How to Choose the Right Press Brake System

$20,000–$35,000 Aerospace, automotive high-precision ESA (S.A.N.C.).

Hybrid/electric optimization, advanced servo integration.

$18,000–$30,000

Electric press upgrades.

Mid-Range

Beckhoff (TwinCAT), Bosch Rexroth (Cytronic)

- Open architecture, customizable PLCs, strong networking $10,000–$20,000.

- Custom automation, mid-volume WILA (Smart Tooling integration).

- Tooling-focused, user-friendly for mixed batches $8,000–$15,000.

- General fabrication Entry-Level.

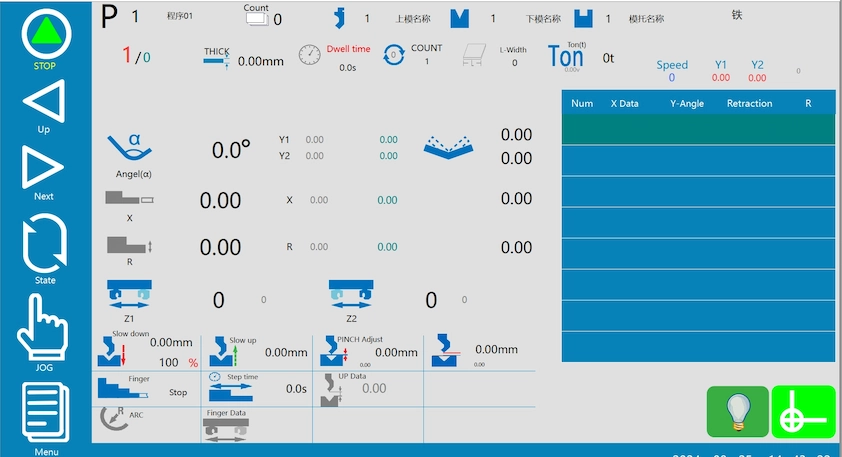

Generic OEM (e.g., Chinese/ Taiwanese like CypCut), Basic Hydrapower.

Simple CNC, manual overrides, cost-effective basics

$3,000–$8,000.

- Low-volume, starter shops Premium Brands:.

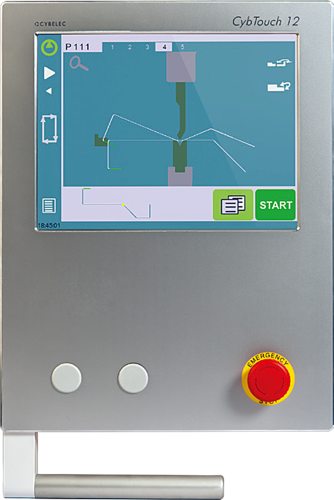

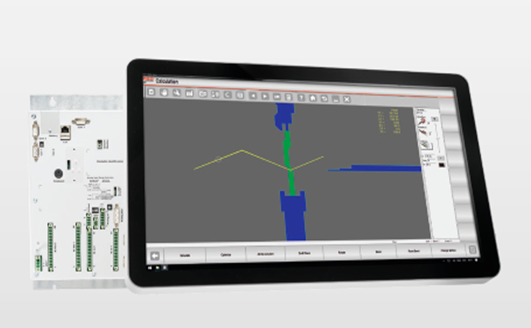

- Cybelec’s stability shines in 24/7 ops; Delem’s DA series dominates with 50% market share (per 2024 SEMI reports) for its bend simulation wizardry. Mid-Range:.

- Beckhoff’s PC-based openness lets coders tweak for IoT. Rexroth excels in rugged environments. Entry-Level:.

Solid for startups, but upgrade paths are limited. Domestic brands like those from Accurl offer value with growing software support.

Match to your scale: Premium for ROI in precision; entry for bootstraps.

Step-by-Step Guide to Selecting Your Press Brake Control System.

Don’t wing it—follow this roadmap for a regret-free buy.

1.Define Your Requirements List:

Jot down specs: Tolerances (±0.2° angles?), materials (mild steel up to 12mm?), volume (500 pcs/week?), budget ($15K max). List must-haves like 3D sim or robot I/O.

2.Research Models:

Use tools like Ahrefs or Google for reviews. Shortlist 3–5: E.g., Delem for versatility, CypCut for budget. Download datasheets—cross-check axis specs.

- 3.Request Quotes and Proposals: Hit up distributors for tailored bids. Ask for ROI calcs (e.g., payback in 18 months via efficiency).

- 4.Review Demos and Videos: YouTube or supplier portals show real workflows. Watch for lag in touch response or sim accuracy.

- 5.Hands-On Testing (Essential): Visit trade shows like FABTECH or factories. Bring sample drawings—test a bend sequence. Measure outputs with calipers for true precision.

6.Vet Support and Service:.

Query response times (under 24hrs?), local techs, and update policies. Check forums like Practical Machinist for user gripes.

7.Weigh and Decide:.

- Score options on a matrix: 40% performance, 20% ease, 20% cost, 10% support, 10% scalability. Pull the trigger on the balanced winner.This process, honed from years advising shops, typically saves 15–20% on mismatched buys.

- Key Considerations and Common Pitfalls Even pros trip up—here’s how to sidestep.

- Beyond Price: A $4K system might nickel-and-dime you with $10K annual downtime. Calculate TCO: Initial + maintenance + training.

Scalability:.

Will it handle tomorrow’s robot arm? Modular systems future-proof.

Training Investment:.

- Allocate 8–16 hours per operator. Intuitive UIs cut this, but budget $500–$1,000 for certs. Machine Matching:.

- Stick to OEM-recommended pairings. Aftermarket? Test compatibility rigorously. True Metrics:.

- Accuracy and Efficiency: Judge by output—consistent bends at speed—not specs. Aim for <5% variance in angle runs. In essence, the best press brake system harmonizes your now with your next. High-precision demands scream for elites like Delem; everyday wins go to value mids like Beckhoff.

- Empower Your Bends with the Right Choice Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow.

Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow.

blog

cnc control system.

- press brake safety 6.Vet Support and Service:.

- Query response times (under 24hrs?), local techs, and update policies. Check forums like Practical Machinist for user gripes. 7.Weigh and Decide:.

- Score options on a matrix: 40% performance, 20% ease, 20% cost, 10% support, 10% scalability. Pull the trigger on the balanced winner.This process, honed from years advising shops, typically saves 15–20% on mismatched buys.

Key Considerations and Common Pitfalls.

Even pros trip up—here’s how to sidestep.

Beyond Price:.

- A $4K system might nickel-and-dime you with $10K annual downtime. Calculate TCO: Initial + maintenance + training. Scalability:.

- Will it handle tomorrow’s robot arm? Modular systems future-proof. Training Investment:.

- Allocate 8–16 hours per operator. Intuitive UIs cut this, but budget $500–$1,000 for certs. Machine Matching:.

Stick to OEM-recommended pairings. Aftermarket? Test compatibility rigorously.

True Metrics:

Accuracy and Efficiency: Judge by output—consistent bends at speed—not specs. Aim for <5% variance in angle runs.

In essence, the best press brake system harmonizes your now with your next. High-precision demands scream for elites like Delem; everyday wins go to value mids like Beckhoff. | Empower Your Bends with the Right Choice | Picking a press brake system boils down to that sweet spot: Meeting demands without budget bloat. Elite setups with closed-loop magic transform precision shops, while solid mids keep general fab humming affordably. Whatever your path, prioritize trials—nothing beats feeling the flow. | Ready to bend smarter? Audit your setup today, shortlist smartly, and watch your throughput soar. For custom advice, drop a line—I’ve seen these systems turn chaos into cash flow. | Read more about Principle and Function of Press Brake Safety Protection System |

Read more about Press Brake Maintenance and Repair | Read more about Practical Methods for Press Brake Accuracy with Long Term Precision | Read more about Practical Guidance For Press Brake Operation | Read more about How to Properly Install a Press Brake Machine | Аэрокосмическая, автомобильная высокоточная |

Read more about Press Brake Maintenance and Repair | ESA (S.A.N.C.) | Гибридная/электрическая оптимизация, расширенная интеграция сервоприводов | $18,000–$30,000 | Модернизация электрических прессов |

Средний уровень | Beckhoff (TwinCAT), Bosch Rexroth (Cytronic) | Открытая архитектура, настраиваемые ПЛК, мощные сетевые возможности | $10,000–$20,000 | Индивидуальная автоматизация, средний объем |

Средний уровень | WILA (интеграция Smart Tooling) | Ориентированный на оснастку, удобный для пользователя для смешанных партий | $8,000–$15,000 | Общее производство |

Начальный уровень | Стандартный OEM (например, китайский/тайваньский, как CypCut), Basic Hydrapower | Простое ЧПУ, ручное управление, экономичные базовые функции | $3,000–$8,000 | Небольшие объемы, начинающие мастерские |

- Премиум-бренды: Стабильность Cybelec проявляется в круглосуточной работе; серия DA от Delem доминирует с 50% долей рынка (по отчетам SEMI за 2024 год) благодаря своему мастерству в симуляции гибки.

- Средний сегмент: Открытость Beckhoff на базе ПК позволяет программистам настраивать его для IoT. Rexroth превосходен в суровых условиях.

- Начальный уровень: Надежен для стартапов, но возможности обновления ограничены. Отечественные бренды, такие как Accurl, предлагают ценность с растущей поддержкой программного обеспечения.

Подбирайте по своему масштабу: Премиум для окупаемости инвестиций в точность; начальный уровень для стартапов с ограниченным бюджетом.

Пошаговое руководство по выбору системы управления листогибочным прессом

Не действуйте наугад — следуйте этой дорожной карте для покупки без сожалений.

1. Определите список требований: Запишите характеристики: Допуски (углы ±0,2°?), материалы (мягкая сталь до 12 мм?), объем (500 шт/неделю?), бюджет (макс. 15 тыс. $). Перечислите обязательные функции, такие как 3D-симуляция или ввод/вывод робота.

2. Исследуйте модели: Используйте такие инструменты, как Ahrefs или Google, для поиска отзывов. Составьте шорт-лист из 3–5: Например, Delem для универсальности, CypCut для бюджета. Загрузите технические паспорта — перепроверьте характеристики осей.

3.Запросите расценки и предложения: Обратитесь к дистрибьюторам за индивидуальными предложениями. Запросите расчеты ROI (например, окупаемость за 18 месяцев за счет эффективности).

4.Просмотрите демонстрации и видео: YouTube или порталы поставщиков показывают реальные рабочие процессы. Следите за задержками в реакции на касание или точности симуляции.

5.Практическое тестирование (обязательно): Посетите выставки, такие как FABTECH, или заводы. Возьмите образцы чертежей — протестируйте последовательность гибки. Измерьте результаты штангенциркулем для истинной точности.

6.Проверьте поддержку и обслуживание: Узнайте время ответа на запросы (менее 24 часов?), наличие местных техников и политику обновлений. Проверьте форумы, такие как Practical Machinist, на предмет жалоб пользователей.

7.Взвесьте и примите решение: Оцените варианты по матрице: 40% производительность, 20% простота использования, 20% стоимость, 10% поддержка, 10% масштабируемость.

Выберите сбалансированного победителя. Этот процесс, отточенный годами консультирования цехов, обычно экономит 15–20% на неудачных покупках.

Ключевые соображения и распространенные ошибки

Даже профессионалы спотыкаются — вот как этого избежать.

- Помимо цены: Система за $4K может обойтись вам в $10K ежегодных простоев. Рассчитайте TCO: Начальные затраты + обслуживание + обучение.

- Scalability: Справится ли она с завтрашней роботизированной рукой? Модульные системы обеспечивают перспективность.

- Инвестиции в обучение: Выделите 8–16 часов на оператора. Интуитивно понятные пользовательские интерфейсы сокращают это время, но заложите в бюджет 500–1000 долларов на сертификацию.

- Соответствие оборудования: Придерживайтесь рекомендованных производителем комплектаций. Вторичный рынок? Тщательно проверяйте совместимость.

- Истинные показатели: Точность и эффективность: Оценивайте по результату — стабильные гибы на скорости, а не по характеристикам. Стремитесь к отклонению угла менее 5%.

По сути, лучшая система листогибочного пресса гармонизирует ваше настоящее с вашим будущим. Высокоточные требования взывают к элитным системам, таким как Delem; повседневные победы достаются среднеценовым решениям, таким как Beckhoff.

Расширьте возможности своих гибов с правильным выбором

Выбор системы листогибочного пресса сводится к поиску золотой середины: удовлетворение требований без раздувания бюджета. Элитные установки с магией замкнутого контура преображают прецизионные цеха, в то время как надежные среднеценовые решения поддерживают работу общего производства доступно. Каким бы ни был ваш путь, отдавайте приоритет испытаниям — ничто не сравнится с ощущением потока.

Готовы гнуть умнее? Проведите аудит своей установки сегодня, составьте умный шорт-лист и наблюдайте, как ваша производительность взлетает. За индивидуальной консультацией обращайтесь — я видел, как эти системы превращают хаос в денежный поток.

All Products.

V-Grooving Machine

- Press Brake

- Laser Cutting Machine

- Shearing Machine

- Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

- Hydraulic Press Machine

- Read more about Practical Methods for Press Brake Accuracy with Long Term Precision

- Rolling Machine

- Ironworker

- Press Brake Tooling

- Machinery Accessories