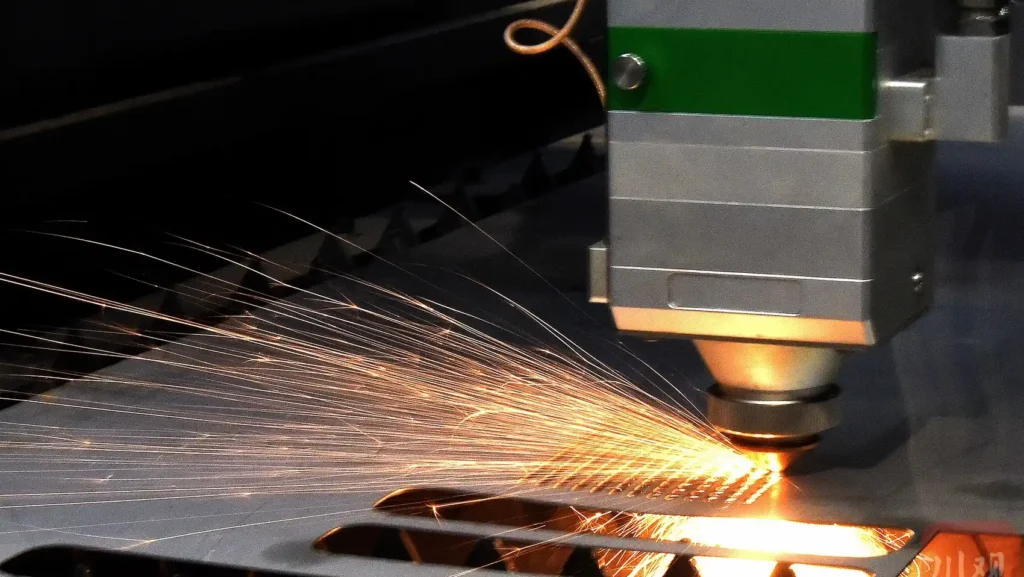

Laser Cutting Burr Problems and Solutions

Laser Cutting Burr Problems and Solutions: Strategies for Achieving Clean Edges on Your Laser Cutting Machine Significant Challenges Posed by Burrs in Laser Cutting Processes Laser cutting machines have become vital assets in metal fabrication workshops, enabling swift, precise shaping of materials including carbon steel, stainless steel, and aluminum alloys. These devices minimize scrap and support intricate designs, contributing to faster production and better overall finishes. However, operators frequently encounter a persistent issue: the development of burrs on the perimeters of cut items. These laser cutting burrs—small, irregular metal fragments or ridges—can detract from the workpiece’s smoothness and usability. The implications of laser cutting burr problems are extensive and impactful. […]

How to Properly Use Press Brake Crowning

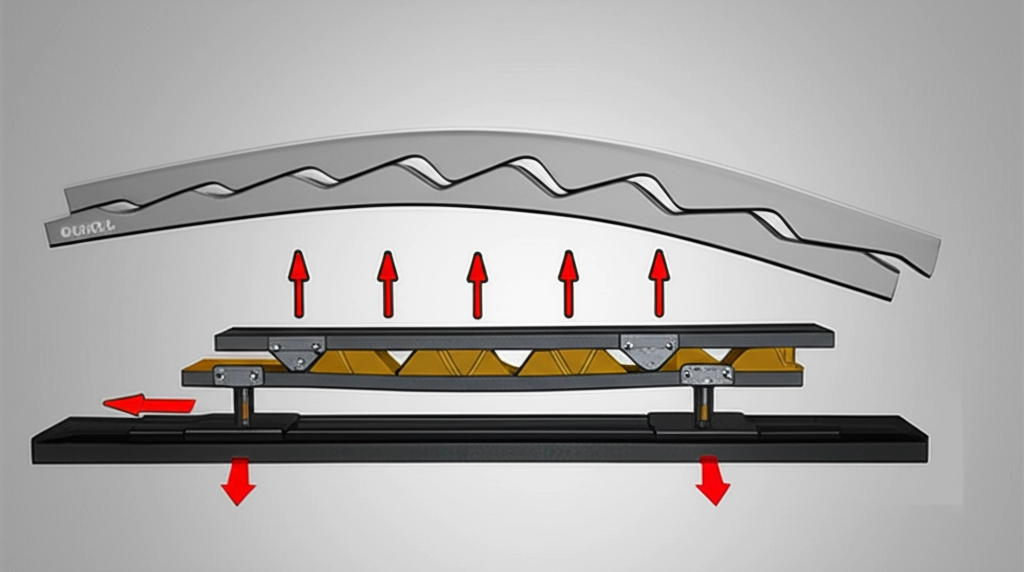

How to Properly Use Press Brake Crowning Press brake crowning is a critical technique that involves adjusting the physical position of the upper or lower tooling to counteract material springback and machine deflection. This ensures precise bends across the entire workpiece length. Studies indicate that up to 90% of bending errors stem from springback, while effective crowning can reduce these inaccuracies by over 70%. Crowning methods fall into two primary categories: Deflection Crowning: Ideal for long workpieces (over 2 meters), this addresses sagging in the middle by using hydraulic cylinders or wedges to lift the lower table. Typical crowning ranges from 0.05-0.3 mm per meter. Angle Crowning: This fine-tunes the […]

How to Correct CNC Press Brake Angles

How to Correct CNC Press Brake Angles In the world of metal fabrication, achieving consistent press brake angles is crucial for producing high-quality parts. If you’re dealing with a CNC press brake where the angles vary across the workpiece—such as one end being sharper than the other—it can lead to wasted materials, rework, and production delays. This guide addresses the user intent behind searches like “how to fix inconsistent angles on CNC press brake” by providing in-depth causes, practical solutions, and expert tips. Drawing from industry standards and real-world troubleshooting, we’ll help you restore accuracy to your CNC press brake operations.As a specialist in CNC machinery with over a decade […]

Press Brake Proportional Valve Repair and Maintenance

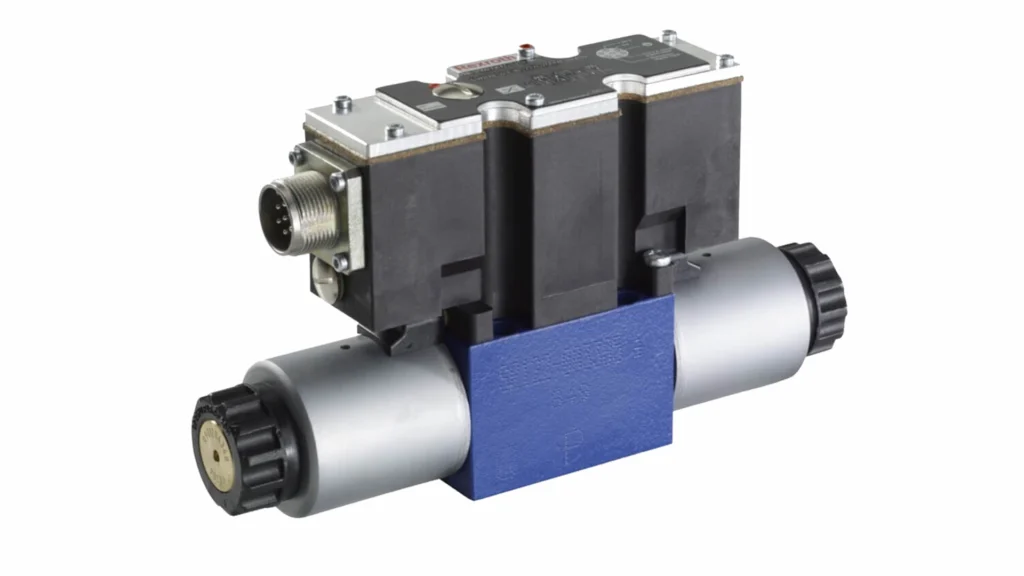

Press Brake Proportional Valve Repair and Maintenance Press brake proportional valves are critical components in hydraulic systems, enabling precise control over fluid flow and pressure based on electronic inputs. These valves enhance accuracy in bending operations, making them indispensable in CNC press brakes and automated manufacturing setups. By converting electrical signals into mechanical movements, they adjust the valve spool to modulate hydraulic output seamlessly. In high-precision environments like metal fabrication, maintaining these valves prevents downtime and boosts productivity. This guide covers their fundamentals, common faults, and proven fixes, drawing from hydraulic engineering best practices. Understanding Press Brake Proportional Valve Definition and Working Principle A press brake proportional valve is an […]

How to Diagnose and Repair Press Brake Cylinder Failures

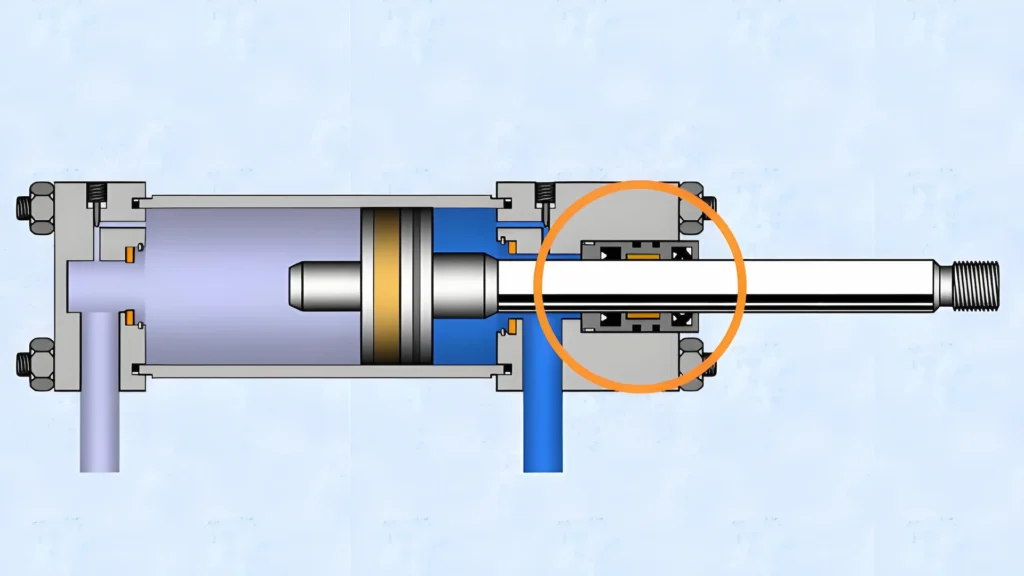

How to Diagnose and Repair Press Brake Cylinder Failures Hydraulic press brake cylinder is the powerhouse behind hydraulic and electro-hydraulic CNC press brakes. It transforms hydraulic energy into mechanical force, driving the ram’s linear motion to shape metal sheets with precision. In sheet metal fabrication, the cylinder’s performance determines the machine’s ability to deliver consistent, high-quality bends. This comprehensive guide dives into the critical role of press brake cylinders, common failure causes, detailed repair methods, synchronization solutions for CNC press brakes, and a robust maintenance plan to maximize uptime and efficiency. Why Press Brake Cylinders Are Critical The hydraulic press brake cylinder is the backbone of bending operations, influencing performance […]

Laser Cutting Gas Role and Selection

Laser Cutting Gas Role and Selection Laser cutting machines have revolutionized precision manufacturing, enabling intricate cuts across materials like metals, plastics, composites, and even ceramics with unparalleled accuracy and efficiency. By focusing a high-energy laser beam onto a material’s surface, these machines cause it to vaporize, melt, or reach its ignition point, creating precise cuts. A critical yet often underappreciated component in this process is the assist gas, which plays a pivotal role in ensuring clean cuts, optimizing machine performance, and achieving material-specific results in laser cutting machine, fiber laser cutter, and CNC laser cutting machine applications. This comprehensive guide explores the multifaceted roles of assist gases, provides actionable insights […]

Finite Element Analysis and Deformation Optimization of Press Brake Frame

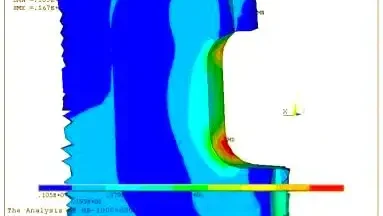

Finite Element Analysis and Structural Optimization of Press Brake Frame Finite element analysis (FEA) is a cornerstone of modern engineering, enabling precise evaluation of structural performance in press brake frame. This article explores the finite element modeling, stress and deformation analysis, and structural optimization of press brake machine bodies. Using ANSYS software, we simplify complex models, apply advanced meshing techniques, define realistic constraints and loads, and optimize designs to achieve uniform stress distribution and material efficiency. This guide provides engineers, manufacturers, and industry professionals with actionable insights to enhance hydraulic press brake performance, ensuring durability and cost-effectiveness. 1. Model Simplification and Optimization Design To balance computational efficiency with analytical accuracy, […]

Guide of Laser Cutting Machine Maintenance

Guide of Laser Cutting Machine Maintenance Laser cutting machine maintenance is crucial for ensuring optimal performance, extending equipment lifespan, and achieving high-quality cuts. A well-maintained machine minimizes downtime, reduces repair costs, and enhances workplace safety. This comprehensive guide outlines daily, weekly, and periodic maintenance tasks, covering everything from optical lens care to laser and chiller maintenance. Whether you’re a technician or a machine operator, this guide provides actionable steps to keep your laser cutting machine in top condition. 1. Daily Laser Cutting Machine Inspection and Maintenance Daily checks and maintenance tasks are essential to prevent minor issues from escalating into costly repairs. Follow these steps before and after operating your […]

Common CNC Press Brake Faults and Solutions

Common CNC Press Brake Faults and Solutions CNC press brakes are critical for precision metal forming, but like any complex machinery, they can encounter faults that disrupt production. This guide provides a comprehensive overview of common mechanical, hydraulic, and electrical issues in CNC press brakes, along with practical solutions to restore functionality. Whether you’re a technician or an operator, understanding these faults and their fixes will enhance equipment reliability and efficiency. 1. Mechanical Faults and Solutions of Press Brake Mechanical issues often arise from wear and tear or improper adjustments. Below are the most frequent mechanical faults in CNC press brakes and their solutions. Fault 1: Excessive Clearance Between Slider […]

Laser Cutting Machine Operation: Safety & Efficiency Guide

Laser Cutting Machine Operation: Safety & Efficiency Guide Laser cutting machine operation safely and efficiently requires strict adherence to protocols to ensure high-quality results and protect both the operator and the equipment. This comprehensive guide details the step-by-step processes for starting and shutting down a laser cutting machine, preparing for cutting tasks, selecting optimal lead-in lines, performing calibrations, and implementing essential safety and maintenance practices. By following these procedures, operators can maximize performance, extend machine lifespan, and maintain a safe working environment. This guide is designed to address common user queries like “how to operate a laser cutting machine” and “laser cutting safety tips,” providing actionable insights for both novice […]