CAMT

Tandem Press Brake with Dual Linkage Solution

CAMT

CAMT Dual Linkage Press Brake

Suitbale Bending Solution for Long sheet Metal Fabrication

CAMT core of the tandem press brake bending machine lies in the synchronized movement of two bending machines achieved through a numerical control system (CNC) or an electro-hydraulic servo system. The two machines are typically arranged in parallel or opposite each other, sharing a single control system. High-precision sensors and servo valves ensure that the sliders of both machines are perfectly aligned in terms of motion trajectory, speed, and pressure.

Suitable for bending ultra-long and ultra-wide plates, such as those used in ships, bridges, and architectural structures. It enables complex shape processing by allowing coordinated operation of two machines to achieve intricate bending angles and multi-stage bends. It enhances production efficiency by simultaneously processing multiple workpieces or a single large workpiece, reducing processing time. Additionally, the synchronized control system ensures uniform force distribution at both ends, preventing workpiece deformation or angle deviations.

Tandem press brake

achieves coordinated operation of two bending machines through synchronous control technology, making it particularly suitable for processing large, complex, and high-precision metal plates. Its high efficiency, accuracy, and flexibility provide significant advantages in heavy industry and high-end manufacturing.

Add Your Tooltip Text Here

Add Your Tooltip Text Here

Preferential Quality with Less Error Rate

Faster Working Efficiency

Eco-friendly;40% Energy Saved

More Refined Y1/Y2 Control Effect

Popular Configuration

- 21.6-inch color high-definition touch screen with friendly human-machine interface

- CHTR Rear BGA 600MM with 300MM/S

- 4 V Double CNC die series &835mm punches

- High Precision & Multi Point Mechanical Crowning

- Imported Italy GIVI Maganetic Misure

- FULL Close-loop High Performance Hydrauic System

- All-In-One Effective Servo Motor

- Graphite Self-lubricating Copper Plate

- Safety France Schneider Electric System Components

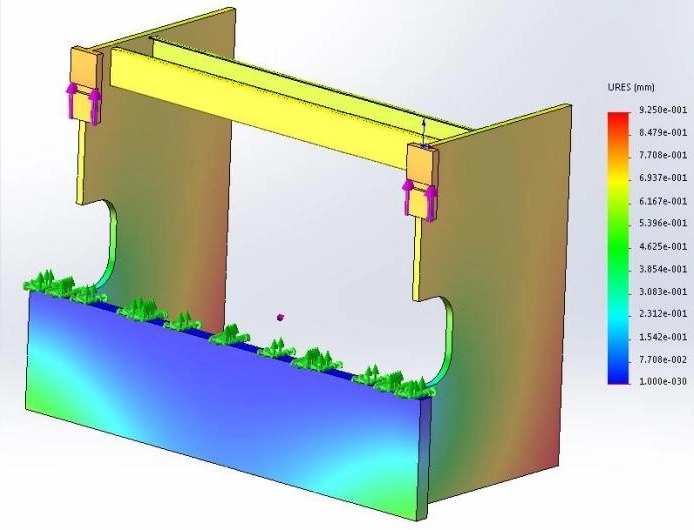

FEA & Stress Analysis of Press Brake

Stress Analysis & Finite Element Analysis

Overseas After-Service Support Bending System

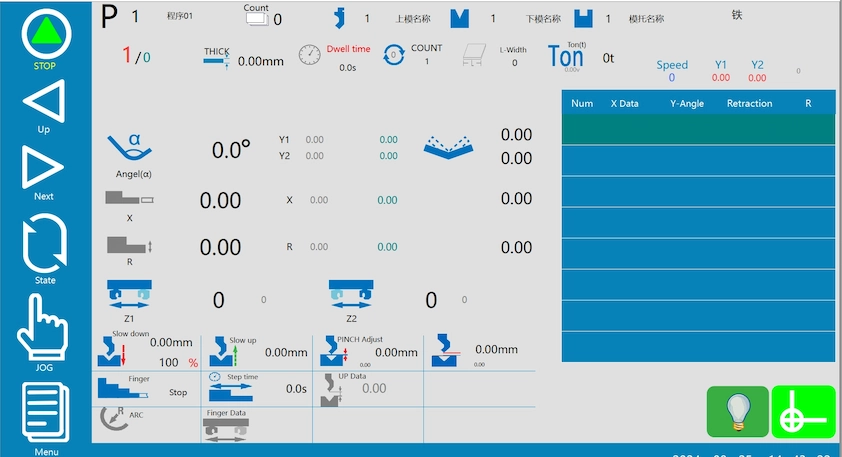

Taiwan TECHMATION SCS700 Automation

- Utilizes high-precision industrial-grade color touch screen

- Comes with SECOT dual-language version (supports logo or image customization)

- Supports one-button color switching, approximately 1024*768 resolution

- Utilizes platform industrial-grade display

- Newly developed industrial-grade MEC4 embedded version, customizable

- Supports multiple expansion options: color, machine motion control, USB port (image loading), CAN expansion, etc. Optional features.

Stragetic Cooperation with DELEM/CYBELEC to Satisfied Usage Habit

DELEM DA53T Touch CNC System

- 10.1" high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 Axis (Y1,Y2 + 2 aux. Axis)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

Intergral Advanced CNC Control System

More Than 10 Years R&D CNC Control

- 21..6-inch color high-definition touch screen with friendly human-machine interface

- "One-page" programming navigation, one page can display all data, and it isfaster to modify the curve information

- The system supports 4-axis control, meeting the highest control conditions of 4+1+2 axis bending machine

- The Linux operating platform is stable and reliable, with fast startup speeddand can be directly powered off and shut down

- The bending data is automatically calculated, the bending speed of each step is programmable, the slow down and mid-stop can be controlled, and thehome page has convenient functions such as fast mold alignment, so novicescan quickly get started

- Rich interfaces, can be easily and conveniently connected to the automateddproduction line as a bending unit

CAMT Dual Linkage Device

Composition of the Tandem Press Brake

- As the core of synchronous control, it directs the movements of both bending machines through preset programs. It integrates high-precision algorithms to calculate the slider's position and angle in real time.

- Includes grating rulers, encoders, or laser rangefinders to detect the slider's position and angle in real time. Provides feedback data to the CNC system, ensuring consistent motion trajectories for both machines.

- Precisely controls the flow and pressure of hydraulic oil through servo valves to achieve synchronized slider movement. Offers fast response and high precision, suitable for high-load conditions.

- Ensures real-time data interaction between the control systems of the two bending machines, typically using industrial Ethernet or dedicated communication protocols.

- Prevents uneven hydraulic pressure due to workpiece misalignment, ensuring balanced force distribution between the two machines.

GIVI MISURE

Italy Importaed Maganetic Ruler - Precise Postioning and On-time Reaction

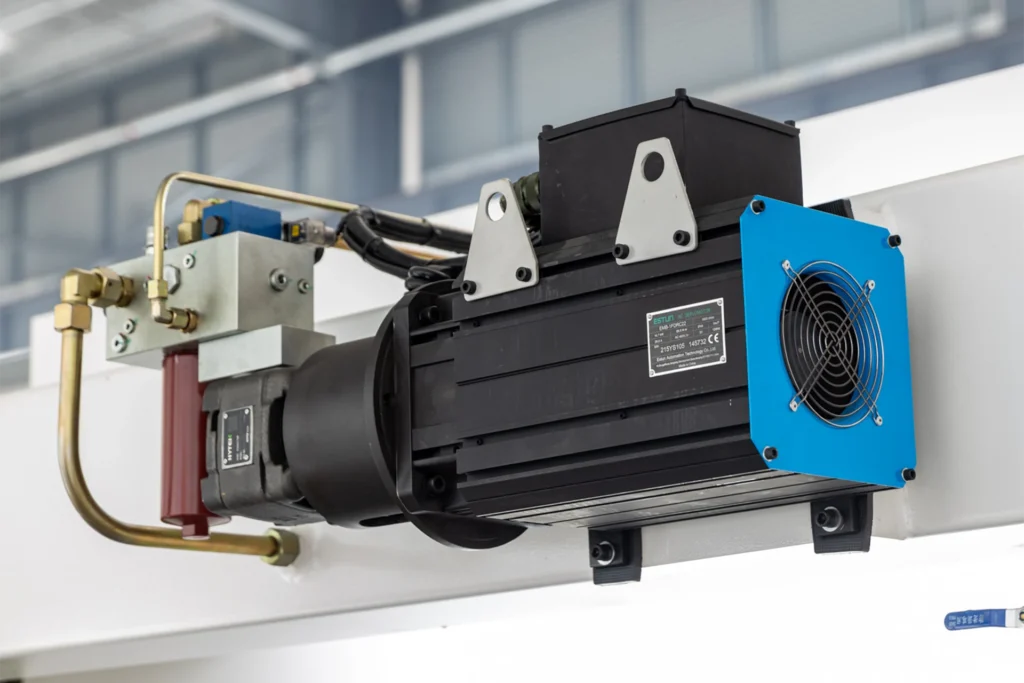

Fully ESTUN FULL SERVO/DRIVE System for Hydraulic Press Brake

Advantage:

- Precise Motion Control

- Dynamic Response

- Energy Management

- High Precision and Stability

- Fast Response

- Energy Efficiency &Easy Integration

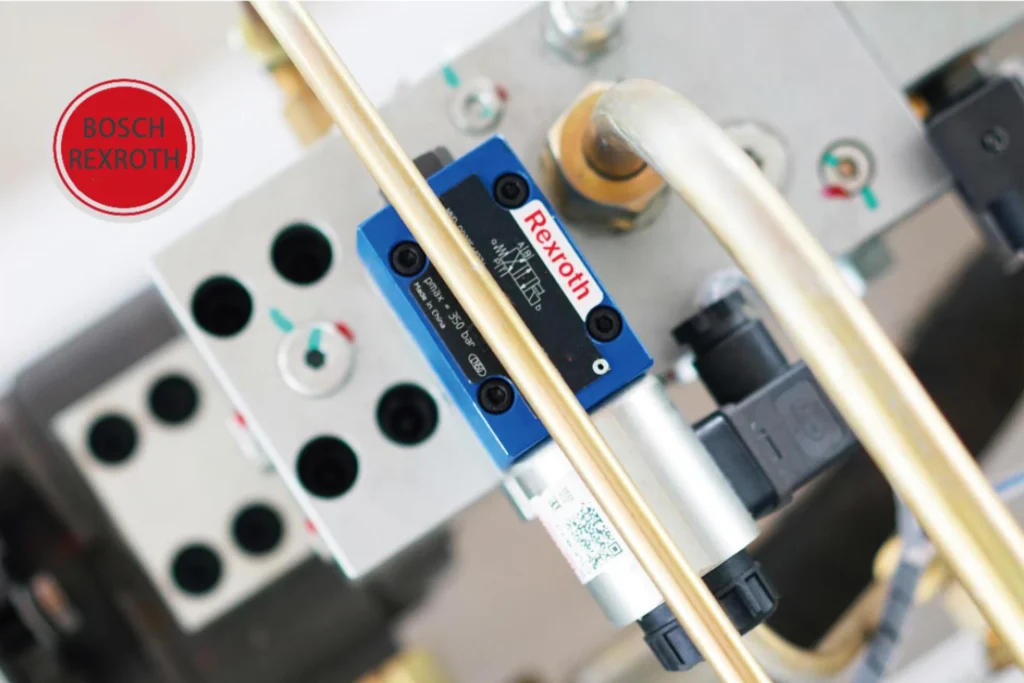

Germany BOSCH-REXROTH Hydraulic System

CAMT Party with Top-Tier Closed- Loop Control Technology

Advantage:

- Ensures machine stability and rigidity with strict inspections and finite element analysis.

- Delivers real-time feedback and micron-level precision.

- Boosts efficiency with 20% faster response than hydraulic systems.

- Eco-friendly design with regenerative power recovery.

- Advanced technology for superior performance.

- Automatic angle correction and collision prevention.

- Backed by professional engineers for lifelong assurance.

Bending Offline Programming Software

The Core Solution for Maximizing Sheet Metal Processing Efficiency

The DELEM DA Series Offline Programming Software significantly enhances press brake productivity and processing capacity through intelligent technology. The integrated Profile-T3D system delivers a complete offline programming environment with 3D bending process simulation capabilities.

Key Technical Advantages of Profile-T3D:

As an indispensable intelligent tool for modern sheet metal fabrication, Profile-T3D provides three core benefits: Rapid import and automatic unfolding of 3D engineering drawings; intelligent optimization of tool configuration and bending sequences; and advanced 3D dynamic simulation to preemptively detect collision risks, ensuring safe and reliable processing.

The Next-Gen Smart Manufacturing Automation Solution

Leverages the CAMT® intelligent control hub and Industrial IoT (IIoT) platform to achieve high-efficiency connectivity between devices, systems, and the cloud, creating a truly seamless digital production environment. With multi-protocol compatibility, plug-and-play interfaces, and cross-platform collaboration, it significantly enhances programming efficiency, data acquisition completeness, and remote response speed. Featuring standardized connectivity, secure data transmission, and flexible scalability, it has already helped hundreds of enterprises reduce integration costs and accelerate smart manufacturing transformation. Whether for CAD/CAM integration, real-time monitoring, or cloud collaboration, this solution provides reliable technological support to modern factories, making automated production smarter and more efficient.

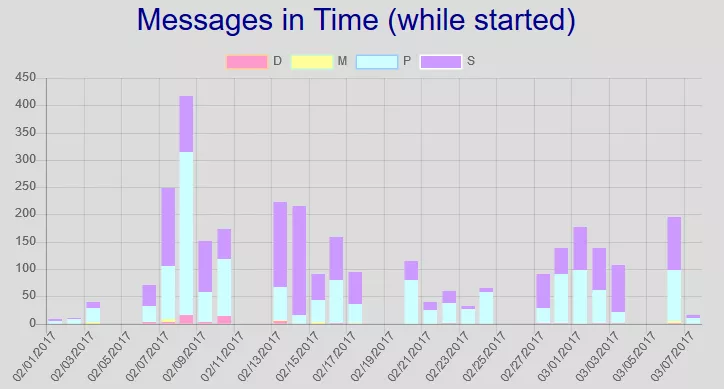

Runtime Message Monitoring

This bar chart displays statistics of various message types triggered during DA-Control operation. Only messages that were active during system runtime are recorded, including the following categories:

- D - Delem system application messages

- M - DM module messages

- P - Safety PLC generated messages

- S - Sequencer messages

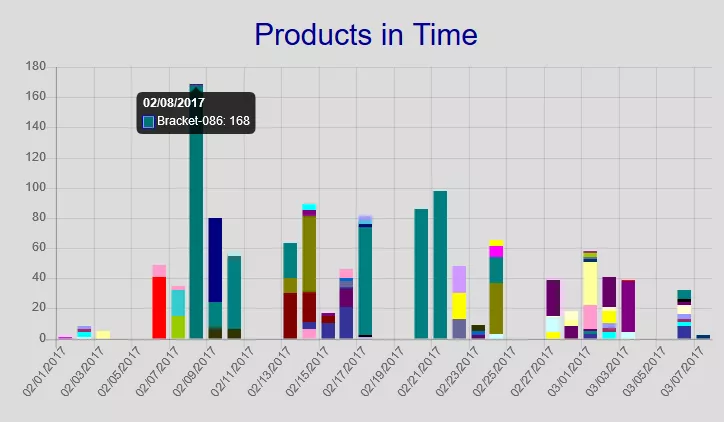

Product Production Timeline

This block presents daily production quantities for each product via bar charts. Hovering over any bar will display the product ID and specific production quantity for that date.