Max. Running Speed 120M/MIN

Heavy Duty Super Press Brake

Max. Running Speed 120M/MIN

Heavy Duty Super Press Brake

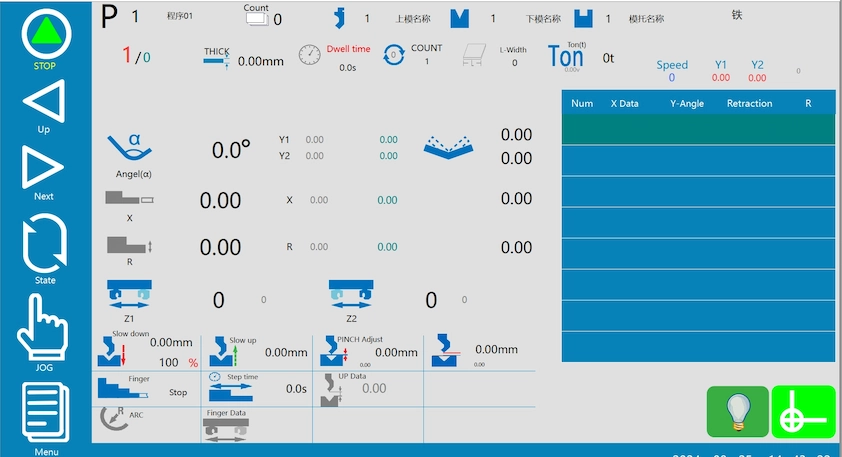

21.6-inch color high-definition touch screen with friendly human-machine interface

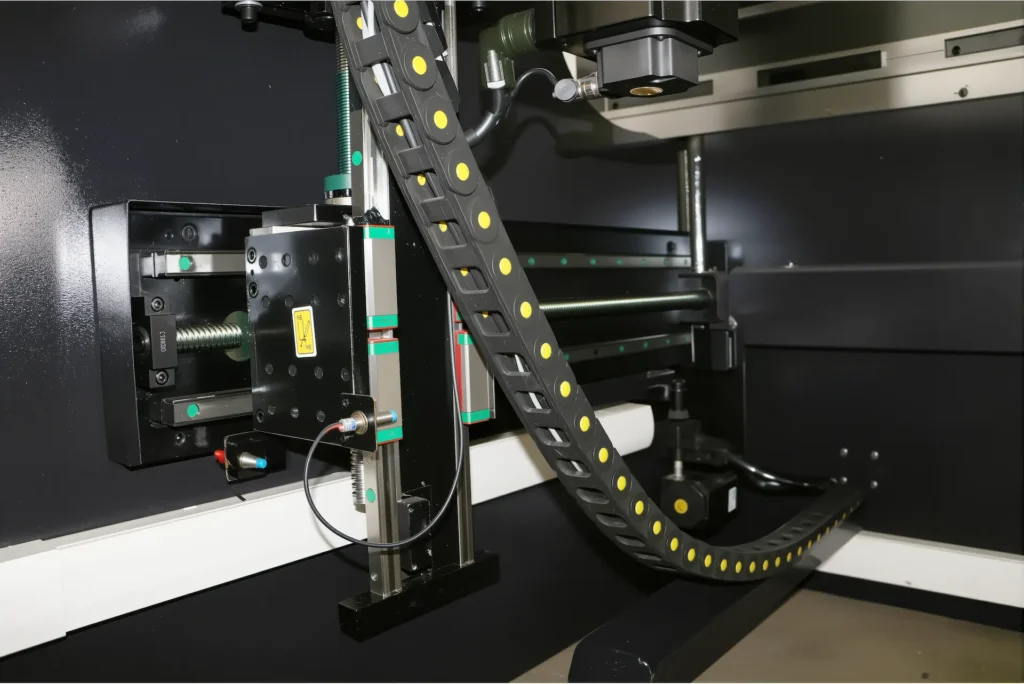

CHTR Rear BGA 600MM with 300MM/S.

4 V Double CNC die series &835mm punches.

Imported Italy GIVI Maganetic Misure

- All-In-One Effective Servo Motor

- Graphite Self-lubricating Copper Plate

- Safety France Schneider Electric System Components

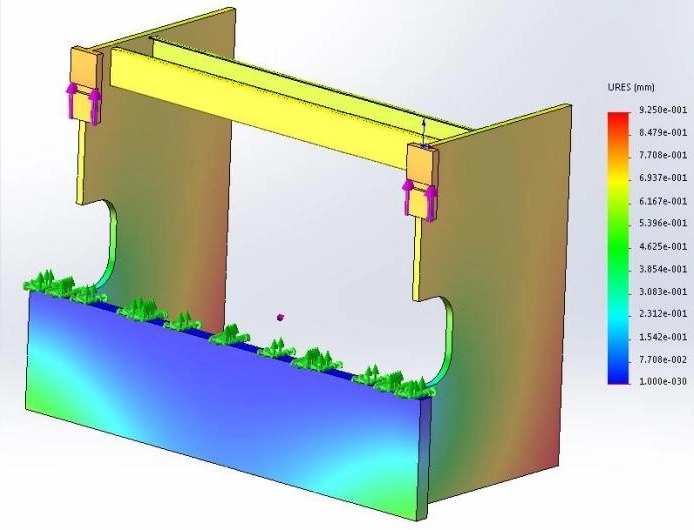

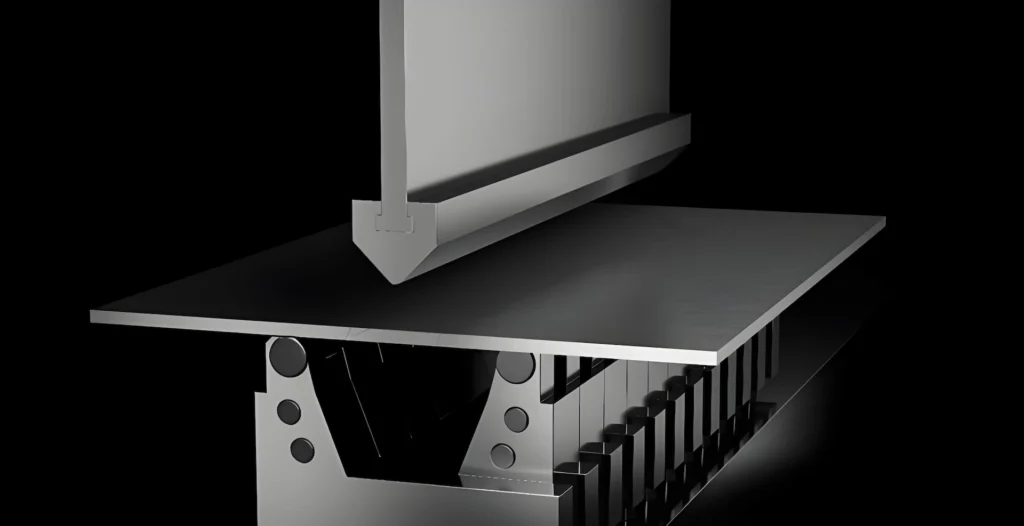

- FEA & Stress Analysis of Press Brake

- Stress Analysis & Finite Element Analysis

- CAMT FEA plays a pivotal role by optimizing structures through stress distribution analysis to identify and reinforce high-stress areas, enhancing strength while minimizing material waste; verifying performance by predicting deformation under extreme loads (e.g., 600 tons) to ensure precision and stability for Y1/Y2 synchronization; assessing safety by evaluating stress concentration to mitigate fatigue or fracture risks for long-term reliability; and conducting dynamic analysis to simulate transient loads and vibrations in complex scenarios like tandem bending or high-speed operations, optimizing servo motor response and overall machine stability.

- DELEM DA66T Touch 2D Graphical Control

- 17" high resolution colour TFT

- 2D graphical touch screen programming mode

3D visualisation in simulation and production

Full Windows application suite

Delem Modusys compatibility (module scalability and adaptivity).

DataM or Iris-Plus angle messurement management(options).

Sensor bending & correction interface

- Heavy Duty Structure Bending Machine

- High Strength & Stability Large Press Brake

- designed for processing large workpieces, accommodating ultra-long , wide, or heavy plates, and is widely used in manufacturing for ships, bridges, steel structures, wind turbine towers, and pressure vessels. It supports complex shape processing through CNC programming, enabling multi-angle and multi-stage bending to meet intricate geometric requirements. High-precision production is ensured by synchronous control and backgauge systems, maintaining consistent bending angles and dimensions for industrial components with stringent accuracy demands. The machine facilitates batch production with multi-program storage making it suitable for mass production or single-piece customization. Its versatility spans multiple industries, including steel structures, rail transportation, aerospace, and energy equipment, processing components such as lamp poles, carriage panels, and building curtain walls.

- Optional Safety Arrangement - Light Curtain

- Electro-hydraulic servo system and grating ruler feedback ensure slider synchronization accuracy within ±0.01 mm

- High backgauge positioning accuracy (±0.05 mm), ideal for precision parts production

- Automatically calculates bending force and stroke, reducing setup time and supporting quick mold changes and programming

- Supports various mold configurations to meet different thickness and material processing needs

Tandem machine management(option, can up to 4 machines)

ESA S650W 2D Graphical CNC System

- No limit in both performances and flexibility.

- "The powerful built-in Pc allows having on the machine a real 3D cad cam (metallix, radan, esa)

- Finger-tip work piece design.

- Direct import of tools shapes (.dxf files) and management of tool library.

- Tool and die holders management.

- Angle measurement and correction with all existing devices is available.

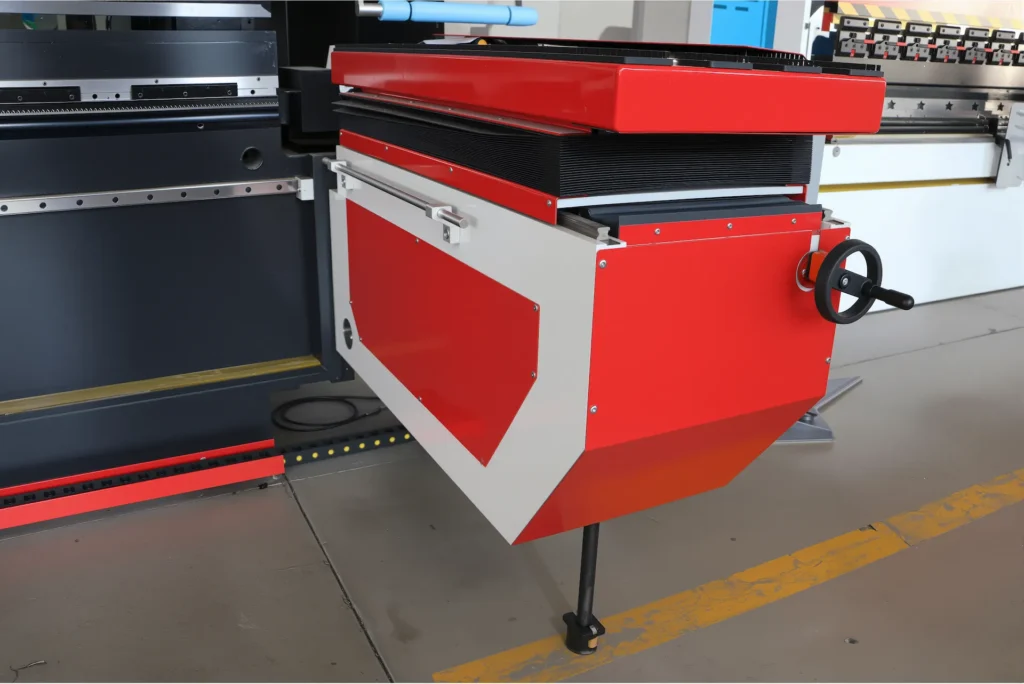

Adjustable Big V Die

Used for various complex metal processing tasks, overcoming challenges in traditional bending applications

Bending accuracy can reach 30 degrees, depending on the synchronization capability of the machine.

Compared to traditional models, reduces bending pressure by 10%

- Overcomes issues of material deformation, reducing model replacement time by 30% or more

- Compared to traditional models, consume less energy in operation, making them more user-friendly

- Can be conveniently transported and added to workpieces (models), supporting customer-added integrated operations

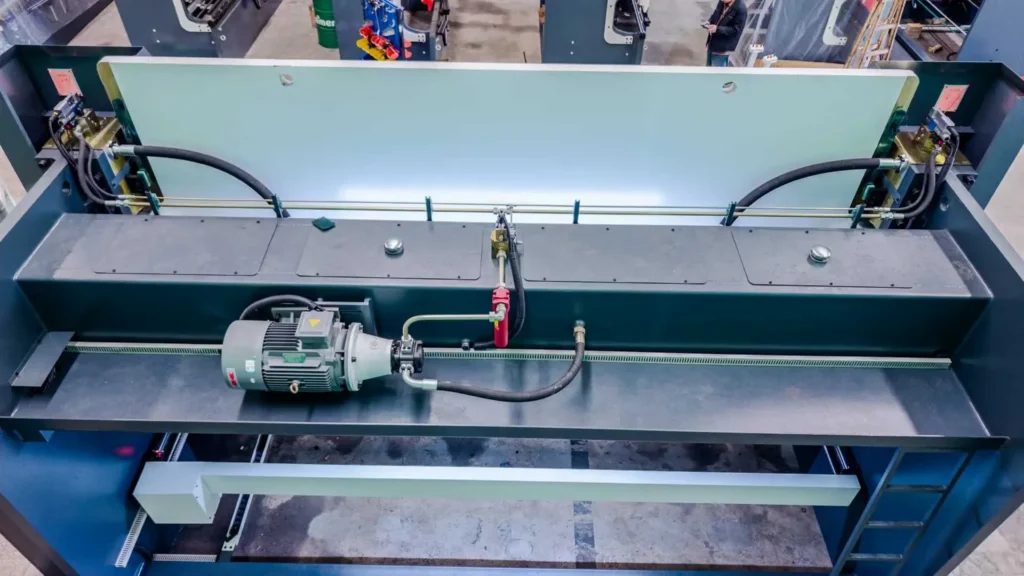

- CAMT Itergral Hydraulic System

- Advanced Hybrid Servo ECO Technology

Ensures machine stability and rigidity with strict inspections and finite element analysis.

Delivers real-time feedback and micron-level precision.

Boosts efficiency with 20% faster response than hydraulic systems.

Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.

- breadcrumbs

- Customizable to suit various workshop environments and meet the needs of different bending machines

- Stable conditions minimize risks of equipment overheating or operational errors

Adjustable Big V Die

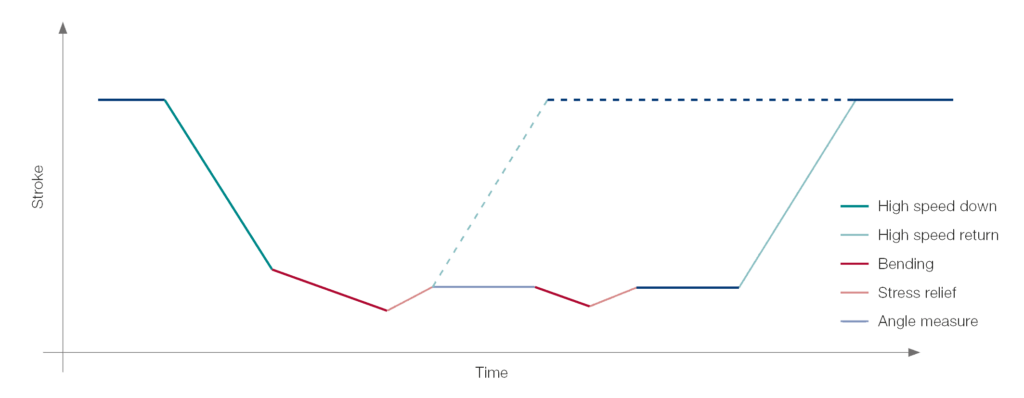

Soft stop mode

- Used for various complex metal processing tasks, overcoming challenges in traditional bending applications

- Bending accuracy can reach 30 degrees, depending on the synchronization capability of the machine

- Compared to traditional models, reduces bending pressure by 10%

- Overcomes issues of material deformation, reducing model replacement time by 30% or more

- Compared to traditional models, consume less energy in operation, making them more user-friendly

- Can be conveniently transported and added to workpieces (models), supporting customer-added integrated operations

CAMT Itergral Hydraulic System

Advanced Hybrid Servo ECO Technology

CAMT optimize energy efficiency while delivering superior performance. By integrating a hybrid servo-electric and hydraulic system, this technology significantly reduces energy consumption, ensuring eco-friendly operations without compromising power. The seamless integration of components enhances system efficiency, providing precise positioning at every stage of the bending process. This innovative solution not only lowers operational costs but also supports sustainable manufacturing with its energy-saving design and reliable, high-precision performance.

Soft stop mode

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.