Max. Running Speed 120M/MIN

HMV Series Vertical V Grooving Machine

Max. Running Speed 120M/MIN

CAMT V Grooving Machine

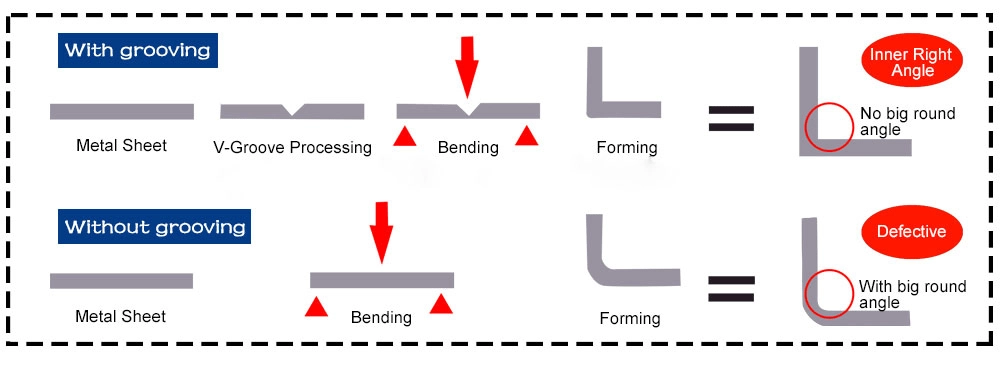

Precision Shaping

Super Fast.

Smart Felexibility.

Precision Cutting and Versatility

CAMT adopts rack and pinion transmission structure, standard manual clamping chuck, push-type pipe cutting method, can be used for general sheet metal cutting and common square tube, round tube, rectangular tube cutting.

55X55

55X55

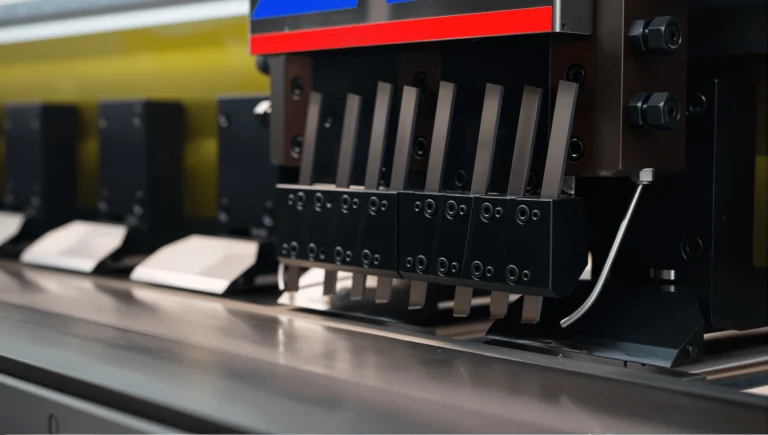

Clamping System of V Grooving Machine

CAMT HMV grooving machine boasts a powerful hydraulic clamping system that firmly secures workpieces, delivering rapid slotting speeds and consistent clamping strength. Integrated with an accumulator for compensation and an overflow valve, the hydraulic setup ensures optimal performance and safety. The motor’s intermittent operation reduces energy use, boosting efficiency. This sophisticated clamping mechanism offers robust, reliable, and energy-efficient performance, perfectly suited for high-precision grooving tasks.

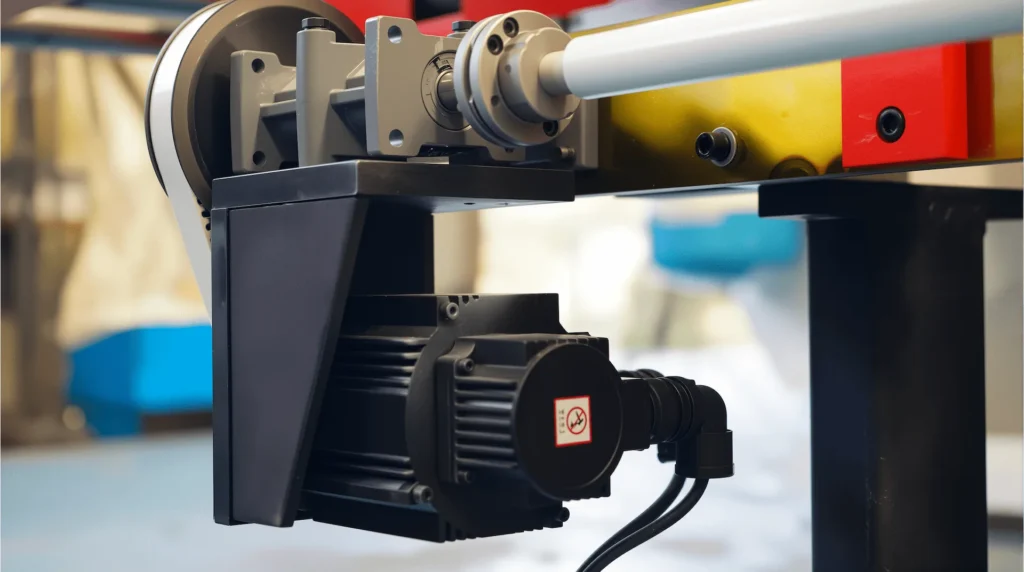

High-Precision Control

Servo Motor & Drive System of Slotting Machine

Servo drives offer rapid response times and excellent acceleration/deceleration performance, enabling quick starts, stops, and speed changes to enhance grooving efficiency, especially for complex contours.

Servo motors consume power only under load, reducing energy consumption by 30%~50% compared to traditional stepper motors or hydraulic systems, leading to long-term cost savings.

Servo systems provide strong overload resistance and stable torque at low speeds, preventing vibration or step loss during grooving, ensuring consistent performance in continuous operation.

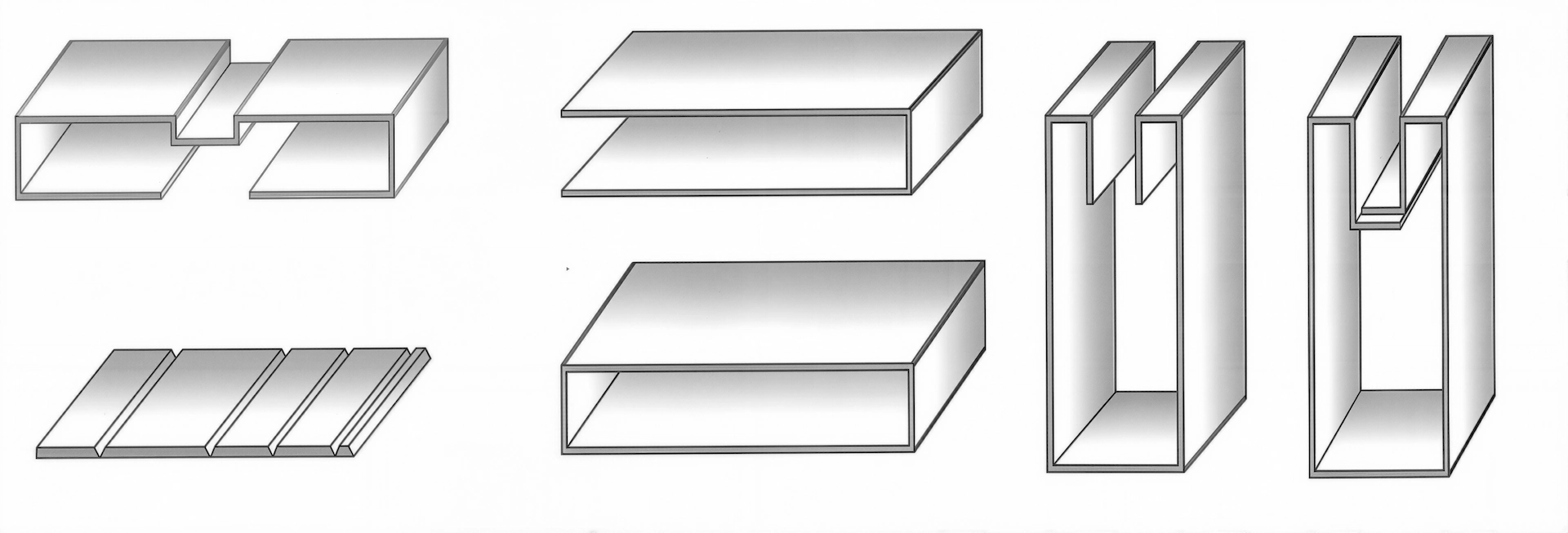

Convenient Saving Manpower

Feeding Device for V Grooving Machine

CAMT feeding device of a vertical CNC slotting machine is designed to automatically and precisely transport and position workpieces, ensuring stable movement along a preset path and speed during processing. Utilizing components such as servo motors, guide rails, and clamping mechanisms, it accurately controls the feed rate and position of the workpiece, enhancing machining precision and efficiency while reducing manual operation, labor intensity, and errors. It is suitable for slotting processes on materials like metal sheets.

Technical Parameter

Model Name/Number

- Max. material width (mm).

- Max. material length (mm).

- Max. material thickness (stainless steel flatness.

<3mm)

Min. material thickness (mm)

Min. distance from edge to V-groove (mm).

Cutting speed

| Tool holder left-right movement resolution (mm) | 1250/3200 | 1600/3200 | 1250/4200 | 1600/4200 | 1600/5200 | 1600/6200 |

|---|---|---|---|---|---|---|

| Positioning accuracy (mm) | 1250 | 1600 | 1250 | 1600 | 1600 | 1600 |

| ±0.01 | 3200 | 3200 | 4200 | 4200 | 5200 | 6200 |

| Tool holder up-down movement resolution (mm) Main servo motor power (Kw) | 4 | 4 | 4 | 4 | 4 | 4 |

| Hydraulic system working pressure (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Machine dimensions (L×W×H, mm) | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 | 8-10 |

| 4600×2700×2100 | 55 | 55 | 55 | 55 | 55 | 55 |

| 4600×3000×2100 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| 5600×2700×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 |

| Imported system ensures sensitivity and durability. | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| 5600×2700×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 | 5600×3000×2100 |

| Main servo motor power (Kw) | 4 | 4 | 4 | 4 | 4 | 4 |

| Hydraulic system working pressure (Mpa) | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Machine dimensions (L×W×H, mm) | 4600×2700×2100 | 4600×3000×2100 | 5600×2700×2100 | 5600×3000×2100 | 6600×3000×2100 | 7600×3000×2100 |

Soft stop mode

- Box-type design, CNC-milled, and tempered for rigidity, precision, and long life.

- simple operation and automatic calculations.

- 130 m/min slotting and ±0.01 mm accuracy.

- Imported system ensures sensitivity and durability.

- Independent clamps and precise rear stop (±0.02 mm linear accuracy).

- Imported parts for reliability.

- Ensures sensitivity and durability.