Working Principle of Laser Cutting Machines and Their Differences from Plasma Cutting Machines

Cutting Efficiency, Low, suitable for thin and medium-thick plates. Low, suitable for cutting thin metal sheets. High efficiency., Applications.

Automotive, aerospace, shipbuilding, metal processing, 3D printing.

Mechanical manufacturing, metal processing.

Precision machining in industrial production.

Suitability

Oxygen cutting of low-carbon steel: mainly for thin and medium-thick metal plates; widely used in industrial oxygen cutting.

Widely used in metal processing for oxygen cutting.

Widely used in industrial oxygen cutting.

Notes

The Future of Laser Cutting.

Laser cutting’s precision, adaptability, and efficiency ensure its continued dominance in industrial applications. With advancements in fiber laser cutters and CNC cutting machines, the technology is poised for even broader adoption. From automotive to aerospace, laser cutting’s ability to handle diverse materials and complex designs makes it a vital tool for modern manufacturing.

How to Properly Install a Press Brake Machine.

Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

blog.

press brake machine

press brake safety

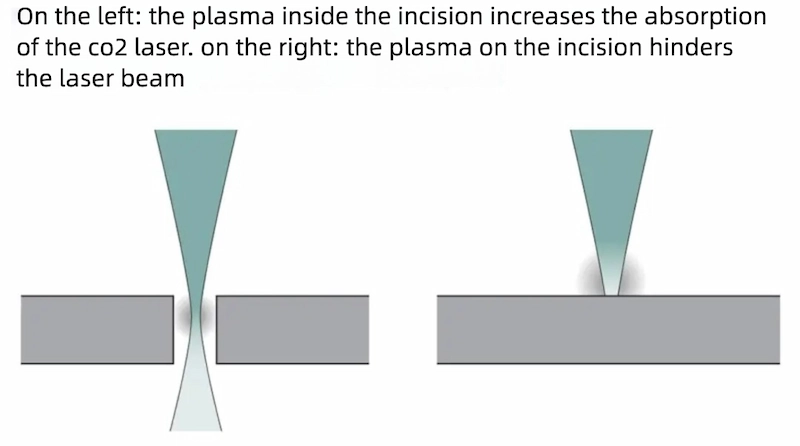

Polarization Degree: Typically around 90%, ensuring sufficient energy conversion for high-quality cuts.

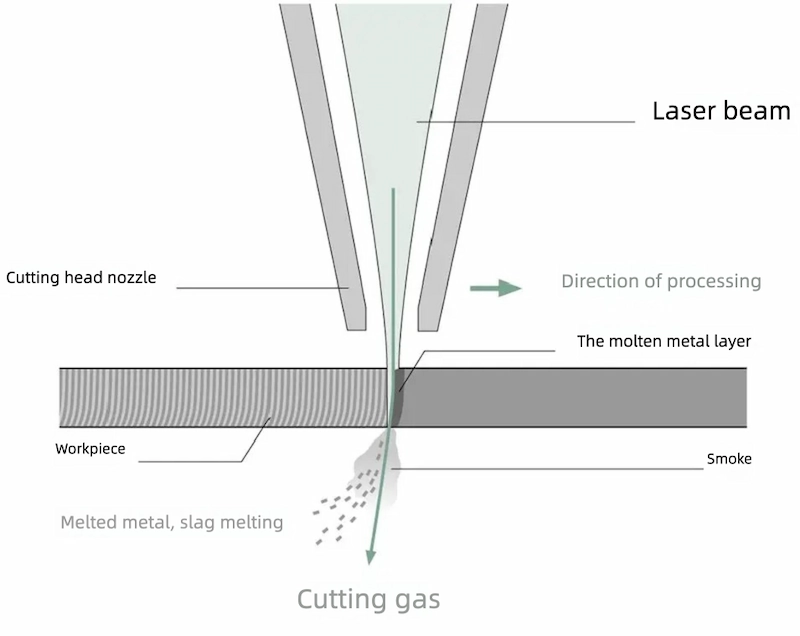

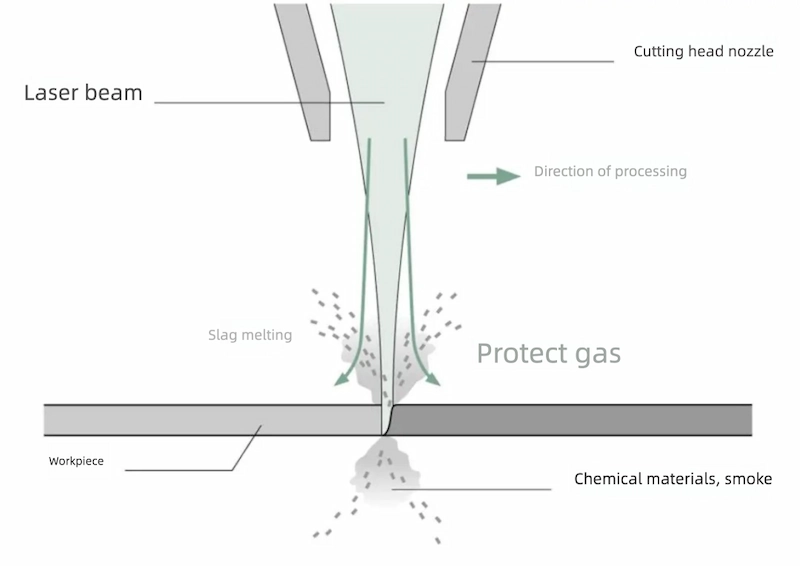

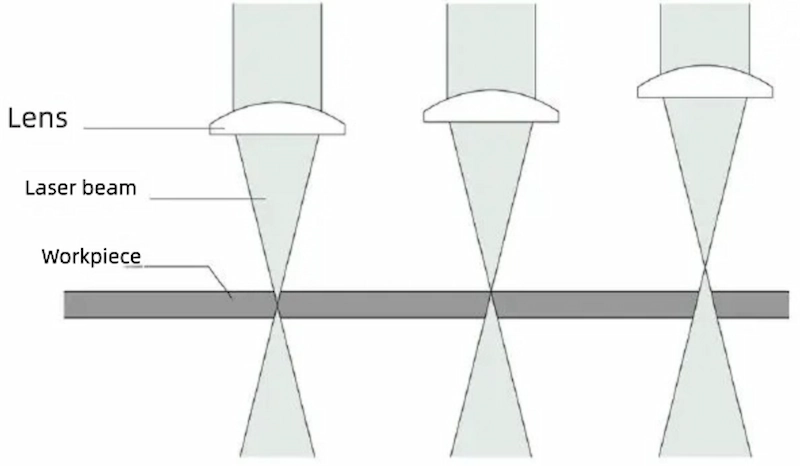

Focal Diameter: A smaller focal diameter results in narrower kerfs, adjustable via the focusing lens.

Focal Position: Determines beam diameter and power density, affecting kerf shape (e.g., inside, on, or above the workpiece surface).

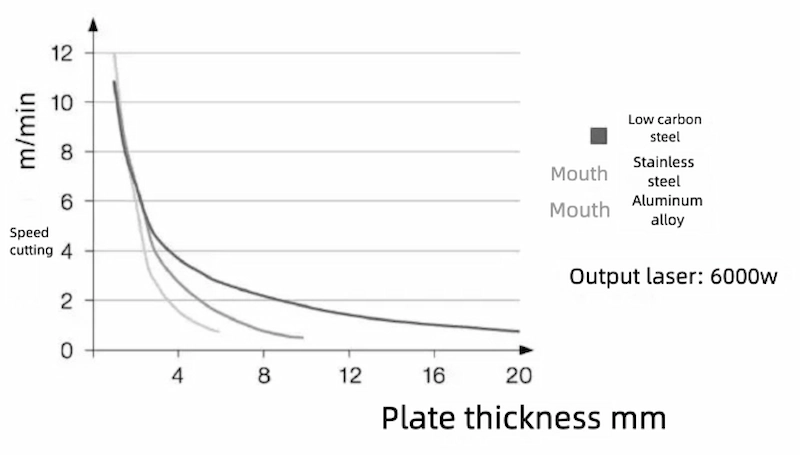

Laser Power: Must match material type and thickness to exceed the processing threshold. Higher power enables cutting thicker materials.

Image: Graph showing laser power vs. material thickness.

Operating Mode: Continuous mode suits standard contours, while pulsed mode is used for precision cuts or perforations.

Cutting Speed: Must align with laser power; too fast or slow speeds increase roughness and burrs.

Nozzle Diameter: Influences gas flow and shape; larger nozzles are used for thicker materials.

Gas Purity and Pressure: Oxygen requires 99.95% purity for flame cutting, while nitrogen needs 99.995% for fusion cutting. Thicker materials require lower oxygen pressure but higher nitrogen pressure.

Modern laser cutting systems store optimized parameters for various materials and thicknesses, enabling even novices to achieve professional results.

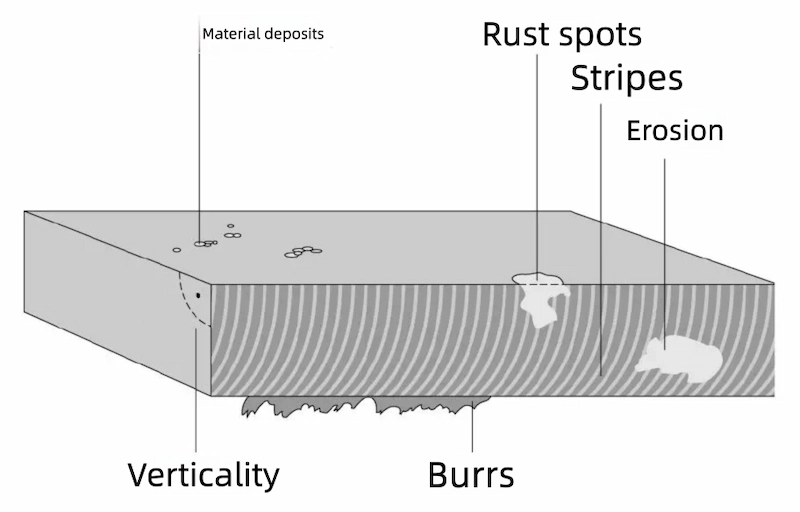

Evaluating Laser Cutting Quality

Cutting quality is assessed through visual and measurable criteria:

Visual Standards: Burr formation, depressions, and texture.

Measurable Standards: Perpendicularity, roughness, and kerf width, requiring specialized tools.

Additional Factors: Material deposition, corrosion, heat-affected zones, and deformation.

How Does Plasma Cutting Differ?

Plasma cutting uses a high-temperature plasma arc, created by ionizing gas (e.g., nitrogen, argon, or oxygen) with an electric arc, to melt and cut materials. Unlike laser cutting, which relies on a focused light beam, plasma cutting is less precise but excels in cutting thicker metals (up to several inches) at lower costs.

Key Differences Between Laser and Plasma Cutting

Precision and Kerf Width

Laser Cutting: Offers high precision with narrow kerfs (as small as 0.1 mm), ideal for intricate designs and thin materials.

Plasma Cutting: Produces wider kerfs (1–2 mm), less suited for detailed work but effective for thicker materials.

Material Versatility

Laser Cutting: Cuts a wide range of materials, including metals, plastics, wood, and ceramics, with minimal thermal distortion.

Plasma Cutting: Primarily used for conductive metals (e.g., steel, aluminum), less effective for non-metals.

Cutting Speed

Laser Cutting: Faster for thin materials (<10 mm) due to precise energy delivery.

Plasma Cutting: Faster for thicker materials (>10 mm) due to high heat output.

Cost and Maintenance

Laser Cutting: Higher initial investment and maintenance costs (e.g., for fiber laser cutters or CNC cutting machines).

Plasma Cutting: Lower equipment and operational costs, making it more economical for heavy-duty applications.

Edge Quality and Heat-Affected Zone (HAZ)

Laser Cutting: Produces smoother edges with minimal HAZ, reducing post-processing needs.

Plasma Cutting: Results in rougher edges and larger HAZ, often requiring additional finishing.

Category | Flame cutting | Melt cutting | Gas cutting |

Interface: Touch-screen CNC systems with 3D visualization simplify programming. | The laser beam heats the metal to its melting point, and the laser energy cuts through the metal with a high-pressure gas stream, resulting in smooth edges without burrs. | Gas (oxygen) reacts with the metal being cut (combustion), and the released energy melts and blows away the metal. | Pure thermal effect, where the gas laser beam heats the metal to melting or evaporation. |

Materials Used | CO₂ laser, solid-state laser | CO₂ laser, gas laser | Three-phase imaging light |

Application Range | Mainly used for precision cutting of metal and non-metal materials, suitable for thin and medium-thick plates. | Mainly used for cutting low-carbon steel, stainless steel, aluminum alloys, and other metal materials. | Metals, titanium alloys, nickel-based alloys, copper, etc. |

Heat Affected Zone Width | 0.1–0.5 mm | 0.1–0.5 mm | 0.01–0.04 mm |

Typical Quality Evaluation Standards | Burr formation, cut surface perpendicularity, roughness, cut edge collapse, cut width, kind perpendicularity, cut surface roughness. | Burr formation, cut surface perpendicularity, roughness, cut edge collapse, cut width, cut perpendicularity, cut surface roughness. | Burr formation, cut surface perpendicularity, roughness, cut edge collapse, cut width, cut perpendicularity, cut surface roughness. |

Cutting Efficiency | Low, suitable for thin and medium-thick plates. | Low, suitable for cutting thin metal sheets. | High efficiency. |

Low maintenance minimizes downtime and costs. | Automotive, aerospace, shipbuilding, metal processing, 3D printing. | Mechanical manufacturing, metal processing. | Precision machining in industrial production. |

Suitability | Oxygen cutting of low-carbon steel: mainly for thin and medium-thick metal plates; widely used in industrial oxygen cutting. | Widely used in metal processing for oxygen cutting. | Widely used in industrial oxygen cutting. |

Notes | Oxygen cutting of low-carbon steel: mainly for thin and medium-thick metal plates; widely used in industrial oxygen cutting. | Widely used in metal processing for oxygen cutting. | Widely used in industrial oxygen cutting. |

The Future of Laser Cutting

Laser cutting’s precision, adaptability, and efficiency ensure its continued dominance in industrial applications. With advancements in fiber laser cutters and CNC cutting machines, the technology is poised for even broader adoption. From automotive to aerospace, laser cutting’s ability to handle diverse materials and complex designs makes it a vital tool for modern manufacturing.

V-Grooving Machine

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

- Hydraulic Press Machine

- Read more about Practical Methods for Press Brake Accuracy with Long Term Precision

- Rolling Machine

- Ironworker

- Press Brake Tooling

- Machinery Accessories