CAMT

HMG Series Gantry V Grooving Machine

CAMT

Gantry V Grooving Machine

HMG Serious High Speed V Cut with Stability

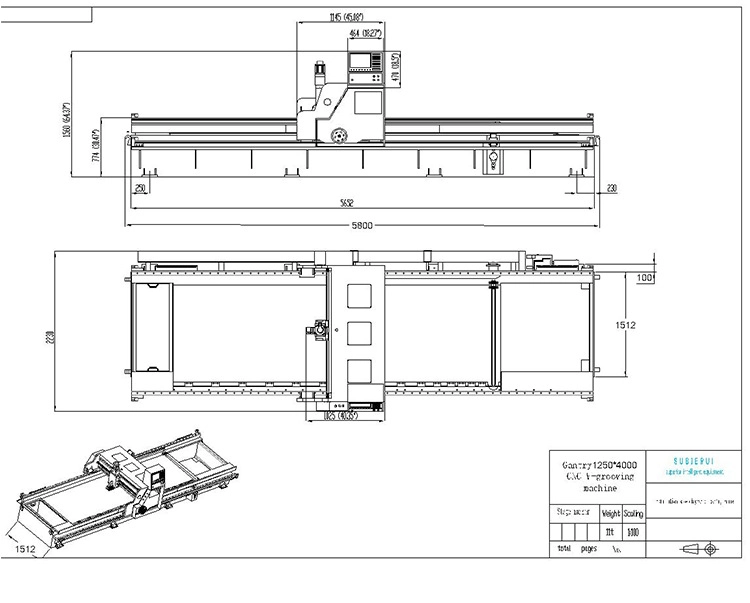

CAMT adopts a frame structure design with high-strength bolt connections, ensuring excellent overall rigidity and minimal deformation. The beam is fixed, and the workpiece is fed through a feeding mechanism, with the workbench anvil adjustable to maintain a surface flatness within ±0.02mm. The left and right movement of the tool post utilizes synchronous belt transmission, providing stable and efficient cutting with a flat and smooth cutting surface. Additionally, a floor-standing numerical control rear feeding device is employed, offering high positioning accuracy, stable transmission, and a wide processing range.

CAMT primary transmission of the motor adopts V-belt transmission. Due to the tension of the V-belt, the impact force during sudden stops and rapid reversals is reduced. This ensures the stable operation of the equipment and extends its service life.

CAMT V Grooving Machine

Incorporates the Following Attributes and Capabilities

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Precision Shaping

Super Fast

Smart Felexibility

Durable Lifetime

HMG Grooving Machine Frame

Robust and Precision-Engineered

HMG grooving machine features a robust frame structure designed for exceptional durability and precision. Both the base and beam are constructed with a high-strength frame, utilizing 60mm low-alloy high-strength structural steel for the work surface and Q345 steel plates for the frame, ensuring outstanding overall rigidity and long-term reliability. To eliminate welding stress and minimize deformation, the bed undergoes natural gas tempering, while a sandblasting process guarantees a superior paint finish. Additionally, the working table offers a self-repairing function, allowing users to plane the tabletop as needed to maintain machining accuracy, providing flexibility and consistent performance tailored to specific requirements.

Intuitive and Safe

Control System of Slotting Machine

- Simplified Programming: Operators can input processing programs via the keyboard, streamlining setup and enabling quick operation tailored to specific tasks.

- Adjustable Processing Speed: A knob allows easy adjustment of processing speed based on operator preferences or material variations, ensuring operational flexibility.

- Real-Time Monitoring: The display screen provides clear visibility of the processing status, allowing operators to track progress and make informed adjustments.

- Enhanced Safety: Integrated sensors ensure operator safety by detecting potential hazards during operation.

- Abnormality Alerts: In case of equipment issues, the display screen shows alarm messages, facilitating prompt troubleshooting and maintenance.

Precision Cutting and Versatility

Alloy Blade of V Grooving Machine

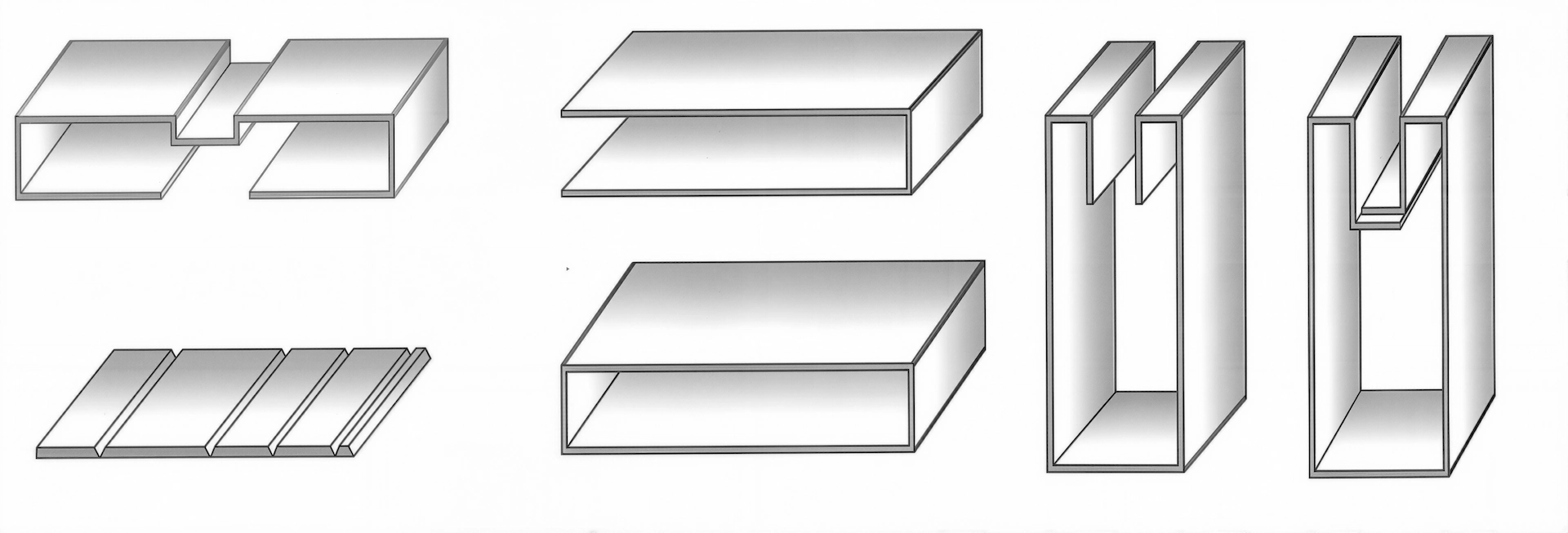

The blade system of the HMG grooving machine is designed for precise and efficient “V” groove processing. Equipped with four knives, it evenly distributes the cutting load, minimizing workpiece deformation. An optional micro-cooling system extends tool longevity and reduces production costs. CAMT slotting machine further enhances versatility by supporting longitudinal and transverse processing, with a specialized “front and back” processing function for plates. This advanced blade system ensures high-quality cuts, durability, and operational flexibility.

Fast and Stability

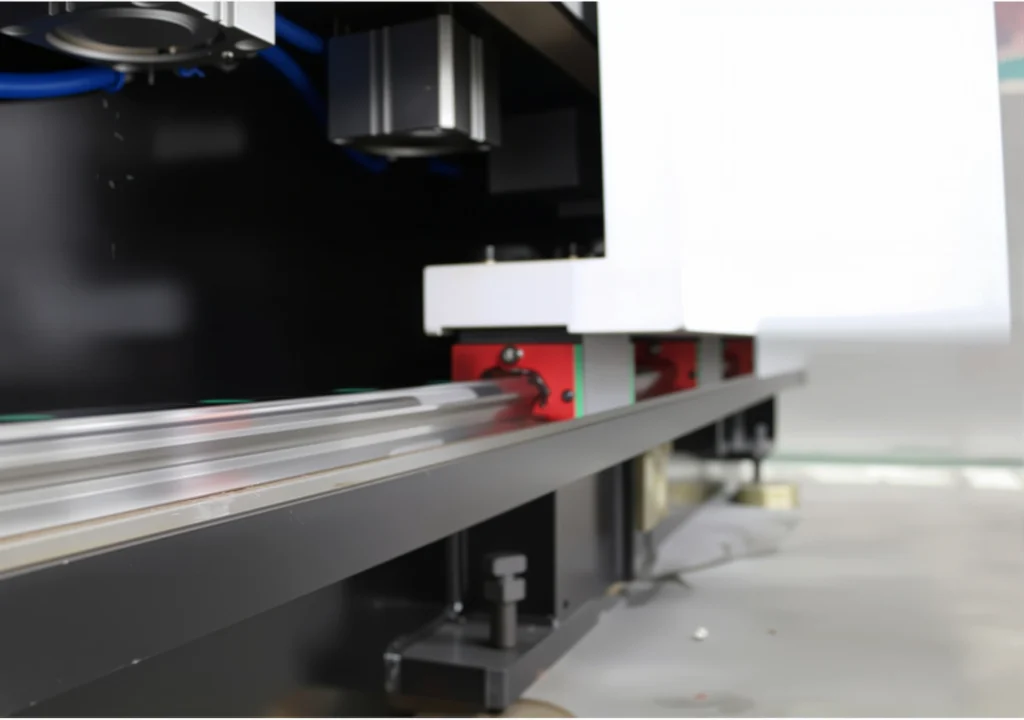

Guide and Drive System About Grooving Machine

- Precision copper gear and helical rack drive, supplemented by Taiwan HIWIN heavy-duty linear guide, the moving speed can be adjusted by frequency conversion, and the cutting process is stable and efficient.

- CAMT tool holder transfer device of HMG grooving machine uses SFSR silent ball screw and QH silent guide rail to ensure high accuracy.

Secure and Energy-Efficient

Clamping System of V Grooving Machine

HMG grooving machine features a robust hydraulic clamping system designed to securely fix workpieces, ensuring fast slotting speeds and reliable clamping force. Equipped with accumulator compensation and an overflow valve, the hydraulic system optimizes performance while maintaining safety. The intermittent operation of the motor minimizes energy consumption, enhancing efficiency. This advanced clamping system provides strong, stable, and energy-saving performance, making it ideal for high-precision grooving applications.

Technical Parameter

| Model | HMG-1250/1500×2500/3000/4000/5000/6000 |

|---|---|

| Machining Capacity | Material - STS304 & Q345 |

| Length - 2500/3000/4000/5000/6000mm | |

| Width - 1250/1500mm | |

| Thickness - 0.6mm-4mm(Sheet Flatness < 3mm) | |

| Minimum edge - 8mm | |

| CNC Specifics | Control Type - 4 Axis CNC Control (X.Y1, Y2, Z) |

| Display - 15 inch Touch Screen | |

| Memory Capacity - 99 group, 9999 Line / Group (99 line circle available) | |

| Working System - Linear Guide/ Ball Screw/Gear Rack | |

| Speed | Forward-Cutting(X-axis) - 0-90m/min |

| Backward(X-axis) - 0-90m/min | |

| Y1 axis and Y2 axis - 20m/min | |

| Z axis, Z-Axis UP-Down - 20m/min | |

| Machining Precision | Y1 axis, Y1 Precision - ± 0.01mm |

| Y1 axis, Max. Y1 Stroke - 1250mm | |

| Z axis, Y1 Precision - ± 0.01mm | |

| Z axis, max Z Stroke - 50mm | |

| Driving Mode | X-Axis - 4.5KW Servo Motor, Taiwan |

| Z-Axis - 1KW Servo Motor, Taiwan | |

| Y1 axis, Y2 axis; Y1 & Y2 - 1KW Servo Motor, Taiwan | |

| Clamping Device | Hydraulic |

| Table Flatness | ±0.02mm/M |

| Main Power | 380V/50Hz/3Phase |

Advantage:

- Frame-designed beam with heat-treated body ensures durability and no deformation.

- Gear-rack driven beam with frequency-adjustable speed for smooth, efficient cutting.

- Four-axis CNC (X, Y1, Y2, Z) with high positioning accuracy and wide processing range.

- Hydraulic side and end clamping with adjustable force for secure workpiece fixing.

- V-belt drive reduces impact during sudden stops, enhancing stability and lifespan.

- Accumulator compensation and intermittent motor operation save energy and control oil temperature.

- Restores uneven or worn worktable to like-new condition after prolonged use.