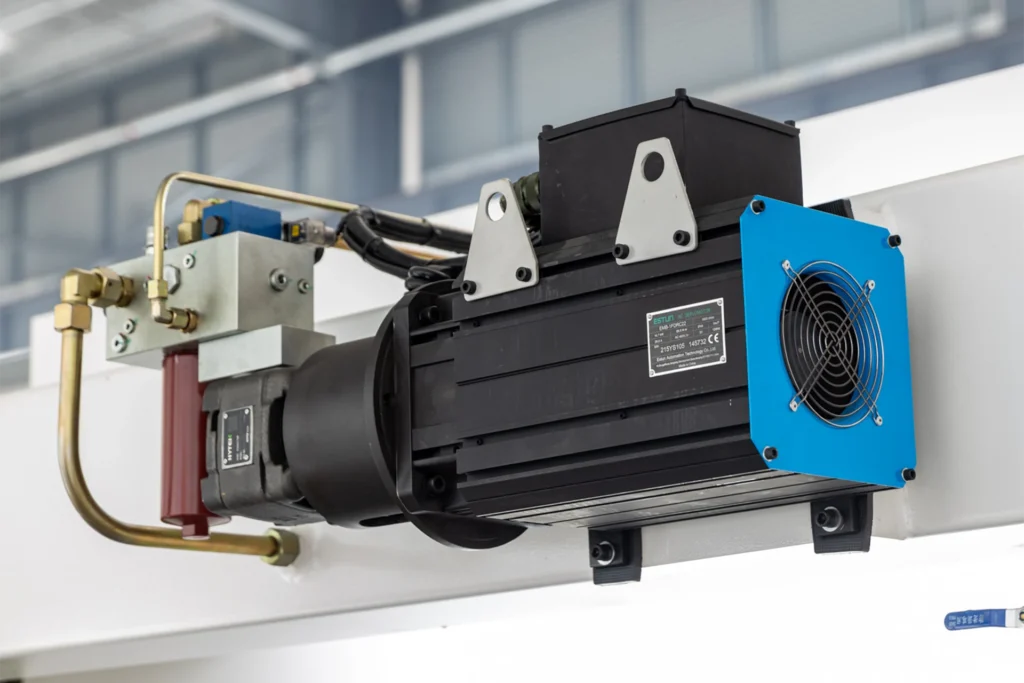

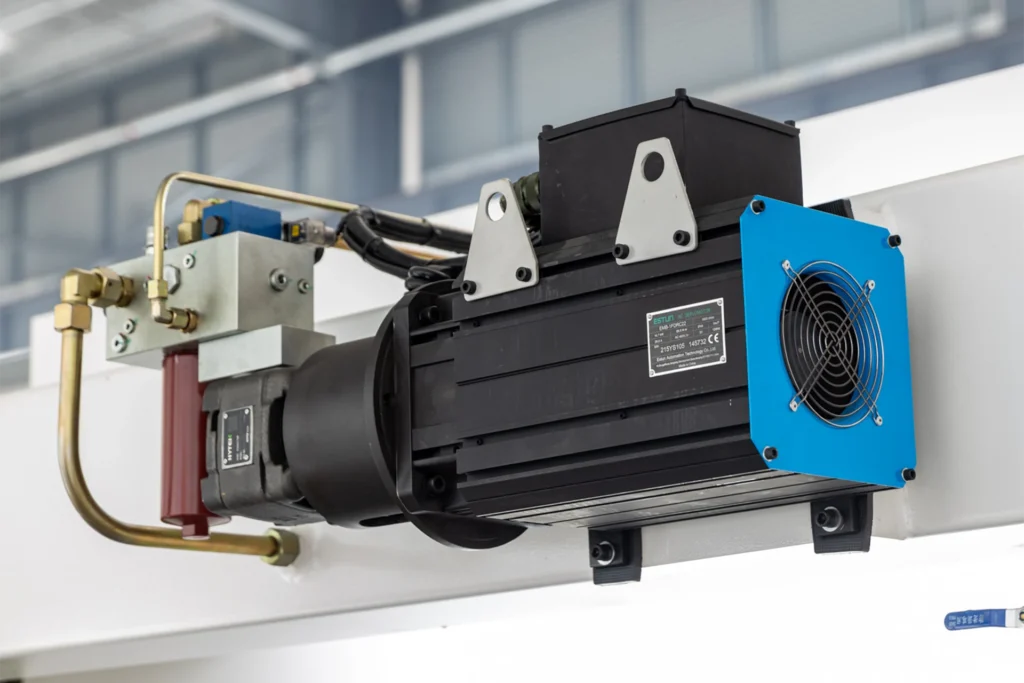

Fully ESTUN FULL SERVO/DRIVE System for Hydraulic Press Brake

Advantage:

- Precise Motion Control

- Dynamic Response

- Energy Management

- High Precision and Stability

- Fast Response

- Energy Efficiency &Easy Integration

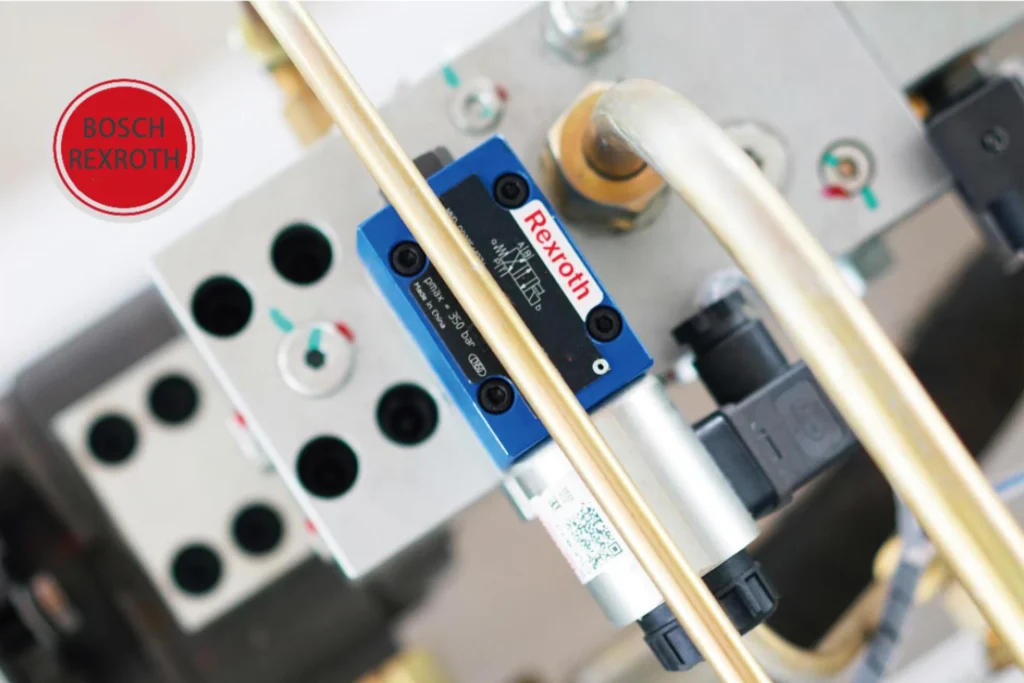

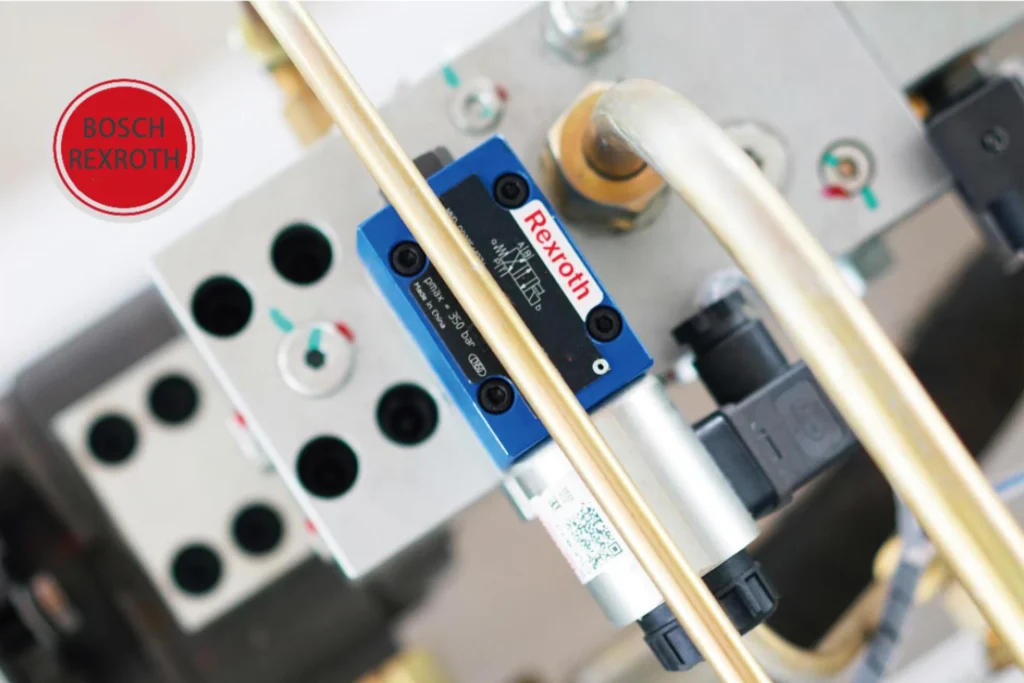

Germany BOSCH-REXROTH Hydraulic System

CAMT Party with Top-Tier Closed- Loop Control Technology

Advantage:

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.

Bending Offline Programming Software

The Core Solution for Maximizing Sheet Metal Processing Efficiency

The DELEM DA Series Offline Programming Software significantly enhances press brake productivity and processing capacity through intelligent technology. The integrated Profile-T3D system delivers a complete offline programming environment with 3D bending process simulation capabilities.

Key Technical Advantages of Profile-T3D:

As an indispensable intelligent tool for modern sheet metal fabrication, Profile-T3D provides three core benefits: Rapid import and automatic unfolding of 3D engineering drawings; intelligent optimization of tool configuration and bending sequences; and advanced 3D dynamic simulation to preemptively detect collision risks, ensuring safe and reliable processing.

The Next-Gen Smart Manufacturing Automation Solution

Leverages the CAMT® intelligent control hub and Industrial IoT (IIoT) platform to achieve high-efficiency connectivity between devices, systems, and the cloud, creating a truly seamless digital production environment. With multi-protocol compatibility, plug-and-play interfaces, and cross-platform collaboration, it significantly enhances programming efficiency, data acquisition completeness, and remote response speed. Featuring standardized connectivity, secure data transmission, and flexible scalability, it has already helped hundreds of enterprises reduce integration costs and accelerate smart manufacturing transformation. Whether for CAD/CAM integration, real-time monitoring, or cloud collaboration, this solution provides reliable technological support to modern factories, making automated production smarter and more efficient.

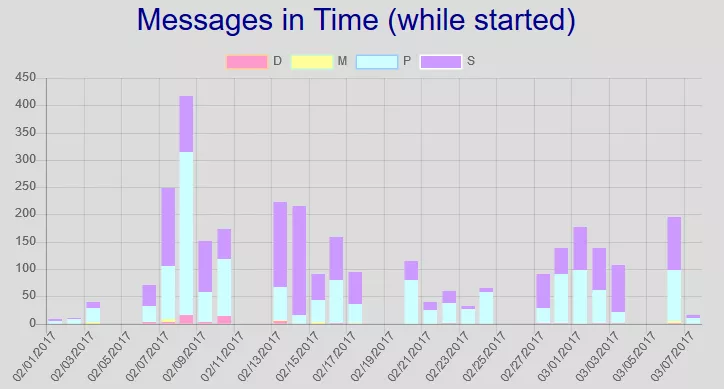

Runtime Message Monitoring

This bar chart displays statistics of various message types triggered during DA-Control operation. Only messages that were active during system runtime are recorded, including the following categories:

- D - Delem system application messages

- M - DM module messages

- P - Safety PLC generated messages

- S - Sequencer messages

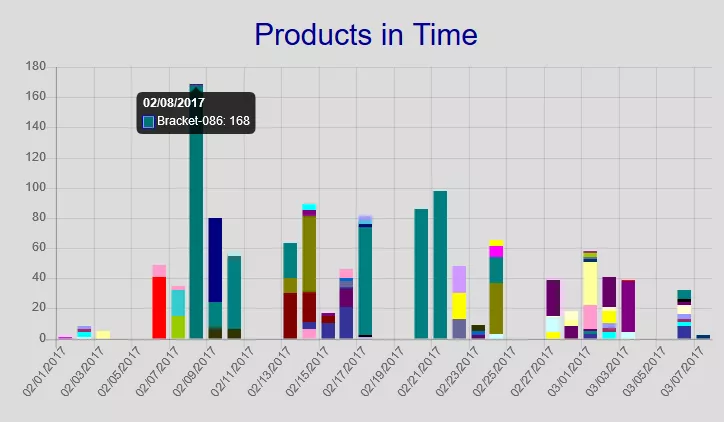

Product Production Timeline

This block presents daily production quantities for each product via bar charts. Hovering over any bar will display the product ID and specific production quantity for that date.