This bar chart displays statistics of various message types triggered during DA-Control operation. Only messages that were active during system runtime are recorded, including the following categories:

ULW Portable Laser Welding Machine

This bar chart displays statistics of various message types triggered during DA-Control operation. Only messages that were active during system runtime are recorded, including the following categories:

ULW Portable Laser Welding Machine

Perfect

Subsequent processing.

No

Welding speed

2 Times ARC Welding

2 Times Welding

consumables

Low

Operation difficulty.

Hard.

Hard.

Simple

Welding fault tolerance.

Swing welding.

Swing welding.

NO

No/Expensive.

Standard.

Standard.

The welding width adjustable

Worker safety design.

Included and Improving.

Included and Improving.

breadcrumbs

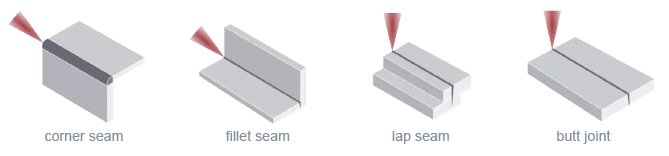

Terms of applications.

Enables precise cutting of various materials, including carbon steel, stainless steel, and aluminum alloys, achieving efficient, non-contact processing.

Enables precise cutting of various materials, including carbon steel, stainless steel, and aluminum alloys, achieving efficient, non-contact processing.

Laserschweißgeräte

Handgeführte Laserschweißgeräte können in komplexen und anspruchsvollen Schweißprozessen in Schränken, Küchengeräten, der Aufzugsindustrie, Regalen, Tür- und Fenstergeländern, Schaltschränken, Haushaltsgeräten und anderen Industrien weit verbreitet eingesetzt werden.

Im Vergleich zum traditionellen Lichtbogenschweißen bietet das handgeführte Laserschweißen die Vorteile einer einfachen Bedienung, einer schönen Schweißnaht, einer soliden Schweißung, einer geringen Verformung des Werkstücks, einer reduzierten Schleifarbeit sowie niedriger Wartungs- und Betriebskosten der Ausrüstung.

Cutting speed

| ARTIKEL | HMW-1000 | HMW-1500 | HMW-2000 | Bemerkung |

|---|---|---|---|---|

| Schweißmaterial & Dicke | 1000W Schweißkapazität ≤2mm Edelstahl; Baustahl; <1mm Aluminiumplatte, verzinktes Blech |

1500W Schweißkapazität ≤3mm Edelstahl; Baustahl; <1.5mm Aluminiumplatte, verzinktes Blech |

2000W Schweißkapazität ≤4mm stainless steel; mild steel; <2mm Aluminum Plate, Galvanized Plate |

|

| Performance Index Parameters | ||||

| 1. Laser Source | Raycus | 1000-2000 | ||

| 2. Laser Cutting Head | Wobble Welding head | This bar chart displays statistics of various message types triggered during DA-Control operation. Only messages that were active during system runtime are recorded, including the following categories: | ||

| 3. Welding Material Thickness | 0.5-3mm | Based on material, customized Available | ||

| 4. Welding Move | 0.2-1.5mm | Adjustable | ||

| 5. Automatic Lick Silk | Standard silk 1.2mm | Selective | ||

| 6. Working Temperature | 0-40℃ | |||

| 7. Humidity | <85% | |||

| 8. Stable Voltage | 220V 50HZ 20A | According to customer local voltage | ||

| 9. Cooling system | Hanli water cooling machine | |||

| Additional Specifications | ||||

| Power | Single Phase 220 20A (Main Circuit Breaker) 10M Power Cable |

|||

| Compressor air/O2/N2 | Air Pressure: >0.2Mpa; <1Mpa; Tube Dia: 6MM | |||

| Environment Temperature | 25±5 ℃ | |||

| Humidity | 30-70% RH | |||

| Wearing Parts | ||||

| Artikel | T-Bar | Suggested Working Time | ||

| Welding nozzle | China | 1 Month | ||

| Protective Glasses | China | 1 Month | ||

Why CAMT Welding Machine

| Comparison/Project | Traditional ARC Welding | Ordinary handle Welding | HMW-Fiber Laser Welding |

|---|---|---|---|

| Workpiece heat input | Very High | LOW | LOW |

| Deformation of the workpiece | High | LOW | LOW |

| The welding quality | Bad | Good | Perfect |

| Subsequent processing | Polishing | No | No |

| Welding speed | Bad | 2 Times ARC Welding | 2 Times Welding |

| consumables | High | Low | Low |

| Operation difficulty | Hard | Hard | Simple |

| Welding fault tolerance | Good | Bad | Perfect |

| Swing welding | NO | No/Expensive | Standard |

| The welding width adjustable | NO | No/Expensive | Standard |

| Worker safety design | NO | NO | Included and Improving |