Enhanced Precision: The 835mm segmented CNC concentric mold design ensures precise centering, improving accuracy for complex bending tasks.

Popular Synchronous Press Brake Smart 3-4 Axis

CAMT optimize energy efficiency while delivering superior performance. By integrating a hybrid servo-electric and hydraulic system, this technology significantly reduces energy consumption, ensuring eco-friendly operations without compromising power. The seamless integration of components enhances system efficiency, providing precise positioning at every stage of the bending process. This innovative solution not only lowers operational costs but also supports sustainable manufacturing with its energy-saving design and reliable, high-precision performance.

Popular Synchronous Press Brake Smart 3-4 Axis

Delivers real-time feedback and micron-level precision.

Boosts efficiency with 20% faster response than hydraulic systems.

Eco-friendly design with regenerative power recovery.

Advanced technology for superior performance.

Backed by professional engineers for lifelong assurance.

breadcrumbs

crowning system

crowning system

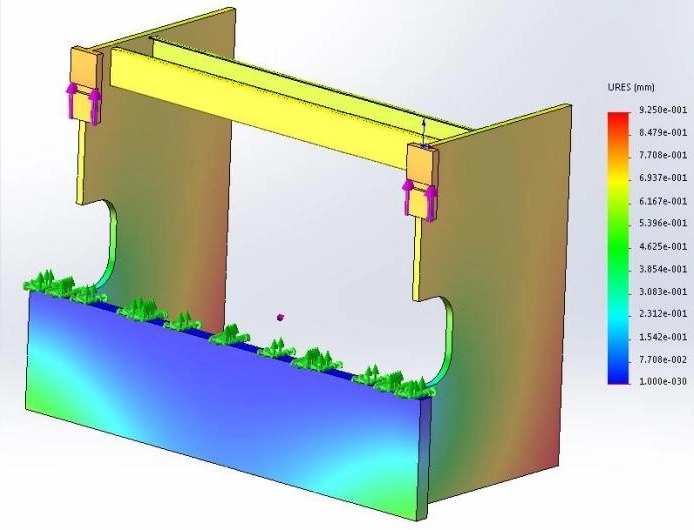

CAMT FEA plays a pivotal role by optimizing structures through stress distribution analysis to identify and reinforce high-stress areas, enhancing strength while minimizing material waste; verifying performance by predicting deformation under extreme loads (e.g., 600 tons) to ensure precision and stability for Y1/Y2 synchronization; assessing safety by evaluating stress concentration to mitigate fatigue or fracture risks for long-term reliability; and conducting dynamic analysis to simulate transient loads and vibrations in complex scenarios like tandem bending or high-speed operations, optimizing servo motor response and overall machine stability.

Overseas After-Service Support Bending System

Taiwan TECHMATION SCS700 Automation

Utilizes high-precision industrial-grade color touch screen

High Customization

- Utilizes platform industrial-grade display

- Newly developed industrial-grade MEC4 embedded version, customizable

- Supports multiple expansion options: color, machine motion control, USB port (image loading), CAN expansion, etc. Optional features.

- Stragetic Cooperation with DELEM/CYBELEC to Satisfied Usage Habit

- DELEM DA53T Touch CNC System

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- CAMT CHTR Rear BackGauge

- Standard X&R Axis with High Performace Linear Guide

- Enables precise backGauge positioning with an accuracy of typically ±0.01mm, suitable for high-precision bending needs.

BackGauge speed up to 300 mm/s with a precise positioning accuracy.

FEA accurately predicts stress distribution patterns, deformation characteristics, and load-bearing capacities under various operating conditions. This advanced analytical approach enables engineers to identify and reinforce potential weak points in the frame, ram, and bed assembly while optimizing material usage through topology optimization techniques. The analysis specifically targets critical performance factors including ram deflection compensation accuracy, structural vibration damping, and fatigue resistance under cyclic loading conditions. Through iterative simulation processes, FEA facilitates the development of press brakes with enhanced rigidity-to-weight ratios, improved energy efficiency, and prolonged service life.

Automated programming and operation, reducing manual intervention and suiting mass production.

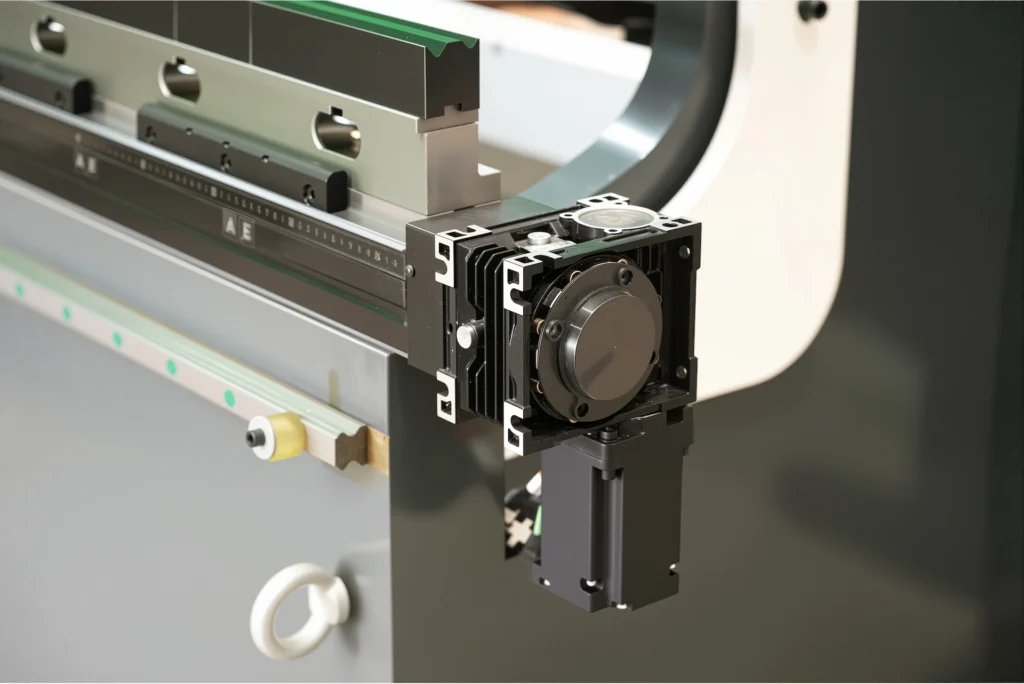

GIVI MISURE

- Italy Importaed Maganetic Ruler - Precise Postioning and On-time Reaction

- High-precision measurement (with resolution down to 1μm), rapid response, robust resistance to environmental interference, and durable, low-maintenance performance. Its non-contact design thrives in harsh working conditions, while supporting multi-axis control and various interface protocols, ensuring seamless integration with CNC systems and enhancing automation. The GIVI magnetic scale significantly boosts the bending machine’s positioning accuracy, production efficiency, and reliability, meeting the stringent demands of modern metal processing.

- Optional Safety Arrangement - Light Curtain

- Effectively preventing injuries during bending processes.

- Up to EN 12622 meet legal requirements and avoid liability issues.

- Enabling safe and efficient workflows by detecting intrusions in real time.

Flexibility for Diverse Applications

High safety standards, Ahieve SIL 3 (Safety Integrity Level 3)

- ESA S660W CNC System

- “A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

- Mitigates deformations in the worktable and slider due to applied forces, ensuring uniform bending angles and improved machining precision, particularly for long and diverse workpieces. Multi-point mechanical compensation, with independently adjustable points along the worktable’s length, precisely controls deformation in each segment, significantly enhancing straightness and consistency for extended workpieces

- Tool and die holders’ management.

- 19 inch LCD touch screen (Capacitive).

- Stander to 4 axis, can up to 156 axis max.

- ESA S675W CNC System

- 21 inch LCD touch screen (Capacitive)

Tandem machine management(option, can up to 4 machines)

ESA S650W 2D Graphical CNC System

- No limit in both performances and flexibility.

- "The powerful built-in Pc allows having on the machine a real 3D cad cam (metallix, radan, esa)

- Finger-tip work piece design.

- Direct import of tools shapes (.dxf files) and management of tool library.

- Tool and die holders management.

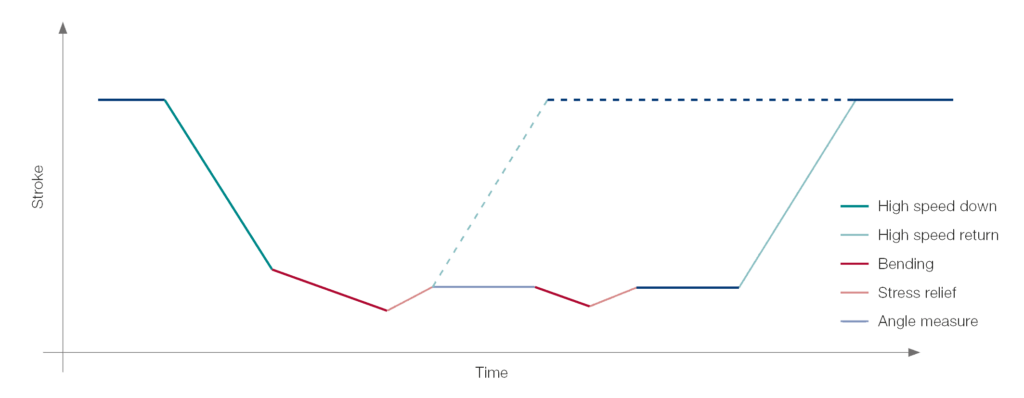

- Angle measurement and correction with all existing devices is available.

Delivers real-time feedback and micron-level precision.

Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.

- breadcrumbs.

- hybrid servo eco system function.

GIVI MISURE

Italy Importaed Maganetic Ruler - Precise Postioning and On-time Reaction

Optional Safety Arrangement - Light Curtain

- Effectively preventing injuries during bending processes.

- Up to EN 12622 meet legal requirements and avoid liability issues.

- Enabling safe and efficient workflows by detecting intrusions in real time

- High Sensitivity and Accuracy

- Flexibility for Diverse Applications

- High safety standards, Ahieve SIL 3 (Safety Integrity Level 3)

- Supporting efficient production

Improves Precision: Multi-point mechanical crowning allows independent adjustments across the worktable’s length, precisely managing deformation in each section for superior straightness and uniformity in extended workpieces.

Precise Effectiveness & Muti-Point Crowning of Press Brake Machine

China Strict Inspection Hydraulic Press Brake Oil Cylinder

- High Durability: High-quality steel and undergoes meticulous processing, ensuring exceptional durability, strong compressive strength, and substantial weight to withstand heavy-duty operations.

- Simplified Operation: Effectively reducing on-site setup time and extending the lifespan of components.

- Comprehensive Capabilities: Robust quality control and inspection system during production, ensuring that finished workpieces meet standards while maintaining complete functionality and smooth operation.

- Structural Compactness: Compact yet sturdy design, with a tight structure that ensures efficient storage and operation, enhancing support effectiveness.

- Ease of Maintenance: Convenience, offering easy maintenance, user-friendly operation, and a longer service life, minimizing on-site labor and manpower requirements.

Bending Tool & Fast Clamping:

Special tools mode

- Superior Tooling Durability: Crafted from 42CrMo steel, the tooling undergoes high-temperature forging and quenching to achieve a hardness of 47-49HRC, delivering exceptional bending performance and resilience across diverse working conditions.

- Enhanced Precision: The 835mm segmented CNC concentric mold design ensures precise centering, improving accuracy for complex bending tasks.

- Efficient Tool Changes: Features a quick-clamp system for rapid tool replacement, supporting both front (vertical) and rear (horizontal) configurations, increasing operational efficiency and reducing labor requirements.

- Versatile Compatibility: Designed to seamlessly accommodate European-style punches without modification, offering flexibility for various applications.

CAMT Itergral Hydraulic System

Advanced Hybrid Servo ECO Technology for Press Brake Machine

Special tools mode

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.