Principle and Function of Press Brake Safety Protection System

Principle and Function of Press Brake Safety Protection System Why Press Brake Safety Protection Matters In modern metal fabrication, the press brake remains one of the most indispensable yet potentially hazardous machines on the shop floor. While advancements in CNC control, servo technology, and tooling precision have significantly improved bending accuracy, operator safety continues to be a critical concern. According to industry safety statistics, a large proportion of serious press brake accidents occur during the closing stroke, when hands, tools, or workpieces enter the danger zone beneath the upper punch. To address this risk, press brake manufacturers and safety solution providers have developed advanced press brake safety protection systems. Among […]

Press Brake Maintenance and Repair

Press Brake Maintenance and Repair Press brake maintenance and repair play a decisive role in the long-term performance of a bending machine. In actual factory conditions, many problems that appear to be sudden failures are in fact the result of accumulated wear, insufficient lubrication, or delayed inspection. A press brake is a high-load, high-precision machine, and its condition directly affects bending accuracy, production efficiency, and overall operating cost. From an engineering perspective, maintenance is not only about preventing breakdowns. It is also about maintaining stable accuracy over time. Machines that are cleaned, lubricated, and inspected regularly tend to show predictable behavior, making process control much easier. In contrast, machines that […]

Practical Methods for Press Brake Accuracy with Long Term Precision

A technical guide explaining press brake accuracy adjustment, focusing on guideway alignment and backgauge precision, written for practical use in real production environments.

Practical Guidance For Press Brake Operation

Practical Guidance For Press Brake Operation Introduction to Press Brake Operation Press brake operation is one of the most critical processes in sheet metal fabrication. Regardless of machine brand or control system, bending accuracy and repeatability depend largely on how the machine is operated rather than on the machine itself. Even advanced CNC press brakes require correct setup, proper tooling installation, and reasonable parameter adjustment to perform reliably in daily production. In practical manufacturing, many bending problems such as angle deviation, unstable consistency, or excessive tool wear are not caused by mechanical failure. They usually result from incorrect operation, insufficient understanding of tooling behavior, or neglect of material variation. This article […]

How to Properly Install a Press Brake Machine

How to Properly Install a Press Brake Machine Understanding the Importance of Proper Press Brake Installation A press brake machine is a precision forming machine, and its installation quality directly influences bending accuracy, repeatability, and long-term mechanical stability. In real production environments, many performance issues that appear to be related to machine quality are actually caused by improper installation. For this reason, installation should be approached as a technical process rather than a simple positioning task. Correct installation minimizes internal stress within the machine frame, ensures even force distribution during bending, and provides a stable base for hydraulic and electrical systems. Especially for CNC press brakes, even small installation errors […]

Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance

Press Brake Safety Precautions: Complete Guide for Safe Operation and Maintenance Introduction: Why Press Brake Safety Precautions Matter A press brake machine is a critical piece of equipment in sheet metal fabrication. Proper installation, correct operation, and regular maintenance are essential not only for product quality but also for operator safety and machine longevity. Before installing, operating, or servicing any hydraulic or CNC press brake, operators must fully understand the safety precautions outlined in the operation manual. This guide expands on key press brake safety requirements to help users operate their machines safely and efficiently. 1. Read the Press Brake Operation Manual Before Installation and Use Before any press brake […]

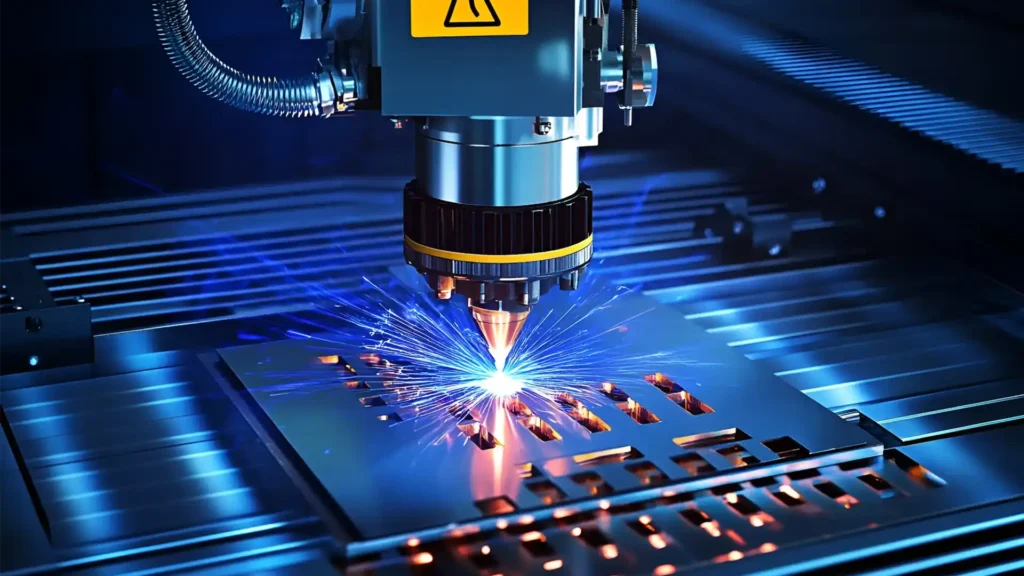

How to Use Bochu Laser Cutting System Edge Finding Function

How to Use Bochu Laser Cutting System Edge Finding Function The Bochu laser cutting system (also known as FSCUT from Friendess or Shanghai Bochu Electronic Technology) is one of the most widely used control systems for fiber laser cutting machines in the sheet metal fabrication industry. It is a fully featured open-loop (and in higher models, bus-based) control system designed specifically for precision metal processing. A key feature that most operators rely on during sheet metal cutting is the edge finding (or “edge seeking”) function, particularly the capacitive edge finding method. This feature automatically detects the sheet’s edges, calculates any rotation angle if the material is placed skewed, and adjusts […]

E21 Press Brake System Operation Manual

E21 Press Brake System Operation Manual Harmon Tech E21 press brake controller is a reliable and cost-effective NC system commonly used in torsion bar hydraulic press brakes. It provides precise control over the Y-axis (ram depth for bending angle) and X-axis (back gauge positioning), making it ideal for sheet metal bending operations. This guide offers a professional, step-by-step explanation of the E21 system operation, helping operators achieve accurate bends while addressing common issues. I. Operation Procedure of E21 Press Brake Power-On Preparation Before starting the E21 press brake, perform these essential checks to ensure safe and efficient operation: Verify the power supply: 380V three-phase electricity, stable and properly grounded. Check […]

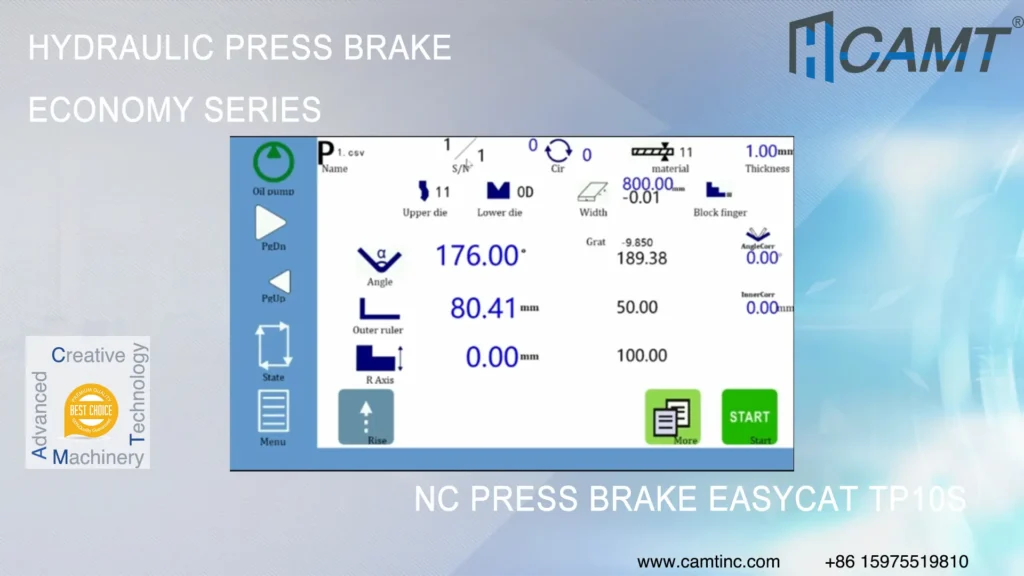

NC Press Brake EASYCAT TP10S System Manual

NC Press Brake EASYCAT TP10S System Manual 1. TP10S System Overview The NC Press Brake EASYCAT TP10S is a reliable, cost-effective 10.1-inch full-color touchscreen CNC system developed specifically for Wuxi Isket WC67K-series torsion-bar synchronized hydraulic press brakes (40–400 Ton, 1.6–6 m length). It delivers ±0.05 mm repeatability through proven torsion-bar + dual-servo backgauge technology and is widely used for stainless steel, aluminum, mild steel, and galvanized sheet fabrication in electrical cabinets, automotive parts, kitchen equipment, and general sheet metal workshops. Key Advantages 10.1″ TFT 256K color touchscreen (Chinese/English) Standard 4+1 axes (Y1-Y2-X-R + torsion sync), expandable to 6+1 Fast servo X-axis (faster than most E21/DA41T systems) 220 programs × 24 […]

CYPCUT Laser Cutting Software Operation Manual

CYPCUT Laser Cutting Software Operation Manual Introduction to the CYPCUT Laser Cutting Software The CYPCUT laser cutting software, developed by Friendess (also known as Bochu or FSCUT), is a powerful and user-friendly control system specifically designed for fiber laser cutting machines. This intuitive platform streamlines the entire process from design to execution, making it ideal for both beginners and experienced operators in the laser cutting industry. The interface features a clean, ribbon-style layout that enhances productivity by providing quick access to essential tools and functions. Key components of the CYPCUT interface include: Drawing Board: The central black workspace where graphics are displayed and edited. A white frame outlines the machine’s […]