CAMT

ULW Portable Laser Welding Machine

CAMT

ULW Portable Laser Welding Machine

Hand-Held Fiber Laser Welding Machine: Efficient, Cost-Saving, and Versatile

CAMT offers continuous light emission, high electro-optical conversion efficiency, and a long laser life, requiring no maintenance, adjustments, or consumables, which, combined with low energy consumption, significantly reduces processing costs over time compared to traditional methods like soldering or argon arc welding that rely heavily on consumables such as solder, gas, wire, salt, and acid. Its compact structure, small size, and built-in water cooling system provide flexibility and convenience for hand-held welding, including outdoor applications. The machine is simple to operate and easy to learn, suitable for both novices and skilled workers, addressing the current challenges of labor shortages and rising wage costs. With a high working efficiency that is 10-15 times faster than conventional welding methods like soldering or argon arc welding—known for low efficiency and operator fatigue—it breaks through traditional limitations.

Simple Operation

Hand-held Portable

Continuous Light Emission

Working Efficiency

Why CAMT Laser Cutting?

Unmatched Durability

Utilizing premium materials and rigorous testing to ensure long-term resilience under heavy industrial use.

Innovation Leadership

Investing in research and advanced engineering to adapt to evolving market demands and introduce cutting-edge features.

Customer-Centric Solutions

Designing compact, space-saving machines with user-friendly features to enhance accessibility and operational flexibility.

Enhanced Productivity

Offering high-speed cutting capabilities and optimized workflows to minimize downtime and reduce overall production costs.

Commitment to Quality

Implementing low-maintenance designs with durable components, supported by excellent service to maintain consistent performance.

Laser Welding Equipment

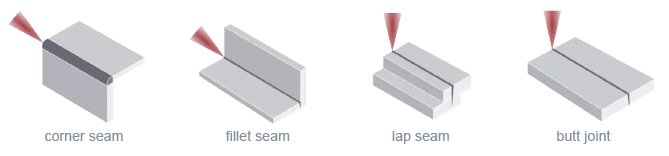

Hand-held laser welding machines can be widely used in complex and sophisticated welding processes in cabinets, kitchen equipment, elevator industries, shelves, door and window guardrails, electrical cabinets, household appliances and other industries.

Compared with traditional arc welding, handheld laser welding has the advantages of simple operation, beautiful welding seam, solid welding, small deformation of workpiece, reduce grinding workload, low maintenance and use cost of equipment.

Technical Parameter

| ITEM | HMW-1000 | HMW-1500 | HMW-2000 | Remark |

|---|---|---|---|---|

| Welding material & thickness | 1000W welding capacity ≤2mm stainless steel; mild steel; <1mm Aluminum Plate, Galvanized Plate |

1500W welding capacity ≤3mm stainless steel; mild steel; <1.5mm Aluminum Plate, Galvanized Plate |

2000W welding capacity ≤4mm stainless steel; mild steel; <2mm Aluminum Plate, Galvanized Plate |

|

| Performance Index Parameters | ||||

| 1. Laser Source | Raycus | 1000-2000 | ||

| 2. Laser Cutting Head | Wobble Welding head | CAMT | ||

| 3. Welding Material Thickness | 0.5-3mm | Based on material, customized Available | ||

| 4. Welding Move | 0.2-1.5mm | Adjustable | ||

| 5. Automatic Lick Silk | Standard silk 1.2mm | Selective | ||

| 6. Working Temperature | 0-40℃ | |||

| 7. Humidity | <85% | |||

| 8. Stable Voltage | 220V 50HZ 20A | According to customer local voltage | ||

| 9. Cooling system | Hanli water cooling machine | |||

| Additional Specifications | ||||

| Power | Single Phase 220 20A (Main Circuit Breaker) 10M Power Cable |

|||

| Compressor air/O2/N2 | Air Pressure: >0.2Mpa; <1Mpa; Tube Dia: 6MM | |||

| Environment Temperature | 25±5 ℃ | |||

| Humidity | 30-70% RH | |||

| Wearing Parts | ||||

| Item | Model | Suggested Working Time | ||

| Welding nozzle | China | 1 Month | ||

| Protective Glasses | China | 1 Month | ||

Why CAMT Welding Machine

| Comparison/Project | Traditional ARC Welding | Ordinary handle Welding | HMW-Fiber Laser Welding |

|---|---|---|---|

| Workpiece heat input | Very High | LOW | LOW |

| Deformation of the workpiece | High | LOW | LOW |

| The welding quality | Bad | Good | Perfect |

| Subsequent processing | Polishing | No | No |

| Welding speed | Bad | 2 Times ARC Welding | 2 Times Welding |

| consumables | High | Low | Low |

| Operation difficulty | Hard | Hard | Simple |

| Welding fault tolerance | Good | Bad | Perfect |

| Swing welding | NO | No/Expensive | Standard |

| The welding width adjustable | NO | No/Expensive | Standard |

| Worker safety design | NO | NO | Included and Improving |