CAMT optimize energy efficiency while delivering superior performance. By integrating a hybrid servo-electric and hydraulic system, this technology significantly reduces energy consumption, ensuring eco-friendly operations without compromising power. The seamless integration of components enhances system efficiency, providing precise positioning at every stage of the bending process. This innovative solution not only lowers operational costs but also supports sustainable manufacturing with its energy-saving design and reliable, high-precision performance.

BackGauge System Selection

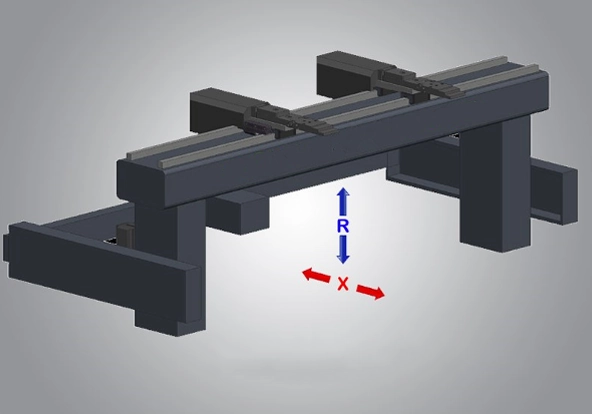

Press Brake 2-Axis CNC BackGauge with X, R-Axis.

X-axis speed reaches 300 mm/s

Manual fingers with CHTR linear guide

- Precision positioning accuracy of ±0.03 mm

- Equipped with fingers featuring double stop and micrometric adjustment

- CAMT 6 AXIS PRESS BRAKE MACHINE

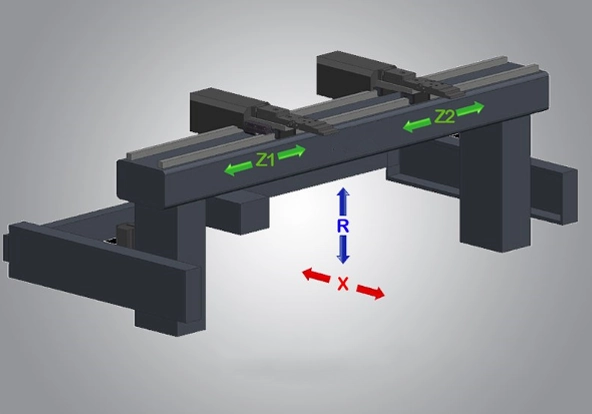

- Press Brake 4-Axis CNC BackGauge with X, R, Z1, Z2-Axis

- AC servo motor control Z1-Z2 automatic movement.

Z1-Z2 axis speed up to 600 mm/s

CAMT 8 AXIS PRESS BRAKE MACHINE

- Press Brake 6-Axis CNC BackGauge with X1, X2, R1, R2, Z1, Z2-Axis.

- Precision positioning accuracy of ±0.03 mm

- Press Brake 4-Axis CNC BackGauge with X, R, Z1, Z2-Axis

- Equipped with fingers featuring double stop and micrometric adjustment

- Z1-Z2 axis speed up to 600 mm/s

- AC servo motor control Z1-Z2 automatic movement.

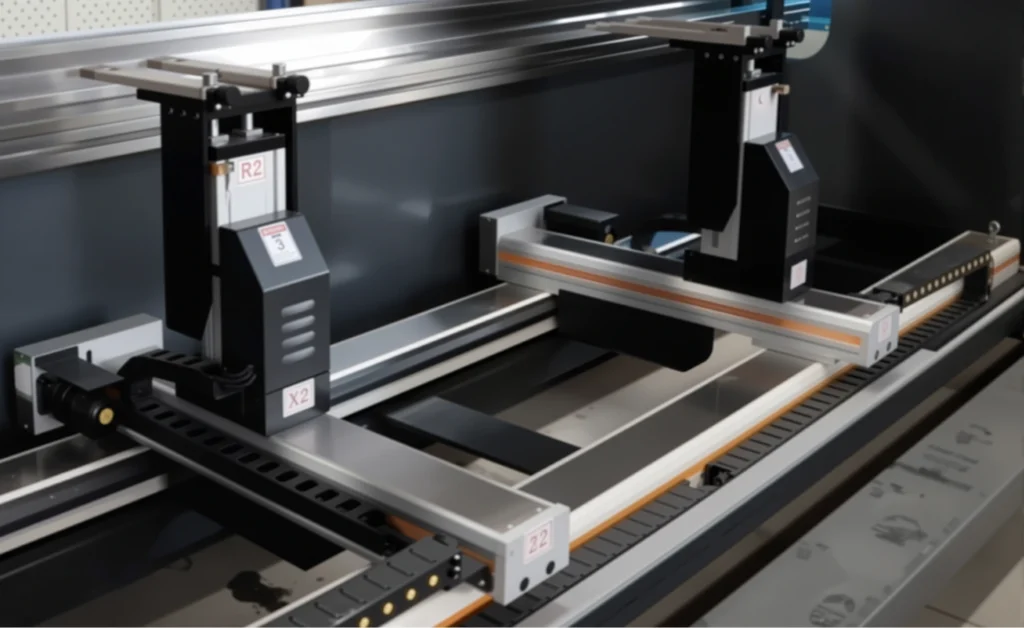

CAMT 8 AXIS PRESS BRAKE MACHINE

Press Brake 6-Axis CNC BackGauge with X1, X2, R1, R2, Z1, Z2-Axis

- Precision positioning accuracy of ±0.03 mm

- Press Brake 6-Axis CNC BackGauge with X1, X2, R1, R2, Z1, Z2-Axis.

- AC servo motor control Z1-Z2 automatic movement.

- Press Brake 4-Axis CNC BackGauge with X, R, Z1, Z2-Axis

- X1-X2-axis speed reaches 600 mm/s

- Z1-Z2 axis speed up to 1000 mm/s

- R1-R2 axis speed up to 500 mm/s