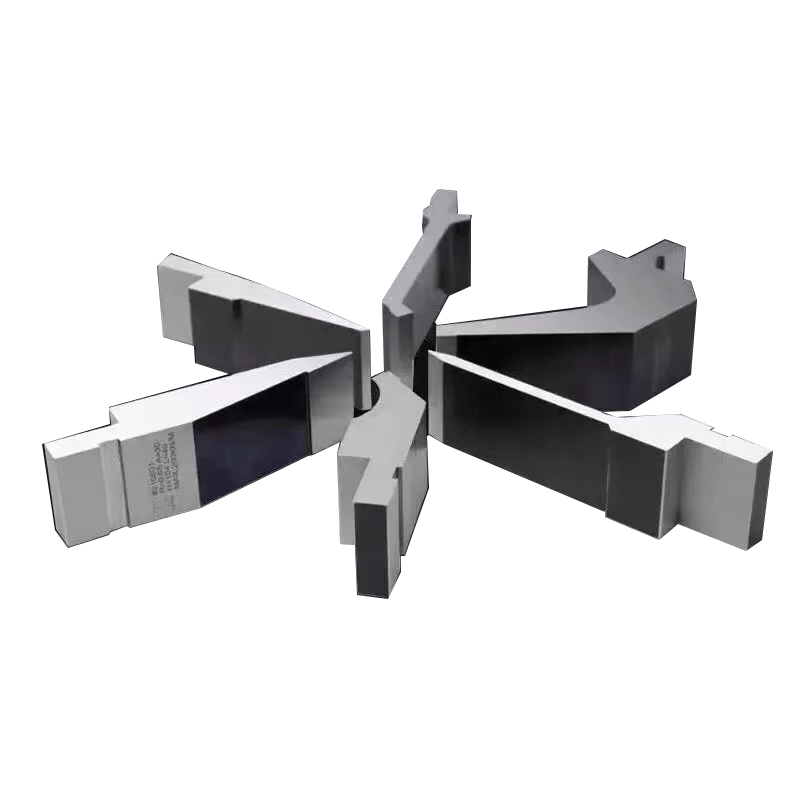

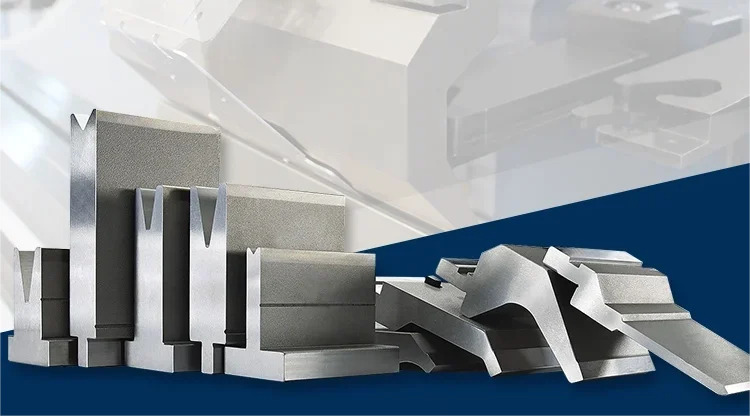

High-quality tooling ensures precise bends, reducing errors and material waste for cost efficiency. Durable designs extend lifespan, lowering maintenance costs. Enhanced repeatability ensures consistent production, while versatile molds handle complex shapes and diverse materials, meeting varied manufacturing demands effectively.

High Precision & Consistency

Durability & LongevityStrengthed Hardness.

Efficient Performance.

cnc control system

Copyright 2025 | All Rights Reserved | CAMTINC