CAMT optimize energy efficiency while delivering superior performance. By integrating a hybrid servo-electric and hydraulic system, this technology significantly reduces energy consumption, ensuring eco-friendly operations without compromising power. The seamless integration of components enhances system efficiency, providing precise positioning at every stage of the bending process. This innovative solution not only lowers operational costs but also supports sustainable manufacturing with its energy-saving design and reliable, high-precision performance.

Y32 4 Column Hydraulic Press Machine

CAMT optimize energy efficiency while delivering superior performance. By integrating a hybrid servo-electric and hydraulic system, this technology significantly reduces energy consumption, ensuring eco-friendly operations without compromising power. The seamless integration of components enhances system efficiency, providing precise positioning at every stage of the bending process. This innovative solution not only lowers operational costs but also supports sustainable manufacturing with its energy-saving design and reliable, high-precision performance.

Y32 4 Column Hydraulic Press Machine

Flexible Operation.

CAMT Powerful Press Solution.

crowning system

crowning system

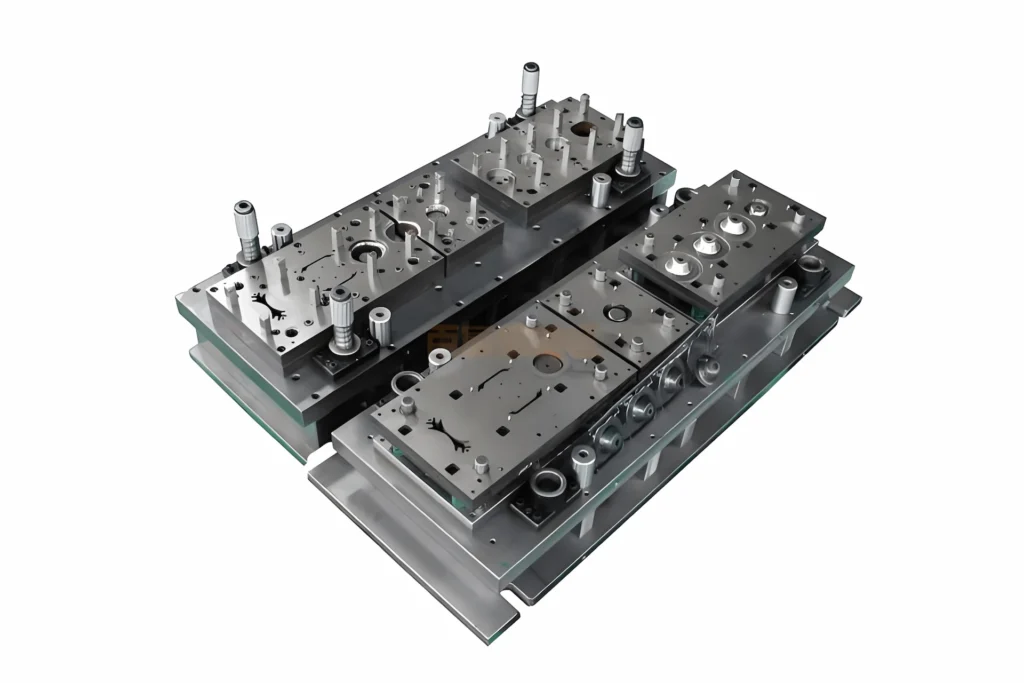

Structure design is optimized by computer, with three-beam andfour column structure; this equipment is simple, economic and useful.

Hydraulic control adopt insert type compact valve system, with reliable operation, long service life, minimized hydraulic shock, minimized duct connection and possible leak point.

Independent electric control system which is reliable, direct-in-running, and convenient for maintaining.

Adopt concentrated button control system, which is adjustable and has two operation models, viz. both hands model and single circulation model.

Two operation model, viz. pressure regulation and stroke regulation which can be selected through operational panel, and has the character of pressure-keeping and time-delaying.

Work pressure and stroke can be adjusted according to the requirement within the specified range.

Press Application About Press Machine

Widely used in the following industries

- Metal Processing: Stamping, stretching, riveting, pressing, and straightening.

- Plastic Products: Compression molding, SMC/BMC composite material pressing.

- Powder Metallurgy: Metal powder compaction.

- Rubber Industry: Vulcanization and compression molding.

- Automotive Manufacturing: Component processing, bearing pressing.

- Building Materials: Refractory brick and ceramic product pressing.

Y32-63

Y32-100

- Y32-200.

- Y32-315.

- Y32-400.

- Y32-500.

- Y32-600A.

- Y32-630.

| 60X60X8 | Y32-1000 | Nominal force (kN) | Ejecting force (kN) | Return force (kN) | Slider stroke (mm) | Ejecting stroke (mm) | Max. opening height (mm) | Slider speed - Idle down (mm/s) | Slider speed - Work (mm/s) | Slider speed - Return (mm/s) |

|---|---|---|---|---|---|---|---|---|---|---|

| Ejecting speed - Eject (mm/s) | 630 | 1000 | 2000 | 3150 | 4000 | 5000 | 5000 | 6300 | 8000 | 10000 |

| Ejecting speed - Back (mm/s) | 100 | 250 | 400 | 630 | 630 | 1000 | 1000 | 1000 | 1000 | 1250 |

| Workbench size - L-R (mm) | 125 | 320 | 450 | 600 | 600 | 1000 | 1000 | 1000 | 1200 | 1250 |

| Workbench size - F-B (mm) | 500 | 600 | 700 | 800 | 800 | 900 | 900 | 900 | 1000 | 1000 |

| Poles distance - L-R (mm) | 160 | 200 | 250 | 300 | 300 | 355 | 355 | 355 | 350 | 350 |

| Poles distance - F-B (mm) | 800 | 900 | 1200 | 1250 | 1250 | 1500 | 1500 | 1500 | 1800 | 1800 |

| Dimension - L-R (mm) | 100 | 100 | 100 | 100 | 100 | 120 | 80 | 120 | 120 | 120 |

| Dimension - F-B (mm) | 9 | 10 | 12 | 12 | 12 | 12 | 12 | 10 | 10 | 10 |

| Height on ground (mm) | 50 | 50 | 50 | 60 | 60 | 80 | 70 | 50 | 100 | 100 |

| Motor power (kW) | 50 | 80 | 60 | 60 | 60 | 80 | 80 | 65 | 65 | 65 |

| Four-column structure provides excellent rigidity and anti-eccentric load capacity, ensuring long-term precision operation. | 100 | 160 | 120 | 100 | 100 | 200 | 200 | 200 | 140 | 140 |

| Available in capacities ranging from tens to thousands of tons to meet diverse industrial needs. | 520 | 720 | 900 | 1120 | 1250 | 1400 | 2200 | 1600 | 2200 | 2500 |

| Equipped with variable pumps or servo hydraulic systems to reduce energy consumption and improve efficiency. | 490 | 580 | 900 | 1120 | 1250 | 1400 | 1600 | 1600 | 1600 | 1800 |

| Supports multiple working modes with adjustable parameters for various process requirements. | 650 | 800 | 1140 | 1140 | 1500 | 1700 | 2620 | 1950 | 2600 | 2900 |

| Multi-layer safety protection minimizes equipment failure and operational risks. | 350 | 430 | 660 | 900 | 1000 | 1120 | 1120 | 1200 | 1200 | 1350 |

| Modular design allows for quick inspection and replacement of key components. | 900 | 1100 | 1380 | 1160 | 3600 | 3900 | 4700 | 5200 | 6600 | 4650 |

| breadcrumbs | 500 | 800 | 900 | 1660 | 2300 | 3600 | 3600 | 4600 | 2600 | 2650 |

| Высота от земли (мм) | 2400 | 2600 | 2725 | 4295 | 4500 | 5220 | 5220 | 6000 | 7200 | 6570 |

| Мощность двигателя (кВт) | 7.5 | 11 | 15 | 22 | 30 | 44 | 45 | 60 | 90 | 90 |

Special tools mode

- Четырехстоечная конструкция обеспечивает превосходную жесткость и устойчивость к эксцентрическим нагрузкам, гарантируя длительную и точную работу.

- Доступны в диапазоне мощностей от десятков до тысяч тонн для удовлетворения разнообразных промышленных потребностей.

- Оснащены регулируемыми насосами или сервогидравлическими системами для снижения энергопотребления и повышения эффективности.

- Поддерживает несколько режимов работы с регулируемыми параметрами для различных технологических требований.

- Многоуровневая система безопасности минимизирует отказы оборудования и эксплуатационные риски.

- Модульная конструкция обеспечивает быструю проверку и замену ключевых компонентов.