CAMT

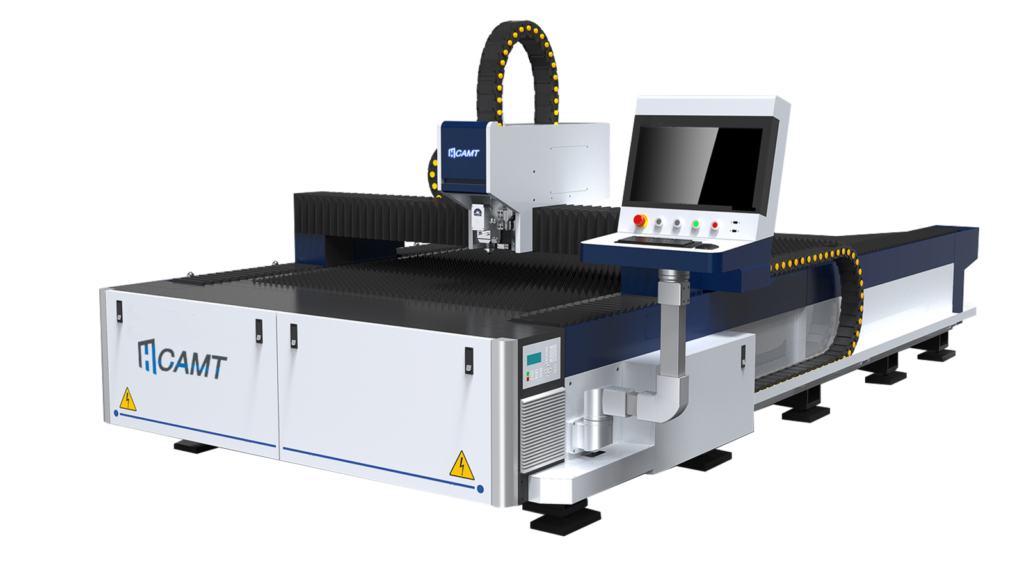

ULF Open-Type Single Desktop Fiber Laser Cutter

CAMT

Versatile 1~6KW Laser Sheet Metal Cutting Machine

High-Precision Laser Cutting Solution: Versatile, Efficient, and Durable"

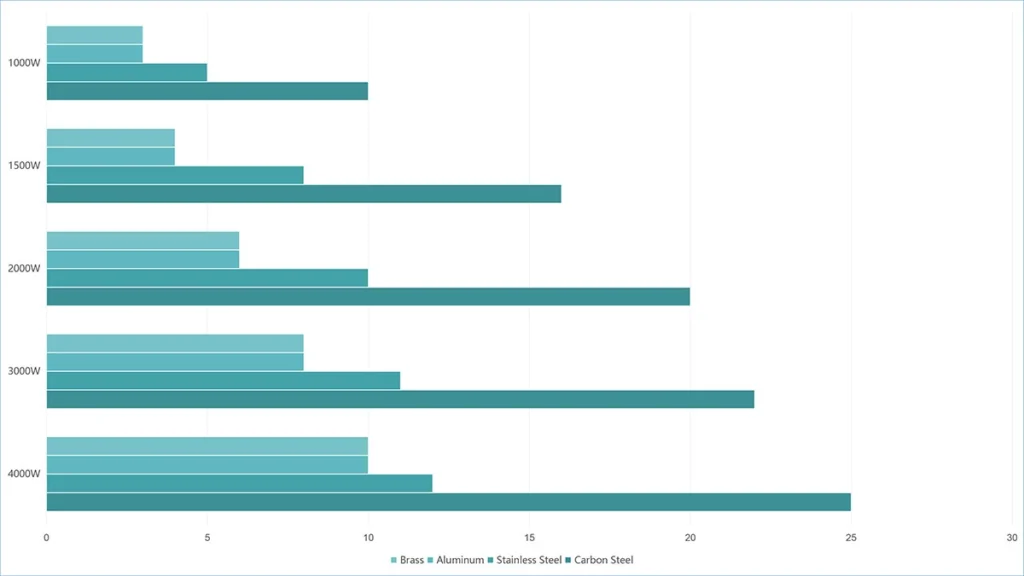

CAMT®️ advanced laser cutting machine, offered in various models, provides exceptional versatility to meet diverse metal processing needs, efficiently handling materials like carbon steel, stainless steel, galvanized sheet, aluminum alloy, brass, and titanium sheet. It is widely adopted in industries such as kitchen appliances, sheet metal chassis, automotive parts, medical equipment, and advertising signs. Equipped with a high-quality Japanese servo drive system, it ensures superior precision, stability, and operational efficiency. The machine delivers flawless, burr-free cuts at high speeds, significantly lowering production costs. Its compact, floor-standing gantry dual-drive structure is designed for ease of use, minimal maintenance, and space efficiency. The robust body, crafted through plate and tube welding and heat-treated at 600°C, guarantees no deformation for 20 years, offering long-term reliability and performance for modern metal processing applications.

ULF Open Type Single Desktop Fiber Laser Cutter

Incorporates the Following Attributes and Capabilities

Advanced Durability

Built with a high-strength, heat-treated frame for long-lasting performance and zero deformation over 20 years.

High Efficiency

Features a Japanese servo drive system for rapid, energy-saving cuts that boost productivity.

Flawless Cutting

Delivers burr-free, precise cuts on diverse metals, ideal for high-quality production needs.

Low Maintenance

Designed for minimal upkeep with a user-friendly structure, reducing long-term operational costs.

Why CAMT Laser Cutting?

Unmatched Durability

Utilizing premium materials and rigorous testing to ensure long-term resilience under heavy industrial use.

Innovation Leadership

Investing in research and advanced engineering to adapt to evolving market demands and introduce cutting-edge features.

Customer-Centric Solutions

Designing compact, space-saving machines with user-friendly features to enhance accessibility and operational flexibility.

Enhanced Productivity

Offering high-speed cutting capabilities and optimized workflows to minimize downtime and reduce overall production costs.

Commitment to Quality

Implementing low-maintenance designs with durable components, supported by excellent service to maintain consistent performance.

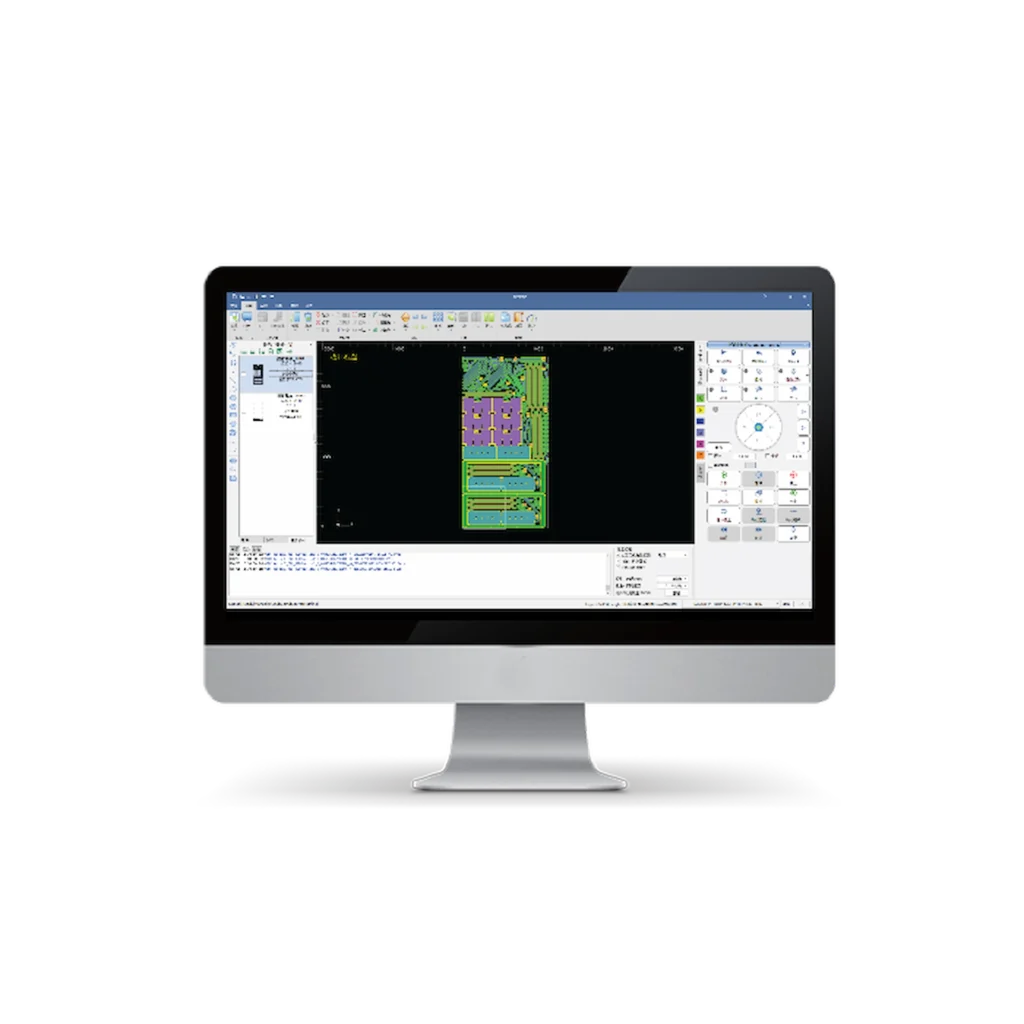

Professional Laser Cutting Control System

Integrates file reading, design output and processing control. A set of software can complete the whole process from design to processing.

- Based on Windows operation development

- Support a variety of file rich layer interface

- Simple and practical cutting software

- Real-time frequency and power curve

Most Popular RAYCUS Laser Source

Using ytterbium (Yb)-doped fiber as the gain medium, pumped by semiconductor laser diodes to generate high-power laser beams.

Working Mechanism

Involves the pump light exciting the doped ions in the fiber, producing photon oscillation and amplification within the fiber, and finally outputting a high-intensity laser beam through a resonant cavity.

Optical-electrical conversion and thermal management capabilities of fiber optics.

Proprietary solution for viewing reports of machine status and analyzing production data.

High-power Output

The output laser has excellent focusability, ensuring high cutting precision with smooth, burr-free edges.

Advantages:

•High Efficiency and Stability.

•Superior Beam Quality

•Strong Adaptability

•Compact and Flexible Design

Terms of applications

Enables precise cutting of various materials, including carbon steel, stainless steel, and aluminum alloys, achieving efficient, non-contact processing.

RAYTOOLS Laser Cutting Machine Head

Focusing a laser beam via optical lenses, with the beam from a fiber laser source collimated and directed onto the workpiece. A dynamic height sensor adjusts the focal point for consistent cutting across uneven surfaces, while a protective lens and gas system shield optics and remove molten material. They excel in precise, high-speed cutting of metals like carbon steel and aluminum, serving industries such as automotive and manufacturing with clean cuts and minimal heat impact.

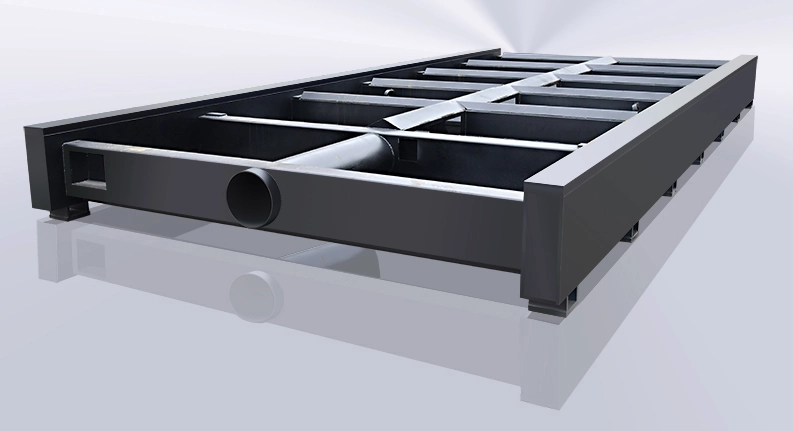

Mortise and tenon structure and heat treatment of laser cutting machine

The annealing process of the whole machine to eliminate the internal stress, and the large-scale shot blasting process The steel plate is welded, and the tempering treatment bed has stronger rigidity, long service life and no deformation more than 20 years.

- Humanized design, more practical user experience. Simple operation The control system is simple to operate and easy to learn with more comprehensive compatibility, more flexible and effective processing. High precision, with high production and processing quality.

- Processing can carry out multi axis coordination, easily produce complicated designs. When machining parts are changed, generally only a program be written, which can save production site management time and save human capital work.

- The rigidity is large and the output rate is high; the feeding and unloading is very convenient and can alleviate the labor efficiency.

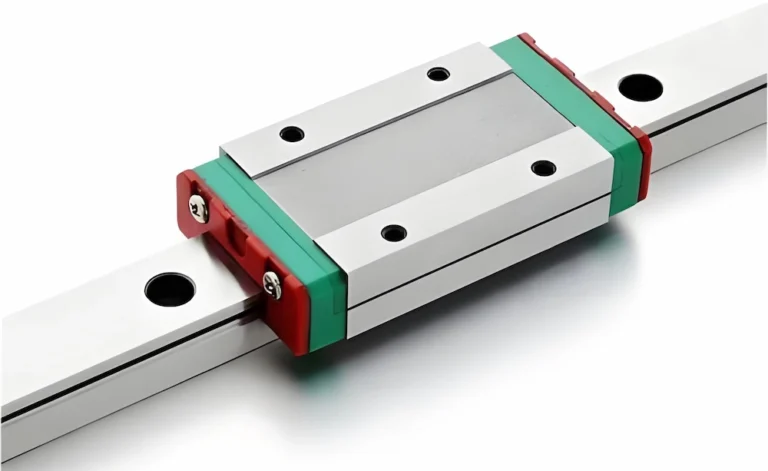

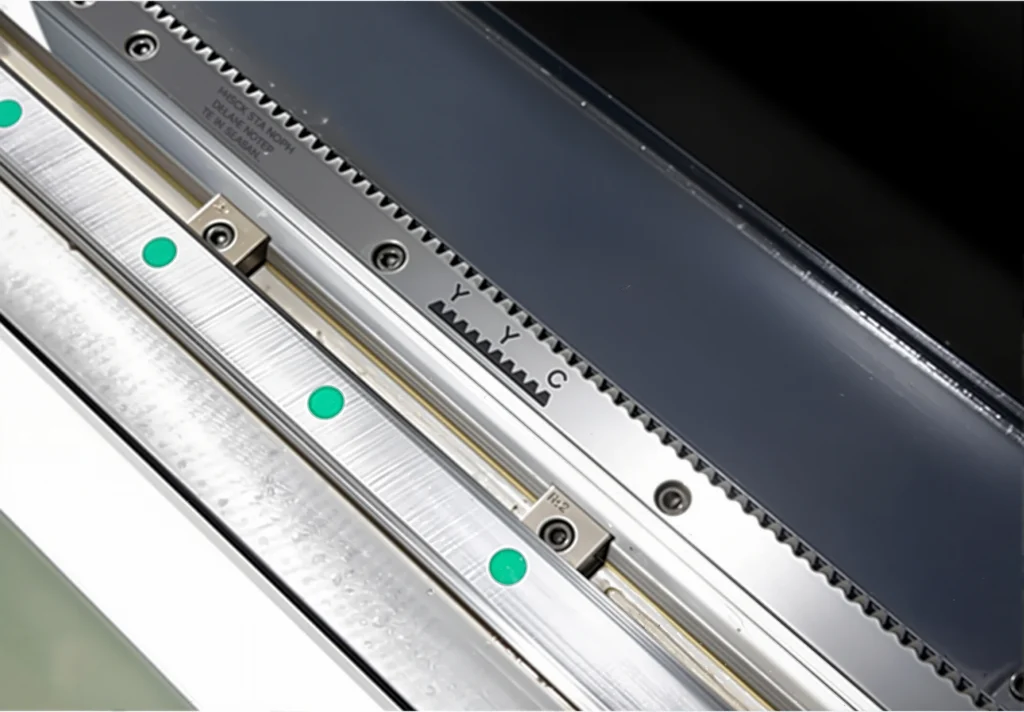

Enhanced Precision and Stability

HIWIN guides ensure μm-level accuracy with low-friction rolling motion, while YYC racks (European Grade 6) minimize backlash for consistent, high-quality cuts.

Improved Efficiency and Speed

HIWIN’s low-friction design enables rapid, slip-free motion, and YYC racks support high-speed linear motion, boosting productivity.

Durability and Longevity

HIWIN guides, with 70 HRC hardness, resist wear, and YYC racks endure heavy loads, ensuring long-term reliability in tough conditions.

Versatility Across Applications

HIWIN guides handle multi-directional loads and self-align, while YYC racks (straight/helical) suit various machines, offering flexibility.

INOVANCE Servo Motors & Drivers for Fiber Laser Cutter

Ensuring accurate laser beam movement for complex sheet or tube processing, while enhancing dynamic response and multi-axis coordination.

Advantage:

- Precise Motion Control

- High-Speed Performance

- Enhanced Stability and Smooth Operation

- Energy Efficiency and Low Heat Generation

- Reliability and Low Maintenance

- Stability and Durability

- Strong Adaptability

HANLI Cooling System for Laser

Cooling systemhas good quality and high temperature control accuracy; stable and reliable performance, low failure rate, energy saving and power saving; personalized design, etc.

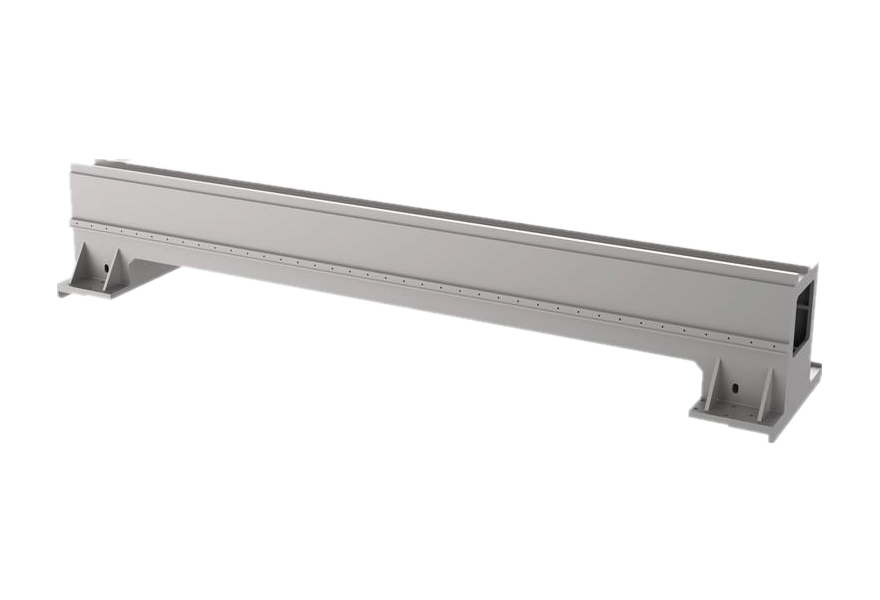

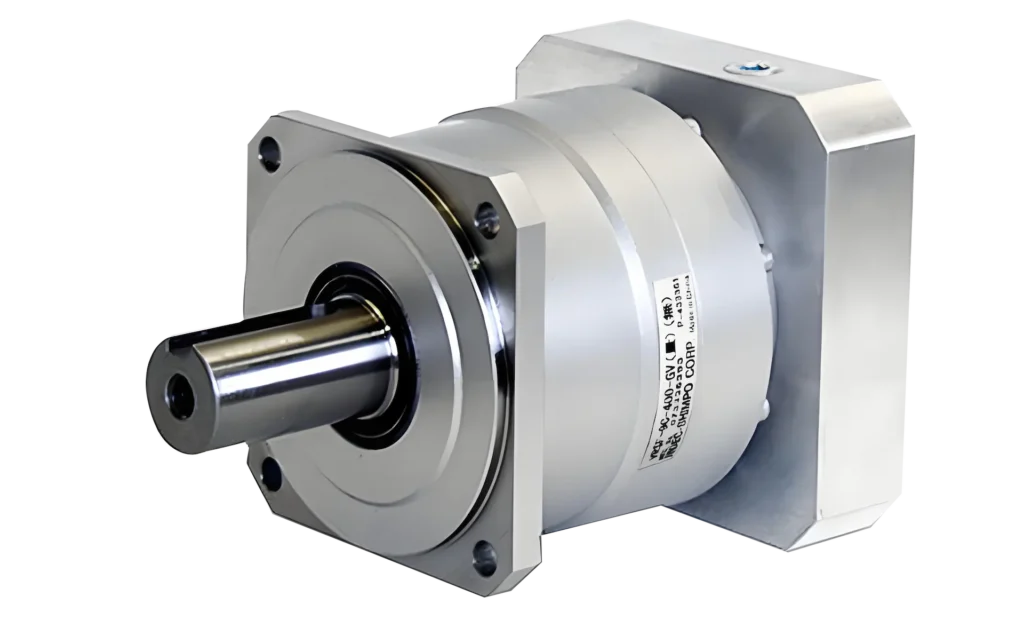

Superior Performance Parts for Stability

- Using honeycomb structure beam design high strength, high rigidity, light weight

- SHIMPO reducer with high precision, silent, long life, no oil leakage, large torque and other fine characteristics.

CAMT Laser Cutting Machine Quality

CAMT made by laser cutting can basically be used only once, and can be used directly without other post-processing, so that the processing technology of the product has been well optimized. In addition, the edges of the cut product will not have sags or burrs, and the surrounding thermal deformation is relatively small, so small that it can be ignored.

By understanding the advantages of laser cutting, we know that many processing advantages cannot be achieved by traditional mechanical processing, and these advantages of laser cutting are exactly what we need for processing now, so laser cutting just goes with the flow. It has become the most popular and most used processing method in the processing industry.

High Performance Technical Specification of CAMT Laser

Parameter

- Max. Running Speed 120M/MIN

- X/Y Location Precision 0.01MM

- X/Y Repeated Location Precision 0.03MM

- Machine Gross Power <10KVA

- Running Humidity < 90%

- Max. Accelerated Speed 1.5G